EN

31

In more detail...

EN

Care and maintenance

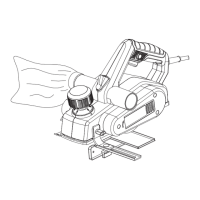

NOTE: The planning surface will end up rough and uneven unless the

blades are set properly and securely. The blades must be mounted so

that the cutting edge is absolutely level, e.g. parallel to the surface of

the back plate.

The following examples show proper and improper settings:

Fig. A – Clean smooth cut.

Fig. B – Nicks in surface – as caused by the edge of one or all blades not being

parallel to the rear base line.

Fig. C – Gouging at start – as caused by the edge of one or all blades not

protruding enough in relation to the rear base line.

Fig. D – Gouging at end – as caused by the edge of one or all blades protruding

too far in relation to the rear base line.

A

a

b

B C D

a

b

a

b

(a) = Adjustable front plate (28), (b) = Fixed back plate (25)

Cutter block

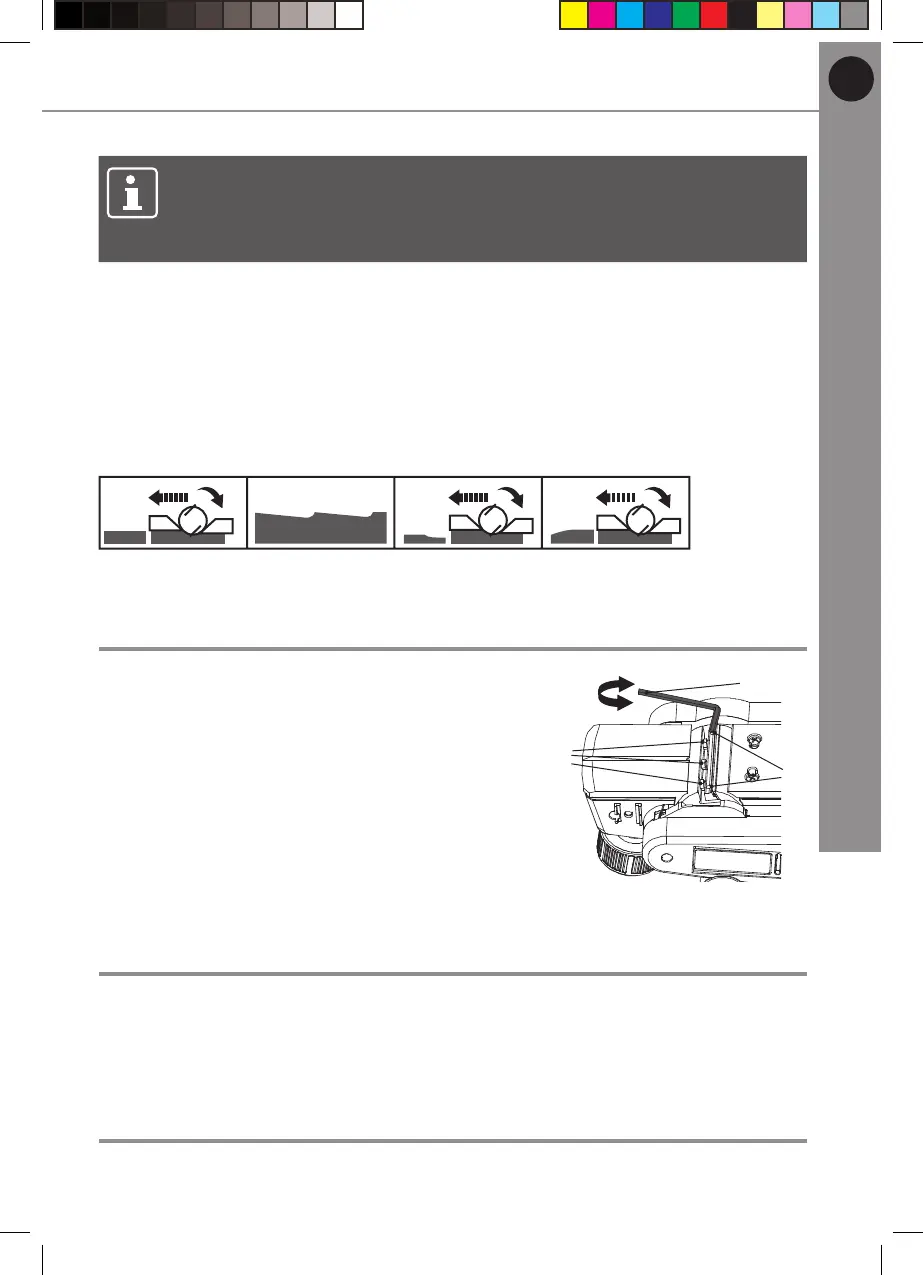

The height is pre-set in the factory and normally

there is no need to re-adjust. Nevertheless check

whether the front plate (28) runs parallel to the

roller edge occasionally. If necessary adjust the

height with the hex key (29) (Fig. 18).

1. Loosen the hex bolts (20).

2. Turn the grub screws (22) clockwise to

increase the height.

3. Turn the grub screws (22) anticlockwise to

decrease the height.

20

29

22

+

-

Fig. 18

Maintenance

Before and after each use, check the product and accessories (or attachments)

for wear and damage. If required, exchange them for new ones as described in

this instruction manual. Observe the technical requirements.

Power cord

If the supply cord is damaged, it must be replaced by a specially prepared cord

available through the service organization.

TTB876PLN by TITAN

Loading...

Loading...