TW 230DHB

1

2 / 55

OPERATING INSTRUCTIONS

C190-0101 25.07.2017 Rev: 1.0

BLOCKAGES

Always be aware that what you are putting into the chipper must

come out. If the chips stop coming out of the discharge tube but the

chipper is taking material in - STOP IMMEDIATELY. Continuing to feed

material into a blocked machine may cause damage and will make it

difficult to clear. If the chipper becomes blocked, proceed as follows:

Stop the engine and remove the ignition keys. •

Remove the discharge tube. Check that it is clear.•

Wearing gloves, reach into the rotor housing and scoop out the•

majority of the debris causing the blockage.

Replace the discharge tube.•

Restart the engine and increase to full speed.•

Allow machine time to clear excess chips still remaining in rotor housing before you continue feeding brushwood. Feed

in a small piece of wood while watching to make sure that it comes out of the discharge. If this does not clear it, repeat

the process and carefully inspect the discharge tube to find any obstruction.

NOTE

Continuing to feed the chipper with brushwood once it has become blocked will cause the chipper to compact the chips

in the rotor housing and it will be difficult and time consuming to clear.

AVOID THIS SITUATION ‐ WATCH THE DISCHARGE TUBE AT ALL TIMES.

W

AR

NING

D

O

NOT

R

E

A

C

H

INT

O

TH

E

ROT

OR

H

OU

SING

W

ITH

U

NP

ROTEC

TED

H

A

ND

S

.

TH

ER

E

A

R

E

SH

A

R

P

BLA

D

E

S

A

ND

A

NY

SM

A

LL

M

OV

EM

ENT

OF

TH

E

ROT

OR

M

AY

C

AU

SE

SER

IOU

S

INJU

R

Y

.

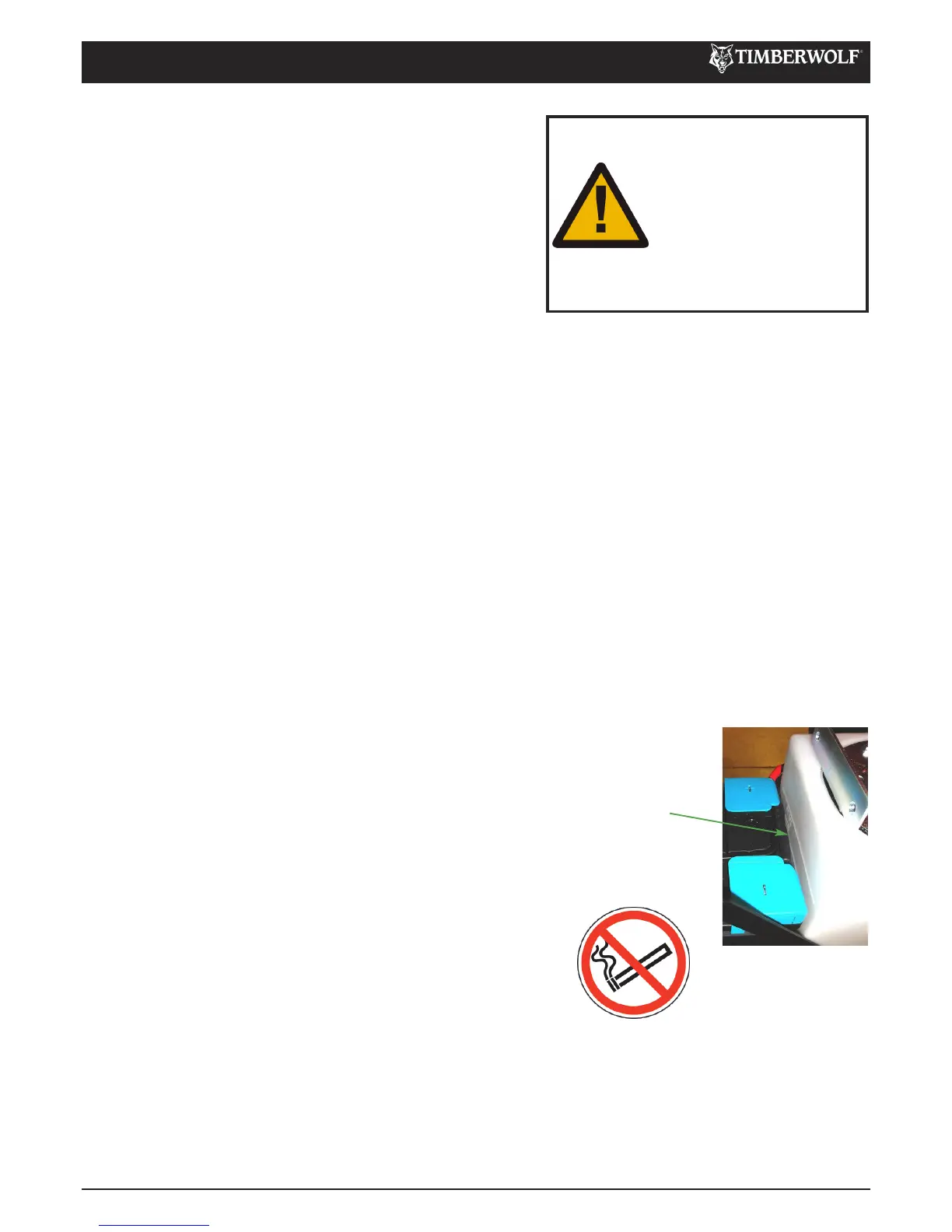

HYDRAULIC OIL LEVEL INDICATOR

The oil level will be visible through the tank wall. It should be within the upper and

lower level marks. Refer to filling and draining instructions on page 19.

BLADE WEAR

The most important part of using a wood chipper is keeping the cutter blades sharp. Timberwolf chipper blades are

hollow ground to an angle of 40 degrees. When performing daily blade checks ensure blade edge is sharp and free from

chips, if there is any evidence of damage, or the edge is “dull” change the blade(s). The TW 230DHB is fitted with 2

blades 135mm (5") long. They are 100mm wide when new. A new blade should chip for up to 25 hours before it

requires sharpening. This figure will be drastically reduced by feeding the machine with stony, sandy or muddy material.

As the blade becomes blunt, performance is reduced. With increased stress and load on the machine the chips will

become more irregular and stringy. At this point the blade should be sent to a reputable blade sharpening company.

The blade can be sharpened several times in its life. A wear mark indicates the safe limit of blade wear. Replace when

this line is exceeded.

The machine is also fitted with a static blade (anvil). It is important that the anvil is in good condition to allow the

cutting blades to function efficiently. Performance will be poor even with sharp cutter blades if the anvil is worn.

FUEL LEVEL INDICATOR

The fuel level can be seen through the wall of the plastic tank.

REFUELLING

When refuelling, follow standard Health & Safety practises:

Stop the engine and allow to cool before refuelling.•

Never smoke or allow naked flames nearby while refuelling.•

Store fuel away from vapour ignition sources such as fires and people•

smoking.

Never refuel at operating location, keep a distance of > 10 m to avoid creating fire hazards.•

Fuel storage containers must be approved for diesel fuel storage and clearly labelled with securely fitting caps. •

Clean area around fuel cap and use a funnel for refuelling. Replace the fuel cap securely. Do not fill the tank beyond•

the max. fill indicator.

Avoid skin contact with fuel. If it gets into eyes wash out with sterile water immediately and seek medical advice as•

soon as possible.

Always clean spillages quickly and change clothes before re-entering the work area if fuel is spilled onto garments.•

Loading...

Loading...