TW 230DHB

9

/ 55

OPERATING INSTRUCTIONS

C190-0101 25.07.2017 Rev: 1.0

RECOMMISSIONING AFTER STORAGE

E

nsure machine is stable.•

Remove all guards and check all fasteners. If necessary,•

retighten as described within this manual.

Ensure discharge tube is correctly fastened, free of•

objects or blockages and rotates around its pivot

without being directed to face the point of operation

(danger zone).

Ensure feed funnel is free from foreign objects e.g.•

tools and clothing.

Lower and raise feed funnel into its open and closed•

positions to confirm functionality.

Check fuel and hydraulic fluid levels within engine and•

reservoir and top up accordingly. *

Inspect all internal parts e.g. drive belts, taper locks•

and shaft keyways.

Check belt tension as described within this manual.•

Inspect cutting blades to confirm they are sharp and•

suitable for use.

Re-connect the battery to its positive and negative•

terminals.

Undertake electrical diagnostic continuity check, to•

confirm circuit is complete.

Check tyre pressures. •

Re-lubricate all grease pipes. Remove pipes and bleed•

the system prior to use, if necessary. *

Follow daily checks before starting, as described within•

this manual.

Start the machine. •

Run for 15 minutes at half throttle, prior to any cutting•

activity, to clear the combustion engine. Once

complete, bring the machine onto full throttle for a

further 5 minutes.

*Storage fluids should be replaced, DO NOT USE old

stagnate fluids.

DELIVERY

All Timberwolf TW 230DHB machines have a full pre - delivery inspection before leaving the factory and are ready to

use. Read and understand this instruction manual before attempting to operate the chipper. In particular, read pages 5-

7 which contain important health and safety information and advice.

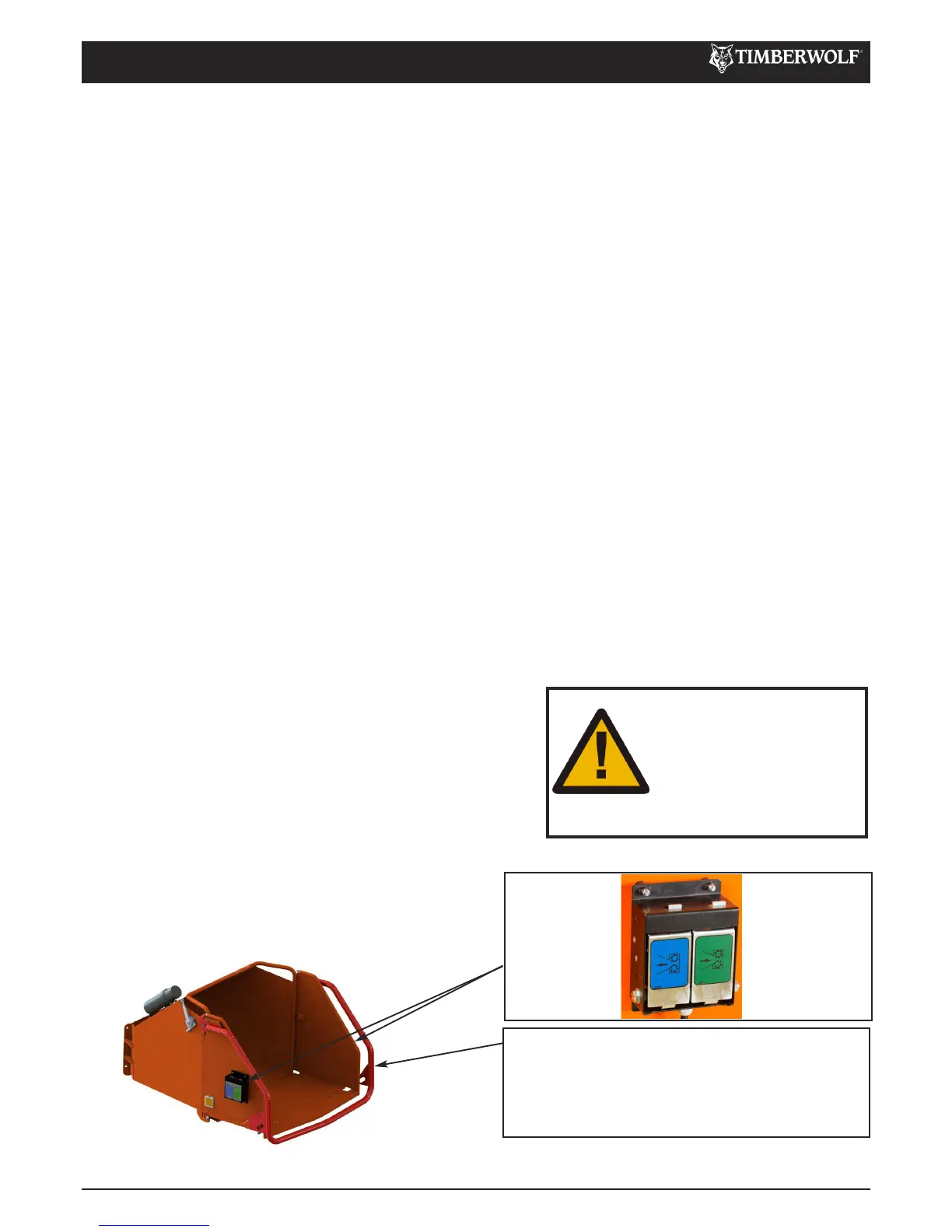

GREEN

FORWARD

FEED

CONTROL

BLUE

REVERSE

FEED

CONTROL

RED SAFETY BAR

Do not rely on the red bar to keep the roller

stationary if it is necessary to clear or touch the

roller. Always switch off the machine and remove

ignition key before approaching the roller.

There are two control boxes, located on either side of the

feed tray.

MANUAL CONTROLS

Roller control boxes: a control box is located on either side of the feed funnel. Their function is to control the feed roller

whilst processing material. They do not control the main rotor.

RED SAFETY BAR: This is the large red bar that surrounds the feed tray and side of the feed funnel. The bar is spring

loaded and connected to a switch that will interrupt the power to the rollers. The switch is designed so that it only

activates if the bar is pushed to the limit of its travel. The rollers stop instantly, but can be made to turn again by

pressing either the GREEN FEED or BLUE REVERSE controls.

Control Box Diagram

WARNING

DO NOT REMOVE, JAM,

DISABLE, BYPASS,

OVERRIDE OR OTHERWISE

IMPEDE THE

EFFECTIVENESS OF THE

RED SAFETY BAR.

Red Safety Bar Test

To ensure the safety bar is always operational it must be activated

once before each work session.

GREEN FEED CONTROL: forward feed - push the feed control once -

this activates the rollers and will allow you to start chipping (if the

rotor speed is high enough).

BLUE FEED CONTROL: reverse feed - allows you to back material out

of the rollers. The rollers will only turn in reverse as long as you

keep pressing the feed control.

Loading...

Loading...