McCAULEYPROPELLERSYSTEMS

CONSTANTSPEEDCOMPOSITEOWNER/OPERATOR

INFORMATIONMANUAL

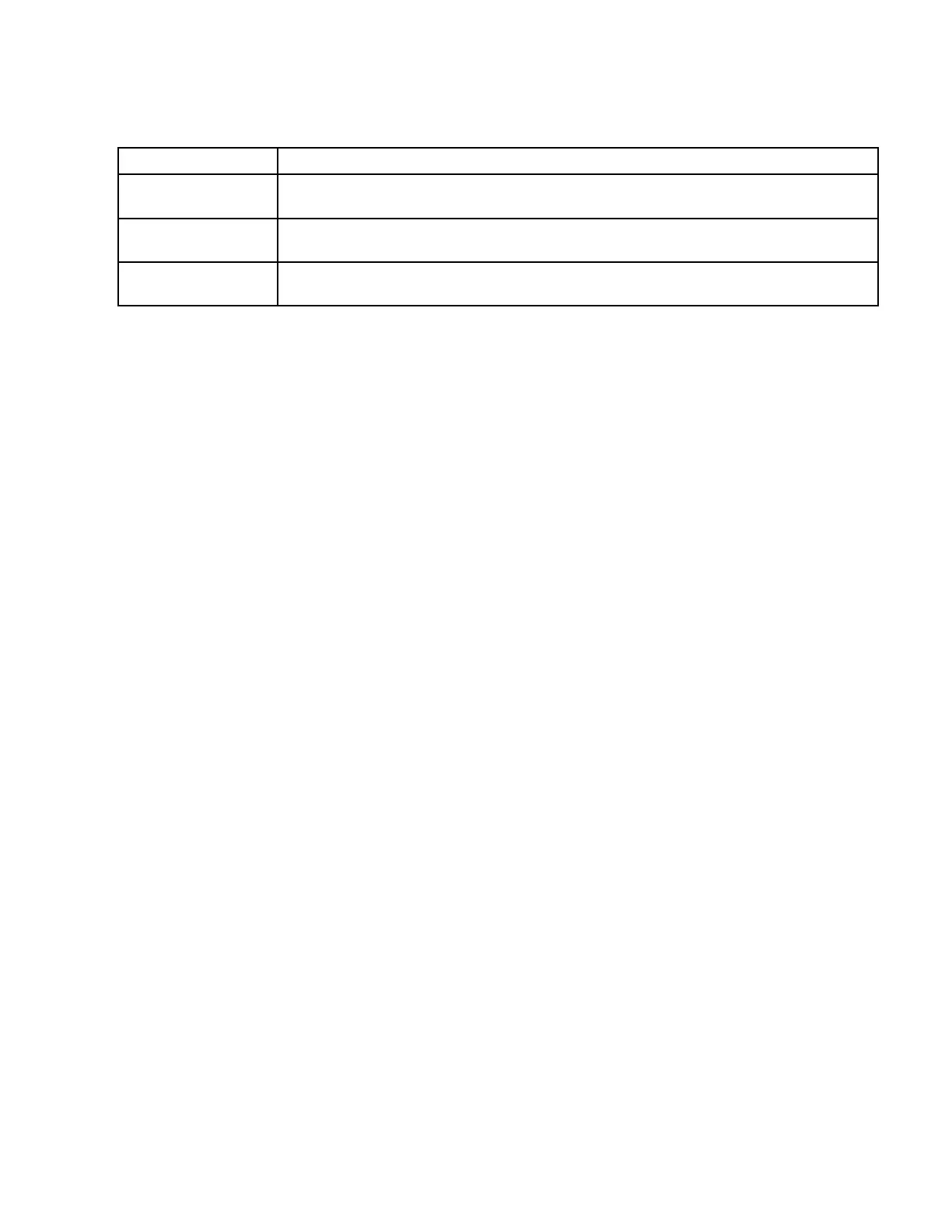

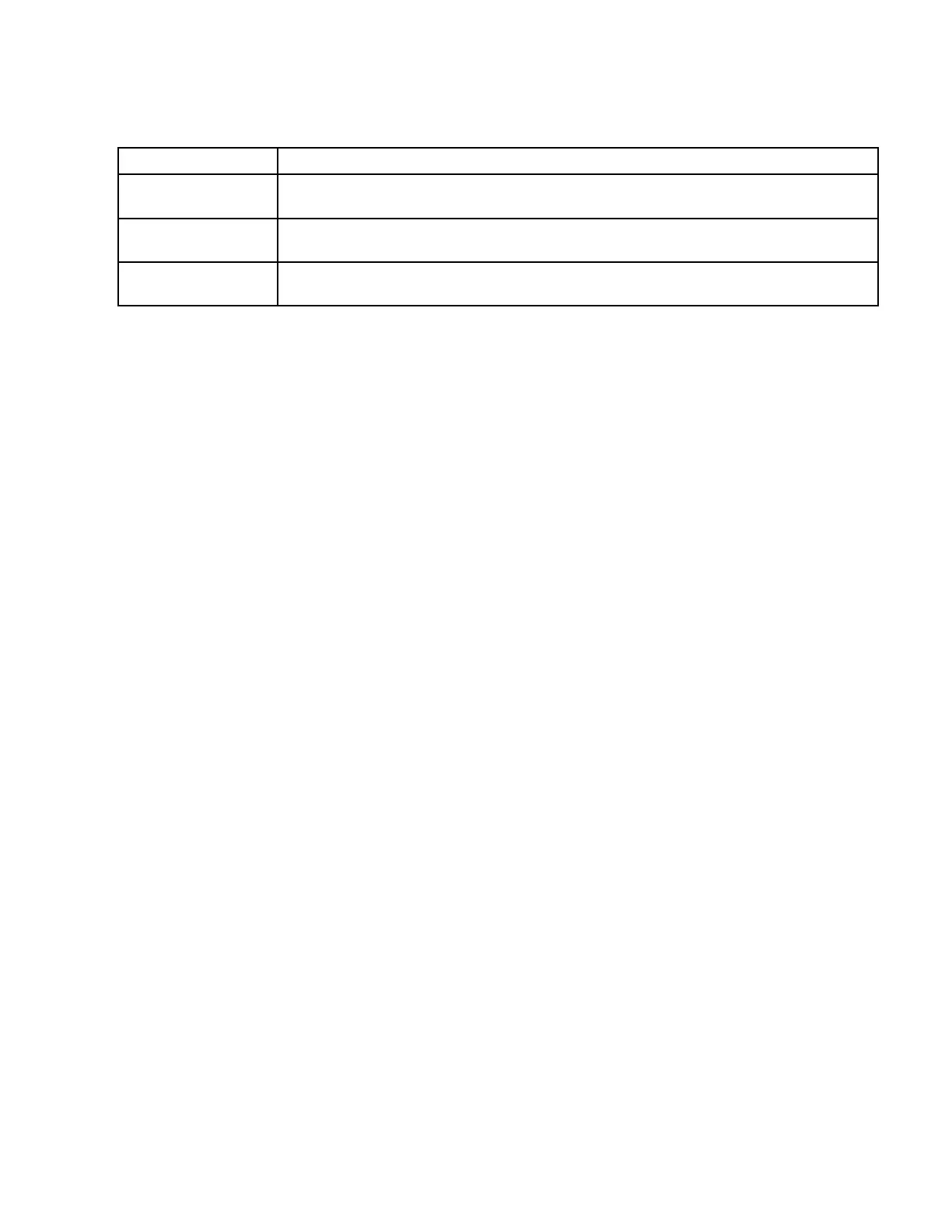

Table707.PaintandPrimerMixtures(continued)

Paint/Primer

MixtureInstructions

Semi-FlatGrayPaint

F63YXA11582

MixasdirectedbythemanufacturerwithV66V27catalystandR7K84reducer(Note1)

GlossYellowPaint

F63BXY11719

MixasdirectedbythemanufacturerwithV66V27catalystandR7K84reducer(Note1)

Semi-FlatRedPaint

F63TXR11347

MixasdirectedbythemanufacturerwithV66V27catalystandR7K84reducer(Note

1)FederalStandard595Color31136

NOTE1:ThecolornumbersareassignedbytheAtlanta,GeorgiaSherwin-Williamsfacility.

B.Thepaintedsurfacemustberecoatedwiththerstcoatofthenishenamelwithinfourhoursof

applicationoftheprimer.

C.Applythepaintinaccordancewiththemanufacturer'sinstructions.

NOTE:Overnightdryingtimeisrecommendedafterpaintapplication.

D.Therecommendeddrylmpaintthicknessonconstantspeedpropellerbladesshouldbe3milsthick.

NOTE:Tipstripesshouldbepaintedonthecambersideonlysoasnottointerferewiththepilot's

eldofvision.Somepropellersinstalledinapusherconguration(andoutofthepilot's

eldofview)mayhaveadifferentpaintschemeforthepropellerbladetips.

7.SpinnerChromePlating

A.McCauleydoesnotapprovethechromeplatingofMcCauleypropellerspinners.Fieldexperiencehas

shownthatchromeplatedspinnersoftenpeelafterashorttimeinservice.Strongevidencealsoexists

thatchromeplatingcanleadtospinnerfatiguecracking,thusscrappingthespinnershell.Chrome

platingwillvoidtheMcCauleywarranty.

61-03-00Page710

©McCauleyPropellerSystemsApr11/2014

Loading...

Loading...