November 2006

28 AL4000 Light Tower Part No. 833002 Rev A

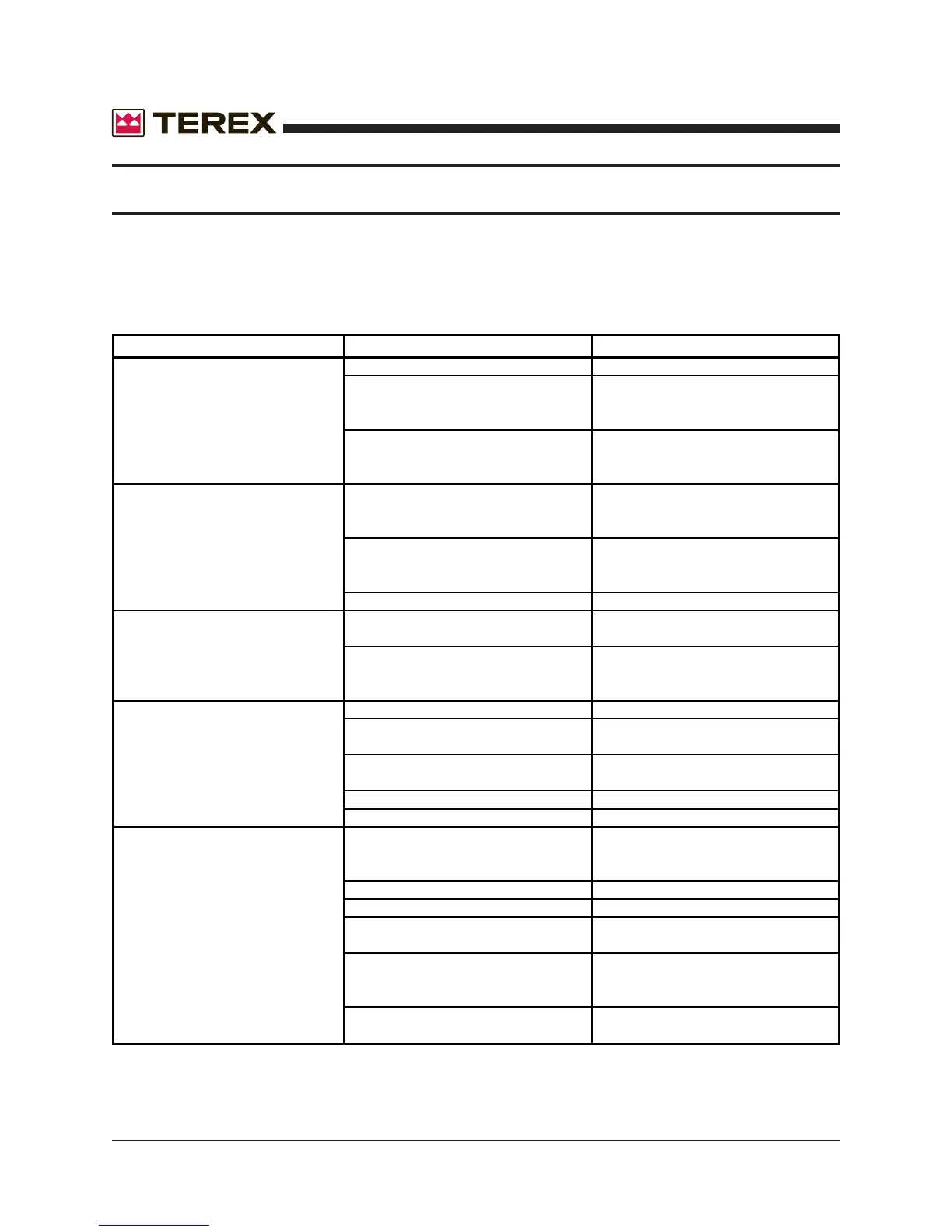

TROUBLESHOOTING

The engine and generator are set at the factory. These units are tested and set to 1800

RPM at 60 HZ for proper operation in the field. These units should never require additional

adjustments in the field. Adjustments should only be made by a qualified service technician,

otherwise the manufacturer’s warranty may become void.

TROUBLE POSSIBLE CAUSE REMEDY

1.Boom will not rise to a.Yoke pin is in place a.Remove yoke pin

the operating position. b.Defective cable b.Have a trained

or pulley mechanic examine and

repair as needed

c.Defective winch c.Have a trained

mechanic examine

and replace as needed

2.Boom will not telescope. a.Defective winch a.Have a trained

mechanic examine

and replace as needed

b.Broken cable or pulley b.Have a trained

mechanic examine

and replace as needed

c.Telescope lock pin closed c.Open telescope lock pin

3.Engine will not turn over a.Dead battery a.Check the battery voltage or

loose cables

b.Engine has seized due to loss b.Have a trained

of fluids mechanic examine and

repair as needed

4.Engine turns over but will a.Empty fuel tank a.Fill tank with #2 diesel fuel

not start b.Clogged fuel lines or filter b.Check and clean the fuel

system as needed

c.Leaking fuel lines or a loss c.Replace any leaking fuel lines

of prime and tighten connections

d.Heater elements burned out d.Replace heater elements

e.Fuel line solenoid is not open e.Replace fuel line solenoid

5.Engine runs rough a.Clogged or leaking fuel system a.Replace fuel lines, tighten all

connections, inspect the pickup

tube and inspect the fuel filter

b.Clogged exhaust system b.Clear the exhaust system

c.Clogged air filter c.Clear air filter

d.Clogged or stuck fuel injectors d.Have a trained

mechanic examine

e.Valve clearances are out of e.Have a trained

adjustment or the valve spring mechanic examine

may be damaged

f.Defective governor or fuel pump f.Have a trained

mechanic examine

Loading...

Loading...