Hardware Version : 5.02 Document Version : 1.0.

TECHMAN ROBOT INC. 5F., No. 58-2, Huaya 2nd Rd., Guishan Dist., Taoyuan City, 333411 , Taiwan

12

4. TM25 Maintenance Notes

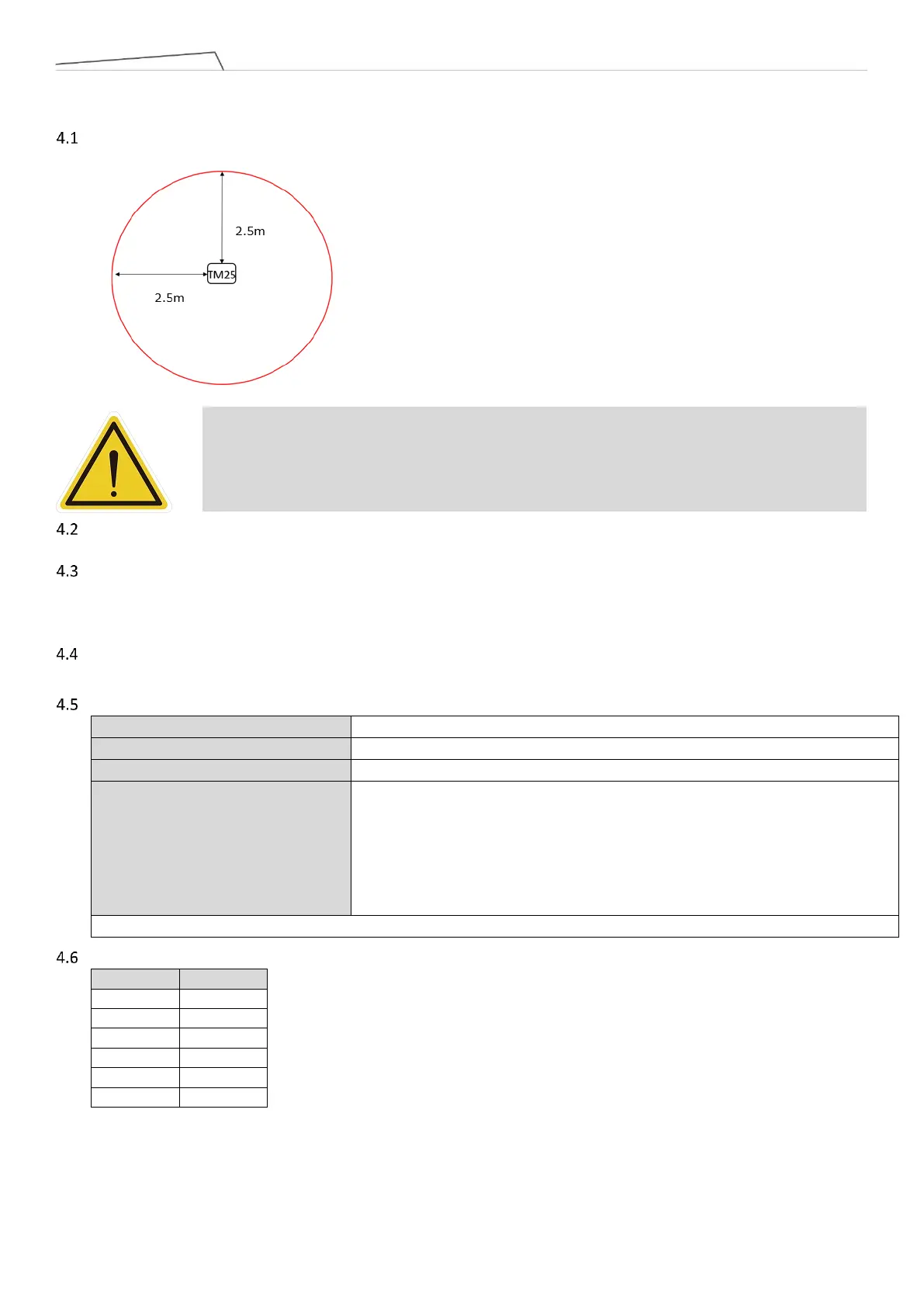

When conducting lifting or disassembly operations, it is recommended to position the robot in an spacious space.

The suggested workspace is outlined as follows:

To ensure personnel safety, wear cut-resistant and non-slip gloves, steel-toed shoes, and a safety helmet when

performing lifting or disassembly operations.

To ensure personnel safety during lifting operations, a minimum of three persons are required to work

collaboratively. One person operates the overhead crane during lifting, while the other two assist by supporting the

robot when it is away from or approaching the platform, preventing any swinging that could cause damage to

personnel or equipment.

To ensure personnel safety, the distributor should verify the stability of lifting equipment and ensure the proper

functioning of related equipment before performing lifting or disassembly operations.

Before lifting, ensure that the relevant equipment complies with the following specifications:

BS EN 1492-1 :2000+A1 :2008 Textile slings - Safety - Flat woven webbing

slings, made of man-made fibers, for general purpose use.

BS EN 1492-2 :2000+A1 :2008 Textile slings - Safety - Round slings, made of

man-made fibers, for general purpose use.

ASME B30.9-2021: Slings

JISB8818:2015 ベルトスリング

DANGER:

Use compliant tools and meet space requirements during lifting, disassembly, and

calibration. Non-compliance may cause injuries or significant damage.

Loading...

Loading...