11

TROUBLESHOOTING

GUIDE

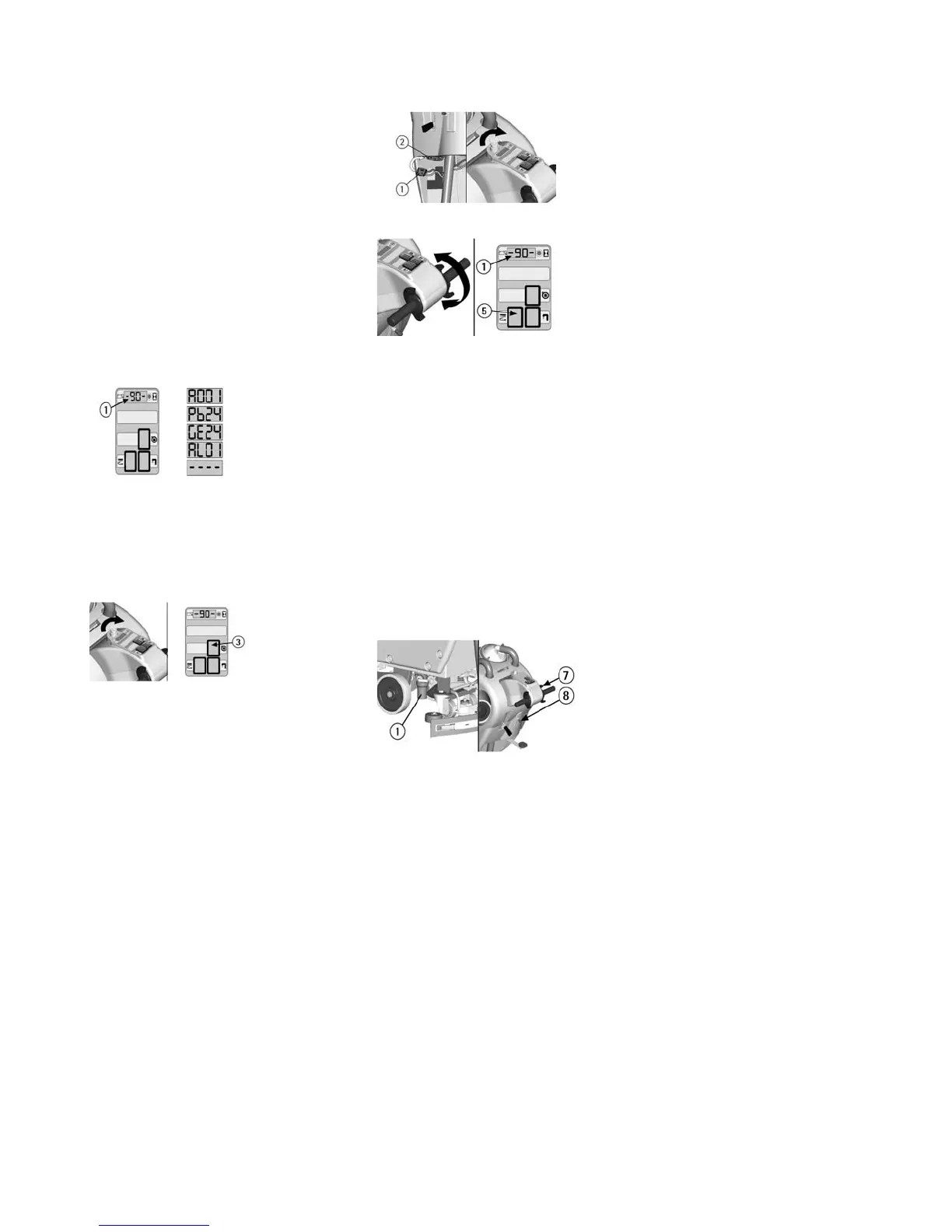

Signals on the display

A001: Indication of the version of

the electronic check card (the last

number indicates the revision of

the check card).

GE24: Indication battery check

card set for gel battery.

---- (blinking): signal indicating

the discharged battery and

intervention of the brush stop

device.

The vacuum does not

work

Verify that the switch (3) is on.

If the problem persists, please

contact an authorized technical

assistant.

The brush motor does

not work

1. Check the charge level of the

battery.

2. Check that the battery connector

(1) is correctly plugged in.

3. Verify that the switch (5) is on.

4. Activate the levers.

If the problem persists, please

contact an authorized technical

assistant.

ATTENTION:

Never leave the battery

discharged for a long time.

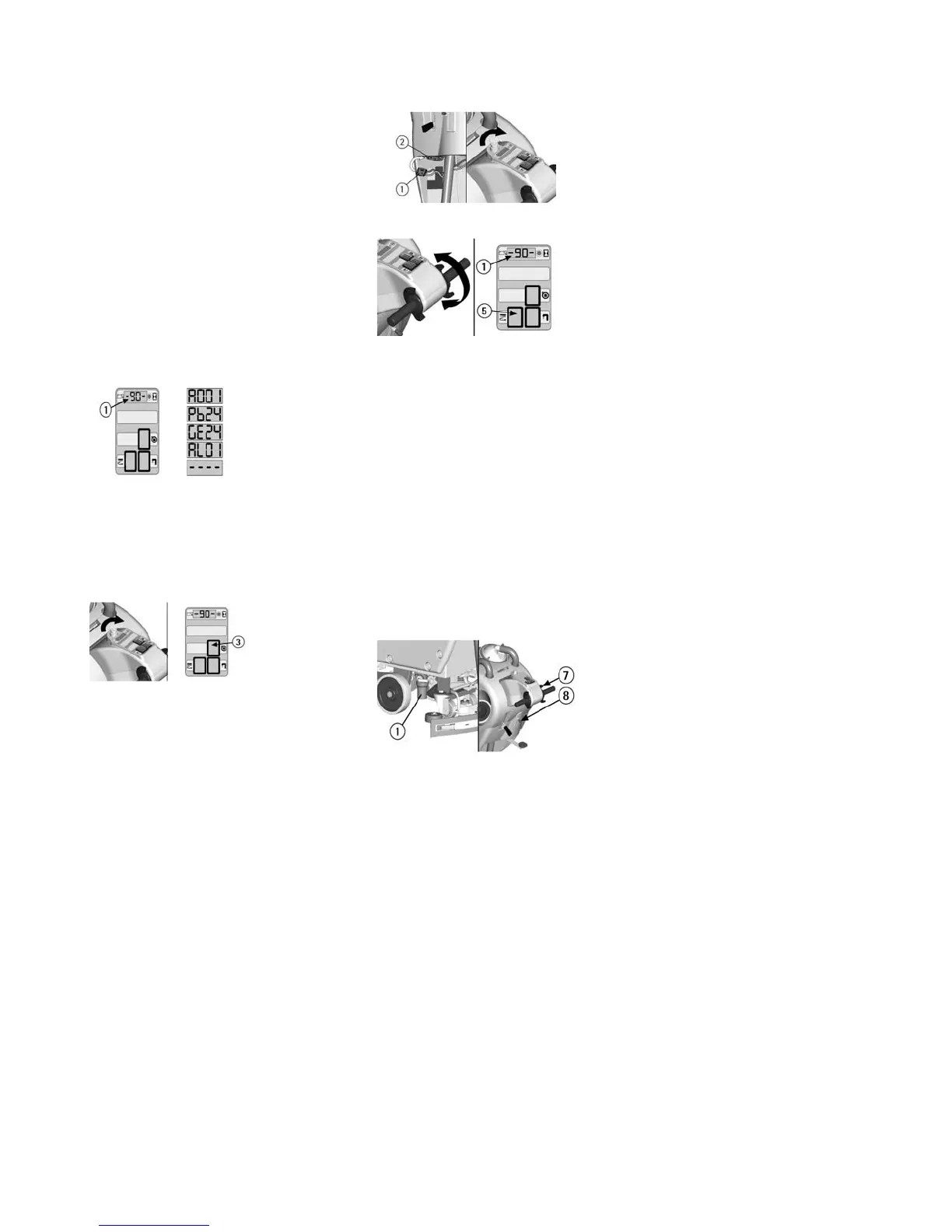

Insufficient water on the

brush

1. Check that the solution valve

lever (8) is open.

2. Check the level of the liquid in

the solution tank.

3. Check that solution filter (1) is

clean.

If the problem persists, please

contact an authorized technical

assistant.

The machine does not

clean properly

1. The brush does not have the

suitable bristle dimension: use

only original brush. For advice,

contact an authorized technical

assistant.

2. The brush bristles are worn out.

Check the brush wear condition

and eventually replace them.

To replace the brush, see

instructions at paragraph “BRUSH

DISASSEMBLY” and “BRUSH

ASSEMBLY”.

3. The solution detergent is

insufficient: open more the

solution valve.

4. Check that the liquid detergent

is in the recommended percentage.

Contact authorized technical

assistance for advice.

The squeegee does not

dry perfectly

1. Check that the squeegee rubbers

are clean.

2. Check the height and inclination

of the squeegee (see under

“SQUEEGEE” in “BEFORE

USE”).

3. Check that the suction hose is

correctly inserted in the proper seat

on the recovery tank.

4. Clean the suction filter.

5. Replace the rubbers if worn out.

6. Check that the vacuum switch is

on.

7. Check that the recovery tank is

empty.

Excessive foam

production

Check that low foam detergent has

been used. Eventually add small

quantities of anti foam liquid into

the recovery tank.

Please be aware that a bigger

quantity of foam is produced

when the floor is not very dirty.

In this case please dilute

detergent solution.

Loading...

Loading...