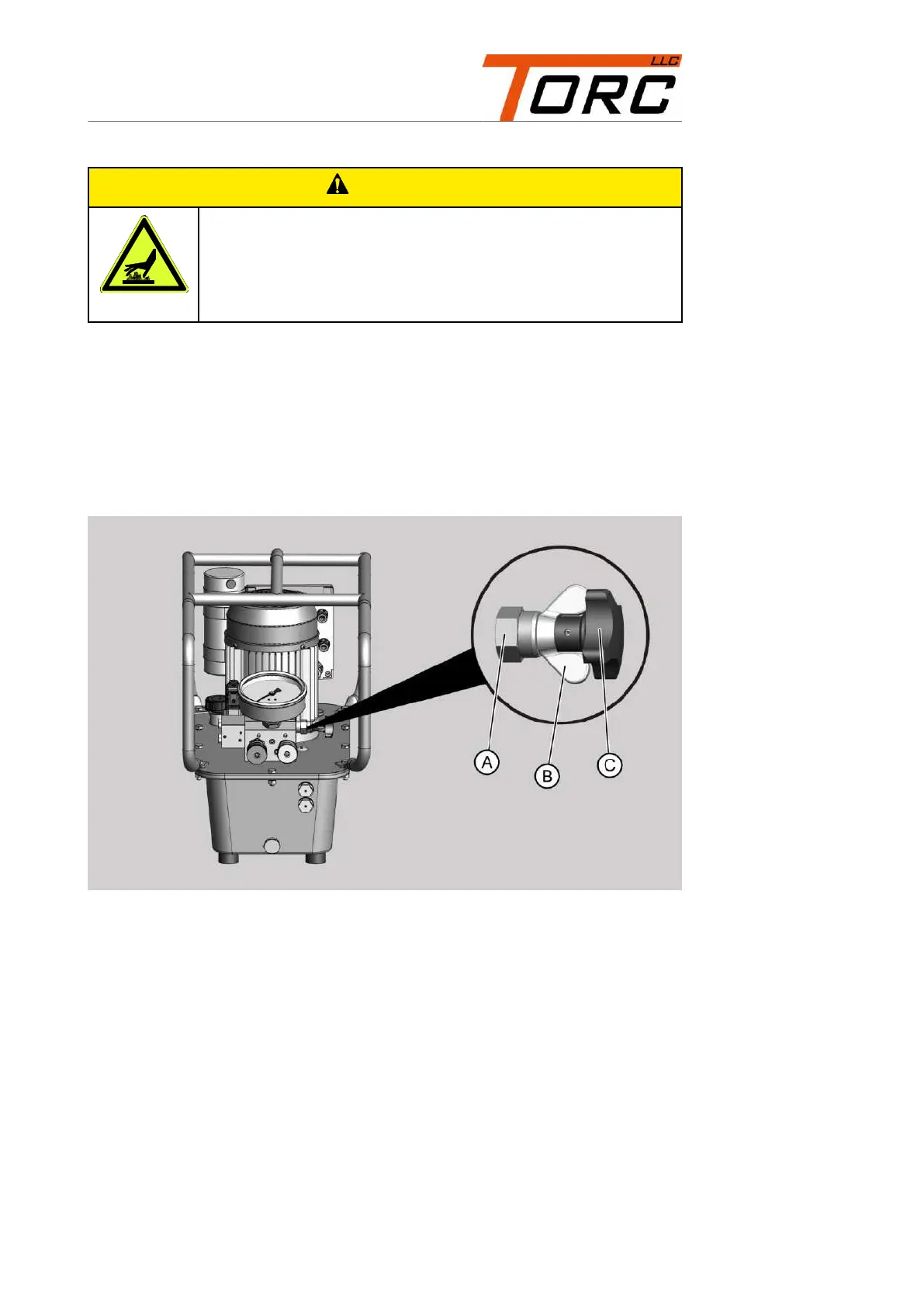

Checks and repairs on mechanical components

Replacing the torque valve

Risk of burns from hot components.

The wing nut can reach a temperature of about 60 °C during

operation.

Wear protective gloves to prevent burns when releasing

the wing nut.

To replace the torque valve, proceed as follows:

Move the unit into the repair position for the upper structures, see from

page 51.

Release the wing nut (B).

Turn the star-shaped knob (C) counter-clockwise to the stop.

Release the torque valve at the screw connection (A) with a 19 mm open-

end wrench.

Remove the defective torque valve.

Install a functioning torque valve.

Install a torque valve with a 19 mm open-end wrench.

Loading...

Loading...