Do you have a question about the Thermo Scientific thermoscientific Vanquish Pumps C and is the answer not in the manual?

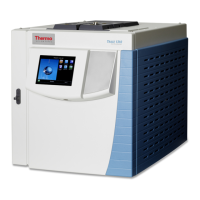

| Brand | Thermo Scientific |

|---|---|

| Model | thermoscientific Vanquish Pumps C |

| Category | Laboratory Equipment |

| Language | English |

Information for ordering HPLC products and sales support from local sales organizations.

Information for contacting local support organizations for technical assistance on HPLC products.

Describes functional features, operating principles, installation, setup, and troubleshooting of the Vanquish device.

Details typographical conventions, safety messages, and special notices used throughout the manual.

Lists additional hardware and software documentation available for reference.

Explains safety symbols, signal words, and notices used to prevent injury and device damage.

Defines the device's purpose as part of the Vanquish system for analyzing compounds in sample solutions.

Provides general safety information, including operating within specifications and using authorized parts.

Provides recommendations on using compatible solvents and additives to protect system functionality.

Details the device's compliance with various regulatory standards, including CE, RoHS, and FCC.

Highlights key features of the Vanquish pump, including dual-piston design and seal wash system.

Explains the serial dual-piston pump operation with compressibility compensation for pulse-free flow.

Locates user-accessible components behind the front doors for easy access and maintenance.

Details the active system for keeping pistons wet and rinsing seals, prolonging component lifetime.

Describes the unit comprising the purge valve and the system pressure sensor for system control.

Explains the system comprising capillary and static mixers for improving baseline smoothness.

Describes the leak sensor system that monitors for liquid leaks and alerts the user.

Covers device operation primarily via computer with Chromeleon software and an internal keypad.

Provides instructions for inspecting packaging, handling the heavy device safely, and required tools.

Lists the items included in the delivery, such as the pump, ship kit, manual, and power cord.

Details safety guidelines, including handling heavy loads and electrical safety precautions during installation.

Outlines the steps for hardware setup, flow connections, powering on, and software configuration.

Specifies important environmental requirements for optimal device performance, including laboratory conditions.

Explains how to open front doors to access user-serviceable components and flow connections.

Guides on setting up hardware, including system arrangement and connecting devices and cables.

Provides rules and recommendations for setting up flow connections and additional flow connections.

Details the setup procedure for the seal wash system, including interconnecting modules and filling the reservoir.

Explains how to connect the pump to the autosampler using capillaries and guide holes.

Describes the procedure for powering on the device, including self-test and seal wash cycle initiation.

Guides on configuring the Vanquish system within the chromatography software and its associated help.

Assumes initial setup is complete and refers to installation for setup steps and Chromeleon Help for details.

Covers safety aspects during operation, including LED luminosity warnings and system pressure limit settings.

Details the device's control elements, including keypad, status indicators, and their functions.

Explains the use of the main power switch and system power button for controlling device power.

Provides guidelines for using solvents and additives to prevent system contamination and ensure optimal performance.

Outlines additional steps for first-time operation and starting sample analysis, including system equilibration.

Describes key parameters for routine operation, including flow, pressure, solvent composition, and waste liquid monitoring.

Explains the process of rinsing the pump with solvents, covering settings and automatic/manual procedures.

Offers tips for maximizing device performance, including component monitoring and solvent line shut-off valves.

Provides instructions for short-term and long-term shutdown procedures, including detector-specific steps.

Describes routine maintenance and service procedures, emphasizing user-serviceable parts and authorized personnel.

Details safety guidelines for maintenance, including high voltage, hazardous substances, and solvent spraying precautions.

Outlines rules for successful maintenance, emphasizing authorized parts, tool usage, and component cleanliness.

Provides a maintenance plan with suggested frequencies for daily and regular checks and tasks.

Explains procedures for flushing the pump to avoid contamination and address persistent contamination.

Details cleaning and decontamination procedures, requiring qualified personnel and protective equipment.

Explains software functions for estimating consumable lifetime and scheduling maintenance based on usage.

Covers maintenance procedures for the seal wash system, including leakage testing and replacing lines/detectors.

Details maintenance procedures for the pump head, including replacing parts like pistons, seals, and the head itself.

Describes procedures for replacing and cleaning inlet and outlet check valves.

Covers maintenance for mixing systems, including permeability testing and replacing static or capillary mixers.

Provides procedures for emptying, replacing solvent lines, and replacing solvent line filters.

Details the procedure for replacing the purge valve knob to resolve leakage issues.

Outlines a general test procedure to identify and locate potential leaks in the pump system.

Provides instructions for safely replacing blown main power fuses using a screwdriver.

Guides on updating device firmware via Chromeleon software, including necessary preparations and precautions.

Explains how to remove and install device doors, emphasizing care to avoid damage to hinges.

Covers preparation, transport, and shipping procedures, including safety guidelines for handling heavy devices.

Details the process of removing, returning, installing, and setting up a slide-in module.

Introduces features that help identify and eliminate problem sources, including status indicators and alarms.

Lists common messages from Chromeleon Audit Trail, their device information, and remedial actions.

Provides tests to find out if leakage is present in the pump and locate the source.

Guides on resolving liquid leaks detected by the leak sensor, including locating the source and performing tests.

Helps identify and eliminate sources of pressure problems and shifts in retention time.

Provides guidance on purging the pump against backpressure to remove persistent air bubbles.

Introduces specific information for quaternary, binary, and isocratic pumps, including components and principles.

Provides specific information on quaternary and dual pumps, including interior components and operating principles.

Offers specific information on the binary pump, covering interior components, operating principle, dwell volume, and solvent composition.

Provides specific information on the isocratic pump, detailing interior components and operating principles.

Explains how to adapt dwell volume or ripple by replacing the mixing system for different gradient requirements.

Details the process of removing the original mixing system and installing a new one with different volume.

Covers modifications for using normal-phase solvents and additives, including pump/autosampler modification and considerations.

Details performance specifications for quaternary, dual, binary, and isocratic pumps, including accuracy and pressure.

Lists the physical characteristics of the device, such as operating temperature, humidity, dimensions, and weight.

States that devices must be operated with authorized parts and that part numbers are subject to change.

Lists the items included in the ship kit for various pump models, subject to change.

Describes optional accessories available, such as solvent shut-off valves, solvent monitors, and buffer performance kits.

Lists available consumables and replacement parts, including maintenance kits for VC and VF pumps.

Provides part numbers for pump heads and associated components for VC and VF pump models.

Lists reservoirs for solvents, wash systems, and seal wash parts with their respective part numbers.

Lists part numbers for static and capillary mixers, including standard and optional mixing systems.

Lists miscellaneous parts such as capillaries, cleaning swabs, diagnostics tools, and fuses with their part numbers.

Lists part numbers for interface cables and power cords for system connectivity.

Details CE, cTUVus, RoHS, WEEE, and FCC compliance information and relevant symbols.

Explains the use of digital I/O ports for exchanging signals with external devices, including pin assignments and software configuration.