Clutch Maintenance

62

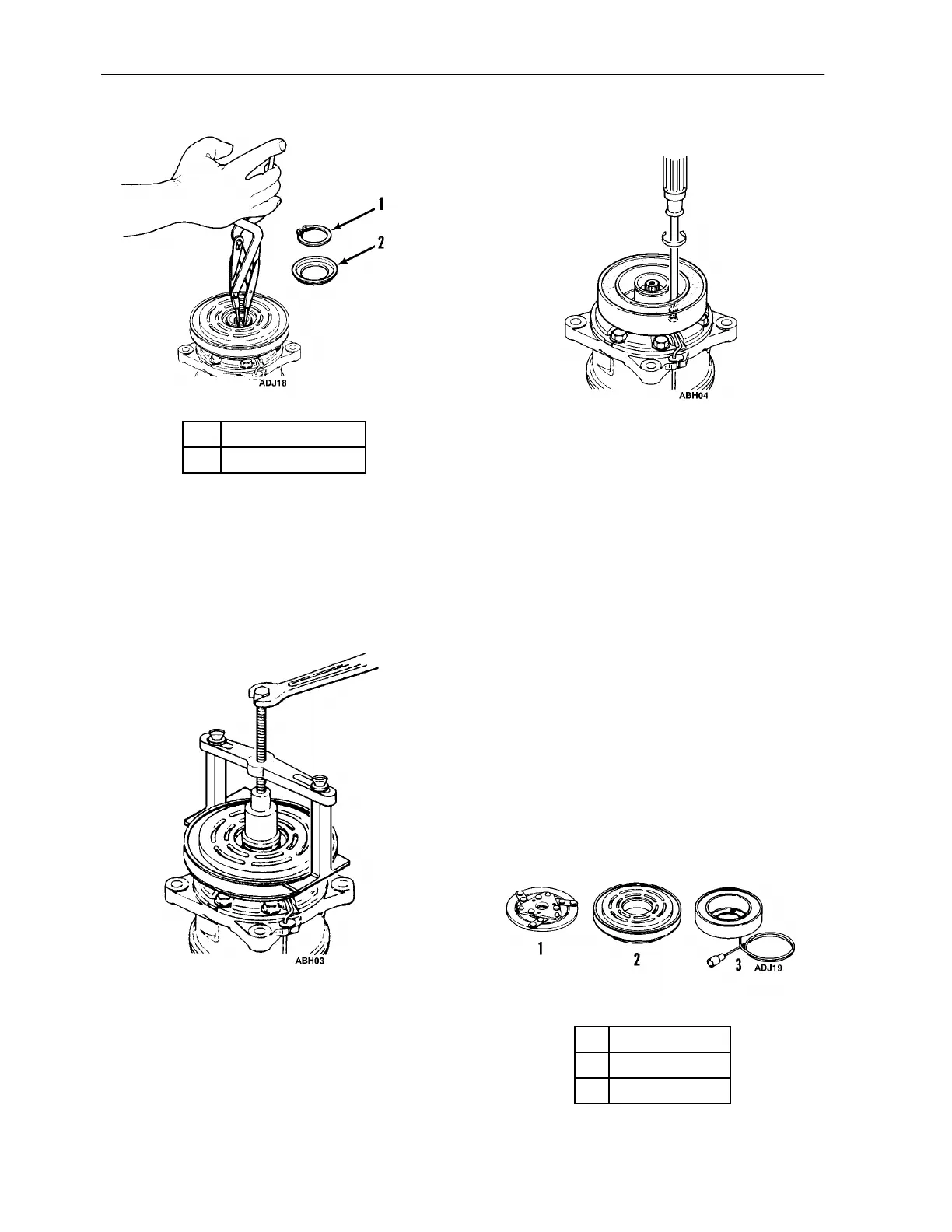

Figure 42: Remove Snap Ring and Cover

5. Remove the pulley assembly using the clutch

remover (P/N 204-806) and the spacer

positioned on the cylinder head hub.

NOTE: To avoid damaging the pulley

groove, the pulley claws should be hooked

into (NOT UNDER) the pulley groove.

Figure 43: Remove Pulley

6. Remove the coil’s lead wire from the holder

on the top of the compressor.

7. Remove the three screws that attach the coil to

the compressor and remove the coil.

NOTE: DO NOT hold the coil by the lead

wire.

Figure 44: Remove Coil

Inspection

1. Drive Plate

If the contact surface is scorched, the drive

plate and pulley should be replaced.

2. Pulley Assembly

Inspect the appearance of the pulley assembly.

If the pulley’s contact surface is excessively

grooved due to slippage, both the pulley and

drive plate must be replaced. There should

also be no foreign matter, such as oil or grit,

lodged between the clutch plate and pulley.

Thoroughly clean these contact surfaces and

the drive plate.

3. Coil

Inspect the coil for a loose connector or

cracked insulation. If the insulation is cracked,

replace the coil. If the field coil lead wire is

broken, replace the field coil.

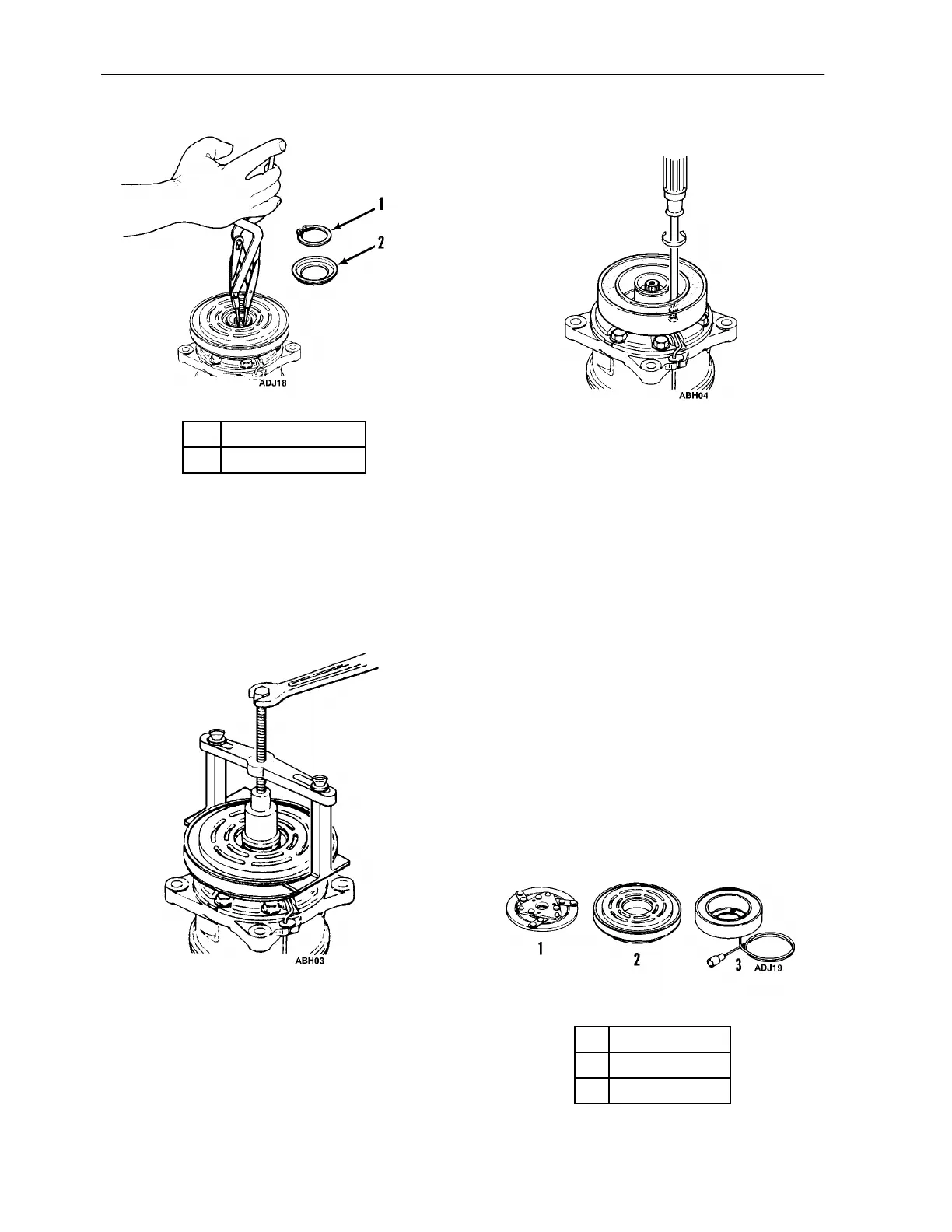

Figure 45: Inspect Components

1. Snap Ring

2. Cover

1. Drive Plate

2. Pulley Assembly

3. Coil

Loading...

Loading...