Engine Maintenance

90

3. Reinstall the bleeder set screw or reinstall the

thermostat and housing.

4. On units with TK376 engines and tube and fin

radiator coils only: Continue slowly pour the

coolant into the system until you see coolant

coming out of the petcock (bleed tap) on the

radiator header. Then close the petcock.

5. Fill the coolant expansion tank to the full

mark. Then fill the overflow portion of the

tank to the full cold level.

6. Make sure that the amount of coolant that

goes back into the system is approximately

equal to the amount of coolant that came out

of the system.

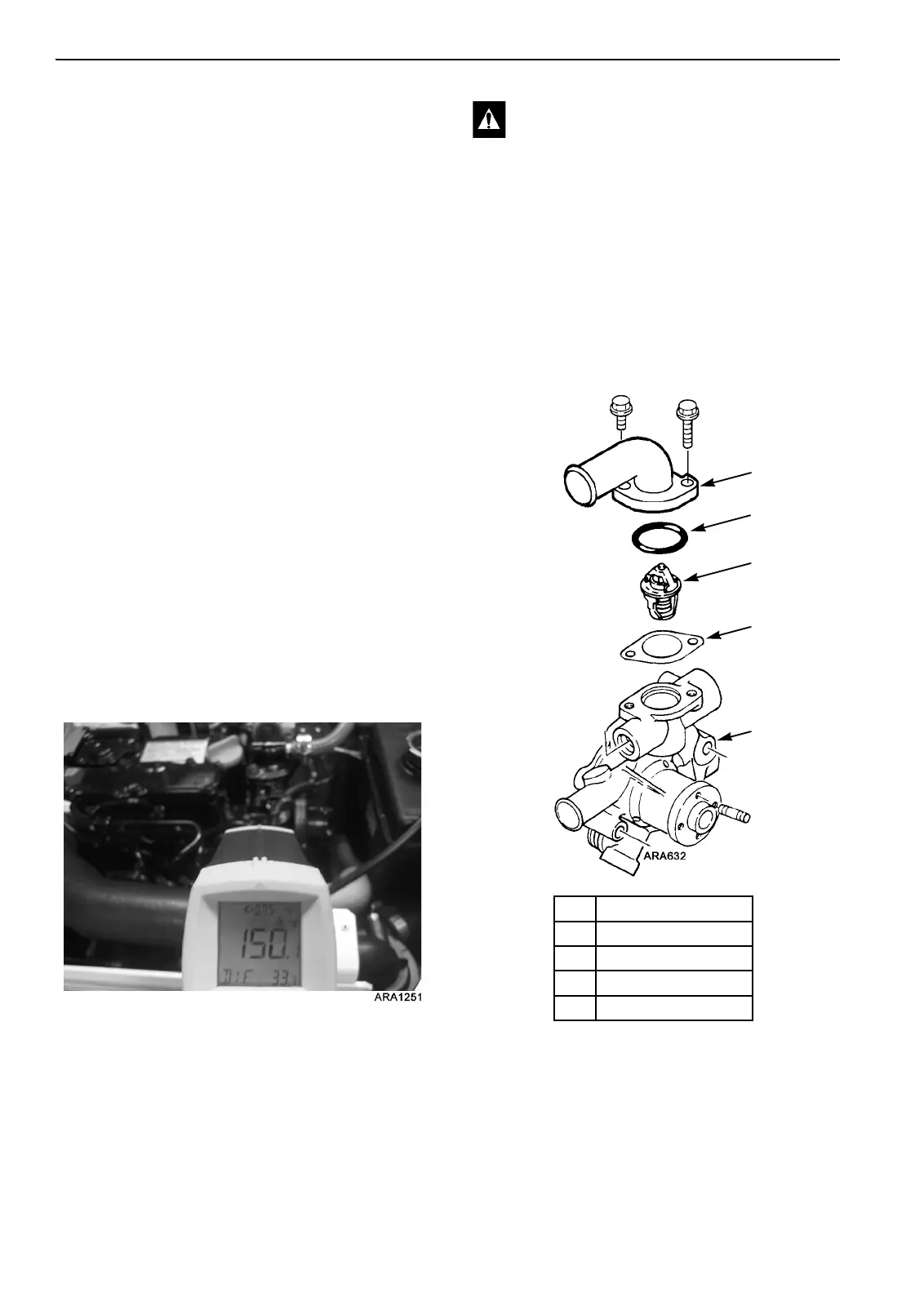

7. Run the unit in low speed while watching the

unit engine temperature gauge or use a

non-contact thermometer pointed at the water

pump bleeder bolt located on the curbside of

the water pump below the thermostat.

8. When the temperature reaches 150 F (66 C)

for units with 160 F (71 C) thermostats, or

170 F (76 C) for units with 180 F (82 C)

thermostats, shut off the engine for 2 minutes

to allow the thermostat to heat soak and open

completely to purge air out of block, head, and

water pump.

Figure 165: Checking Temperature

9. After 2 minutes, re-start the engine and run it

in low speed while filling the expansion tank

to the full mark. Install the expansion tank cap

fully seated and run the unit for approximately

15 minutes. Shut off the engine and re-check

the coolant level after the unit cools down for

15 minutes.

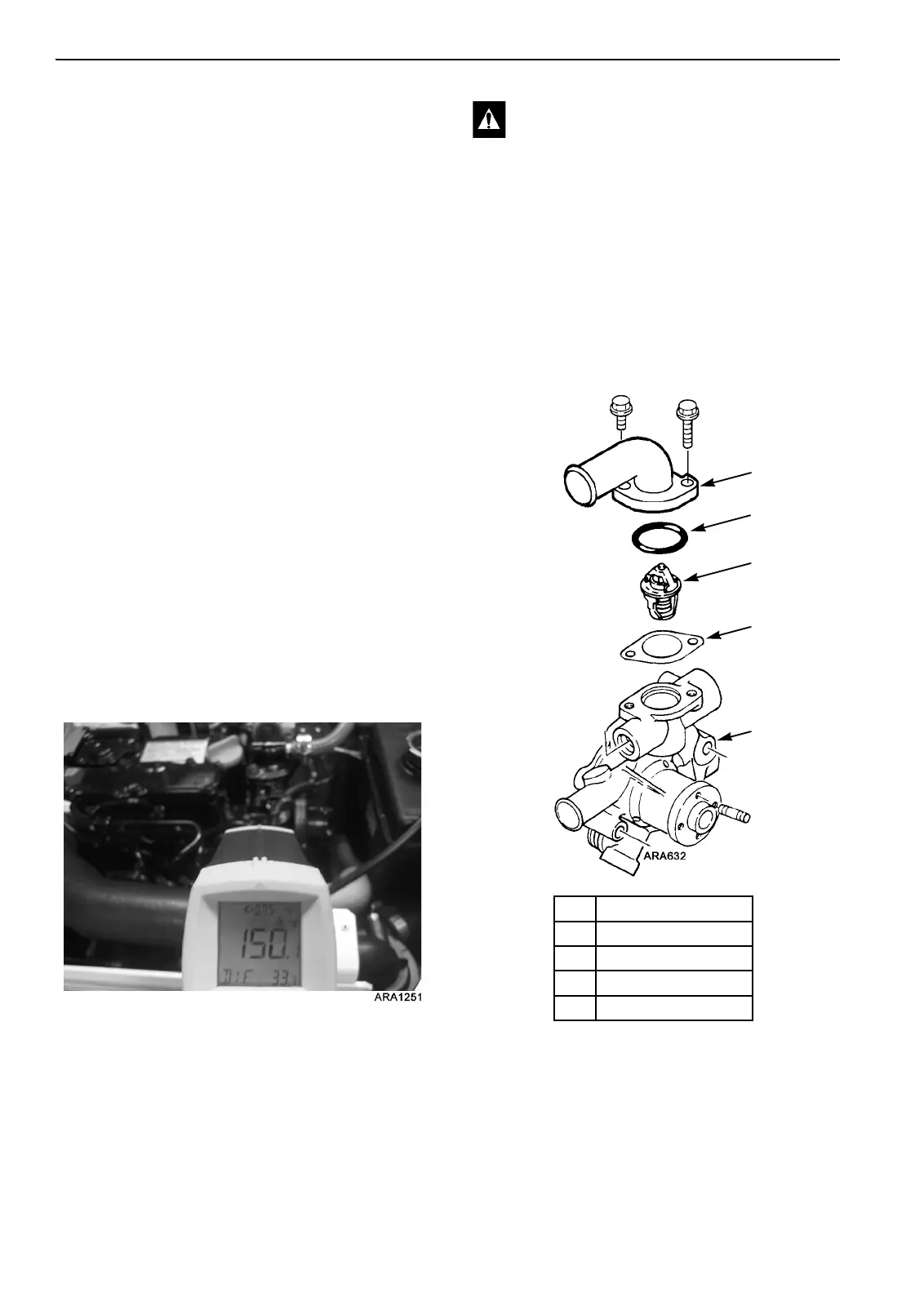

Engine Thermostat

For the best engine operation, use a 160 F (71 C)

thermostat year round.

WARNING: Failure to follow this

procedure can result in engine damage.

Air trapped in the engine block and head

can create localized hot spots that can

cause permanent damage. Air can also

cause the thermostat and engine safety

shutdown feature to malfunction, causing

further engine damage.

1. Thermostat Housing

2. Gasket

3. Thermostat

4. Gasket

5. Water Pump

Figure 166: Water Pump Assembly and Thermostat

Loading...

Loading...