TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4

Page 31

GN2 Purge System

Note: Refer to the Installation Instructions Section for supply and connection type specifications.

Warning! Gaseous nitrogen displaces oxygen. Make sure the area surrounding the chamber is

well ventilated to dilute the gas vented from the chamber vent port checkvalve!

General Description:

As an option, your chamber may be equipped with a GN2 Purge System to provide an inert atmosphere

inside the chamber. An inert atmosphere minimizes the buildup of moisture and prevents condensation on

the product under test. Eliminating oxygen in the chamber air helps prevent corrosion of the product.

Gaseous nitrogen is injected into the chamber through a header pipe in the conditioning plenum. It readily

mixes in with the circulating process air.

Operation:

The system is activated by an event output from the main controller (or by a manual switch). To use the

system, the Event must be turned ON. Reference the Event Label on the side of the chamber or your Test

Report for the Event Number assigned to this feature.

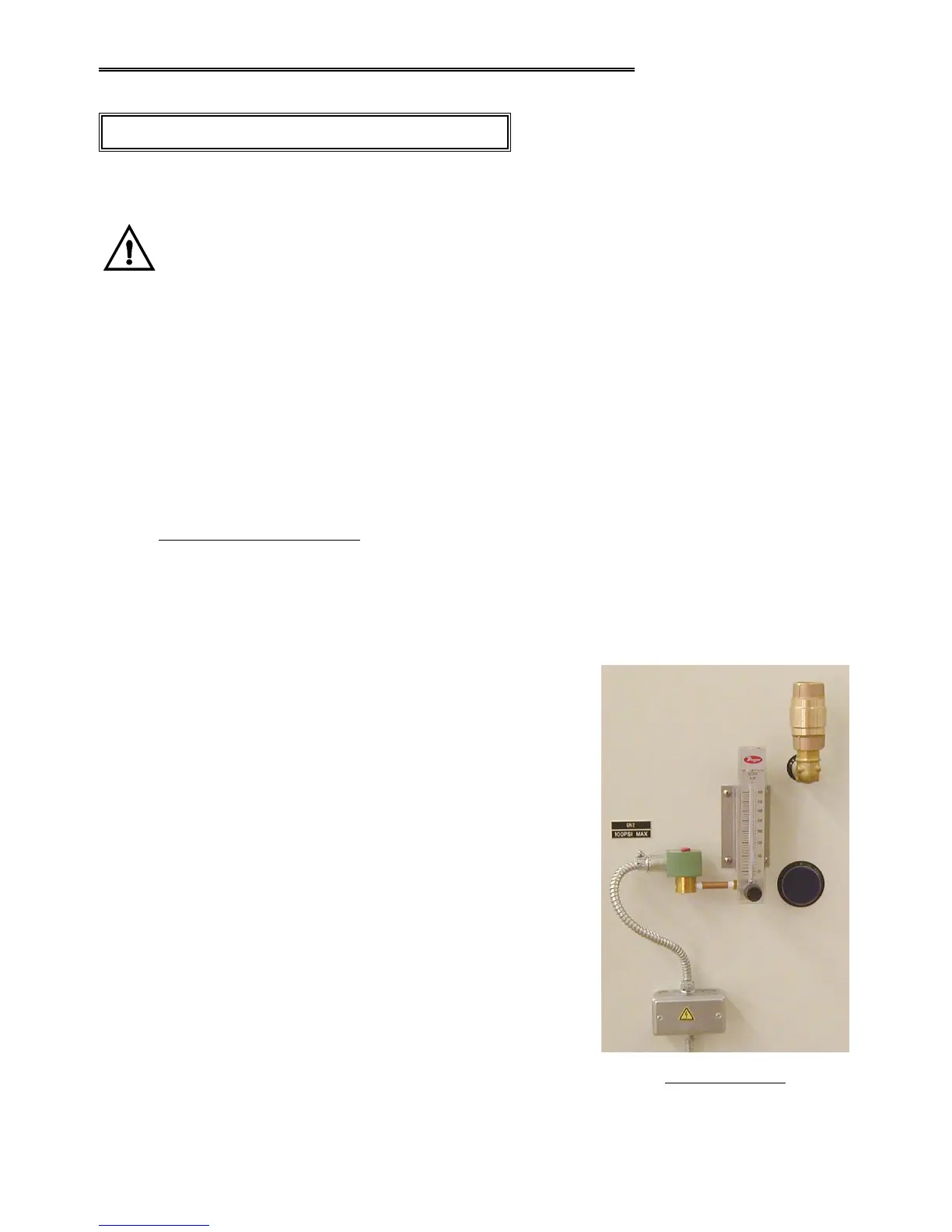

When activated, the event output will energize and open the GNSOL solenoid valve to permit the injection of

GN2. A metering valve and flowmeter is supplied as part of the system to establish the design purge flow.

The valve should be adjusted until the indicated flow is about 300 cubic feet per hour.

Note: Your equipment configuration may be slightly different from

what is shown.

14.0 GN2 PURGE AIR SYSTEM (Optional)

Loading...

Loading...