TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4

Page 32

Note: Refer to the Installation Instructions Section for supply and connection type specifications.

Warning! Gaseous nitrogen resulting from vaporized LN2 displaces oxygen. Make sure the area

surrounding the chamber is well ventilated to dilute the gas vented from the chamber vent port

checkvalve!

General Description:

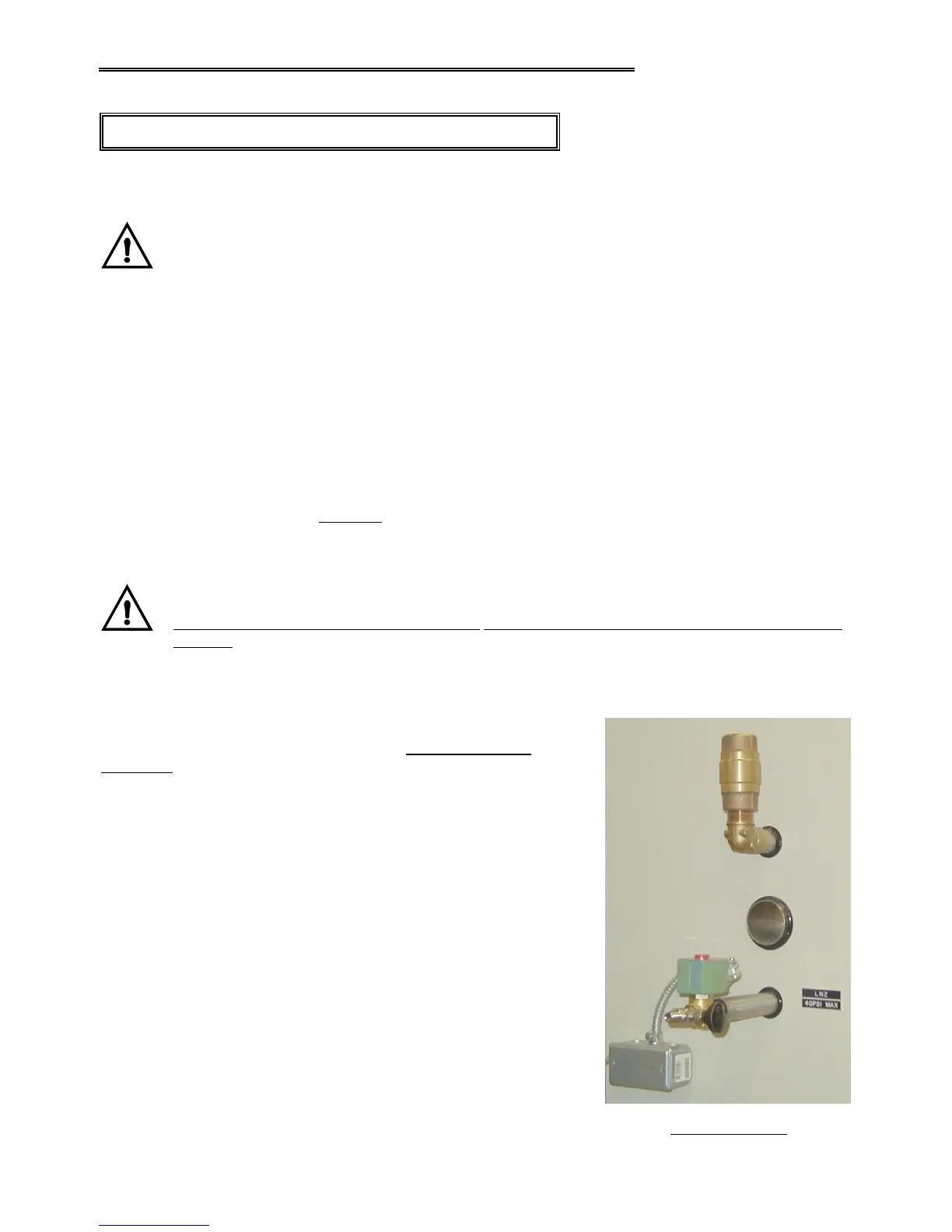

The LN2 Boost Cooling System option may be provided to increase the rate or limit of cooling beyond the

means of the refrigeration system. Boost cooling is achieved by injecting liquid nitrogen into the chamber

through a port located on the bottom left side. LN2 has a boiling point of -196 degrees Celsius (-320 deg. F).

As the liquid sprays out of the port, it vaporizes and absorbs chamber heat while it mixes with process air. A

small metal deflection flange is mounted about an inch away from the LN2 port to deflect any liquid nitrogen

spray from hitting the product before it vaporizes.

LN2 systems are provided with a manually set flow adjustment valve, which permits the adjustment of

nitrogen flow to avoid incomplete evaporation at varying LN2 supply pressures. As the chamber cools to the

extreme cold temperature limit, complete evaporation of liquid nitrogen may not occur if the supply pressure

is allowed to drop.

Important! Incomplete evaporation will cause droplets of liquid to fall to the floor and may

promote puddling. If enough liquid accumulates, it may seep towards the chamber door gasket.

Do not allow LN2 to contact the door gasket. Exposure to LN2 will damage the gasket and violate

the seal.

Operation:

The system is activated by an event output from the main controller

(or by a manual switch). To use the system, the Event must be

turned ON. Reference the Event Label on the side of the chamber or

your Test Report for the Event Number assigned to this feature.

Once the system is enabled with the event output, the controller's

time proportioned Full Cooling output will energize a solid state On-

delay timer. If the Full Cooling output remains on longer than ten

seconds, the timer will time out and energize the LN2 Injection

solenoid valve SOL. This valve will open to permit the flow of LN2

into the chamber to boost the cooling rate. As soon as the Full

Cooling output turns off, the timer output will open to deenergize SOL

and shut off the flow of LN2.

Note: Your equipment configuration may be slightly different from

what is shown.

15.0 LN2 BOOST COOLING SYSTEM (Optional)

LN2 Boost Cooling

Loading...

Loading...