BHT-206A/B-SERIES-MM-1

5-00-00

Page 144 Rev. 14 30 APR 2013

Export Classification C, ECCN EAR99

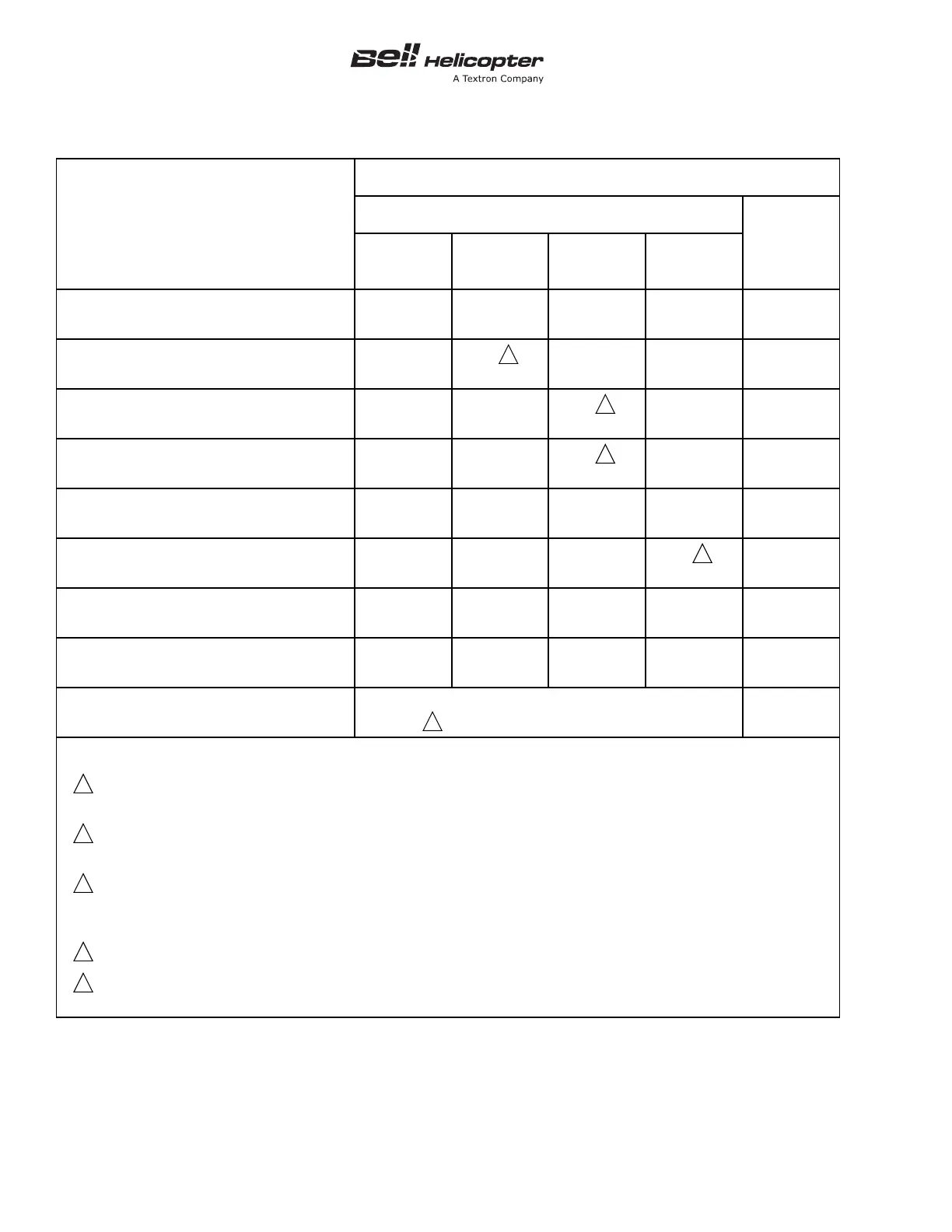

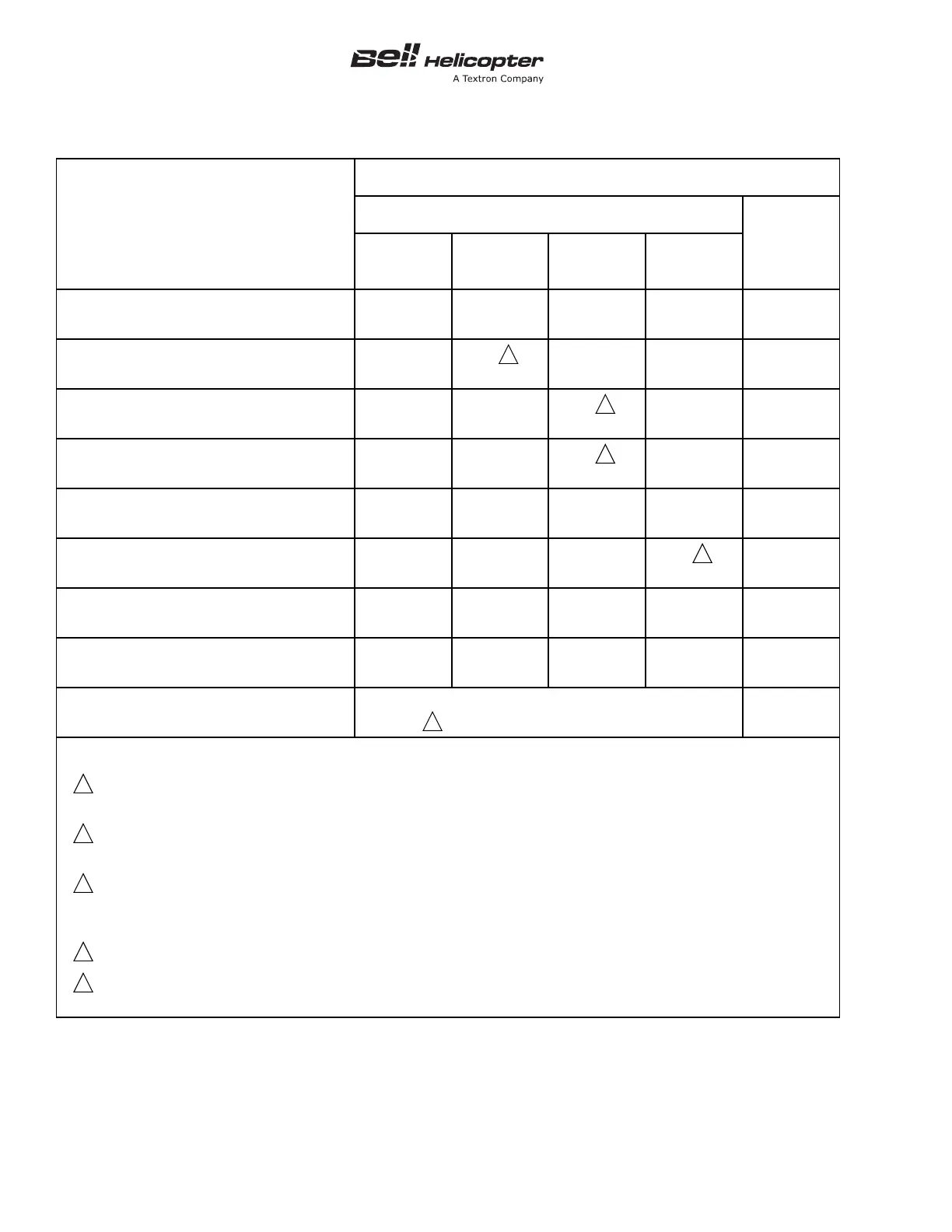

Table 5-4. Special Inspections

COMPONENT

INSPECTION SCHEDULE

HOURS AFTER INITIAL INSTALLATION

INITIAL

1 TO 5

HOURS

3 TO 8

HOURS

10 TO 25

HOURS

100 ±10

HOURS

Main Rotor Hub Mast Nut Torque Check

(paragraph 5-47)

X

Pillow Block Retention Bolts Torque

Check (paragraph 5-48)

X

Tail Rotor Gearbox Torque Check

(paragraph 5-49)

X

Swashplate Tilt Friction (paragraph

5-49)

X

Disc Pack Coupling Torque Check

(paragraph 5-49)

X

Power Plant Torque Check (paragraph

5-50)

X

Tailboom Attachment Torque Check

(paragraph 5-50)

X

Transmission Top Case Torque Check

(paragraph 5-50)

X

Fuel System (paragraph 5-46) Immediately after maintenance or component

change

NOTES:

Retouch corrosion preventive compound and anti-slippage marks as required after torque check.

Repeat torque check every 100 flight hours.

Torque check must be repeated every 10 to 25 hours until the torque is stabilized. After torque has

stabilized, repeat torque check every 300 flight hours.

If fastener is improperly torqued:

• Inspect nuts and bolt threads, and shank for damage.

• Inspect engine mounts and supporting structure for damage.

Repeat the swashplate tilt friction check every 300 flight hours.

Complete fuel system operational check immediately after fuel system maintenance or component

change (paragraph 5-46).

Loading...

Loading...