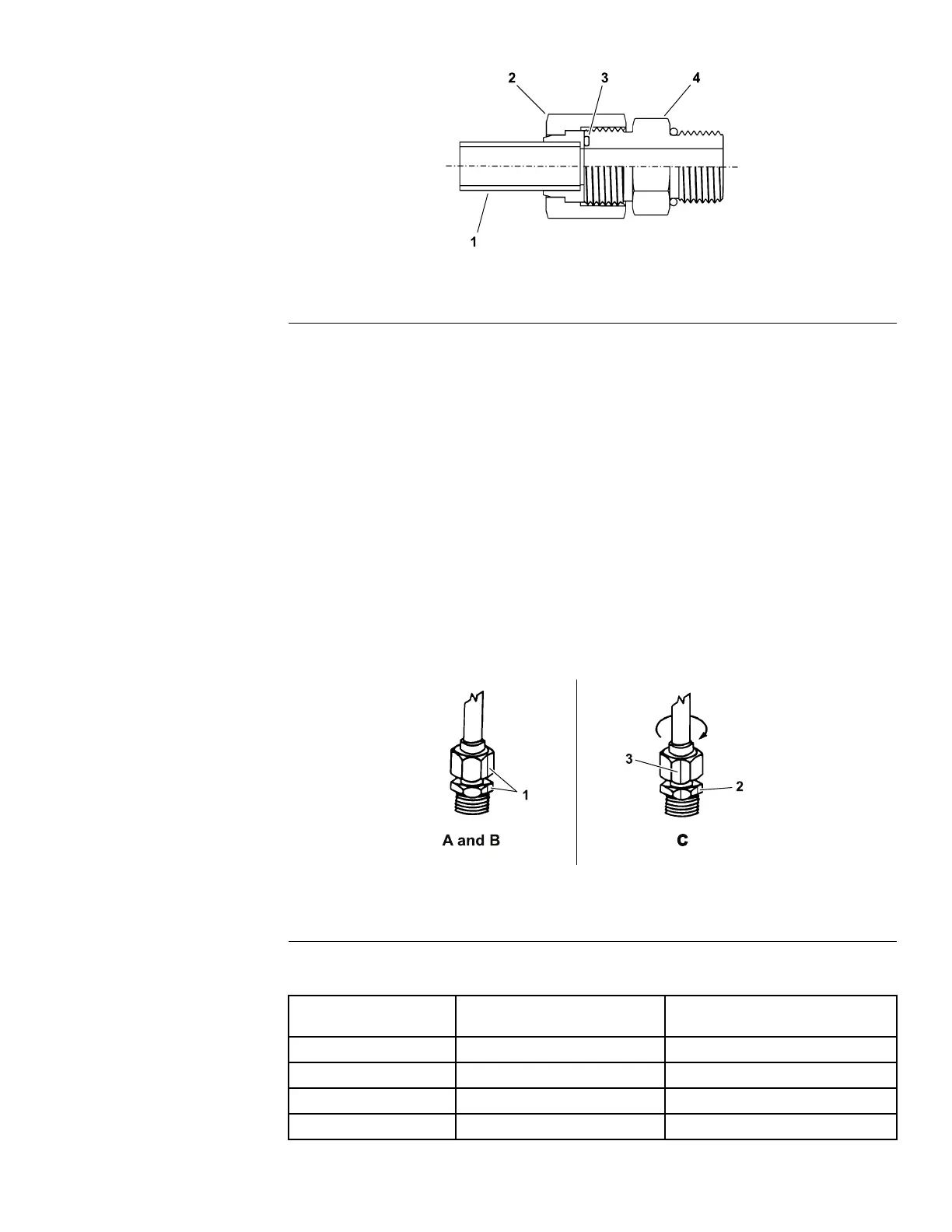

InstallingHydraulicHosesandTubes(O-RingFaceSealFitting)

g212099

Figure19

1.Tubeorhose

2.Swivelnut3.O-ring

4.Fittingbody

1.Ensurethatallthethreads,thesealingsurfacesofthehose/tube,andthe

ttingarefreeofburrs,nicks,scratches,orunwantedmaterial.

2.Tohelppreventahydraulicleak,replacethefacesealO-ringwhenyouopen

theconnection.EnsurethattheO-ringisinstalledandcorrectlyseatedinthe

grooveofthetting.LightlylubricatetheO-ringwithcleanhydraulicuid.

3.Alignthehose/tubeagainstthebodyofthettingsothattheatfaceofthe

hose/tubesleevefullytouchestheO-ringinthetting(Figure19).

4.Useyourhandtothreadtheswivelnutontothetting.Whileyouholdthe

hose/tubeinalignmentwithawrench,useatorquewrenchtotightenthe

swivelnuttotherecommendedtorquevaluewithinthespeciedrangeof

torquevalues;refertotheHose/TubeInstallationTorqueTable(page5–7).

Thisproceduretotightentheswivelnutrequiresadrive-adapterwrench

(e.g.,crowfootwrench).

Note:Itmaybenecessarytouseadrive-adapterwrench(e.g.,crowfoot

wrench)toinstallahydraulictting;refertoCalculatingtheT orqueValues

WhenUsingaDrive-AdapterWrench(page2–6).

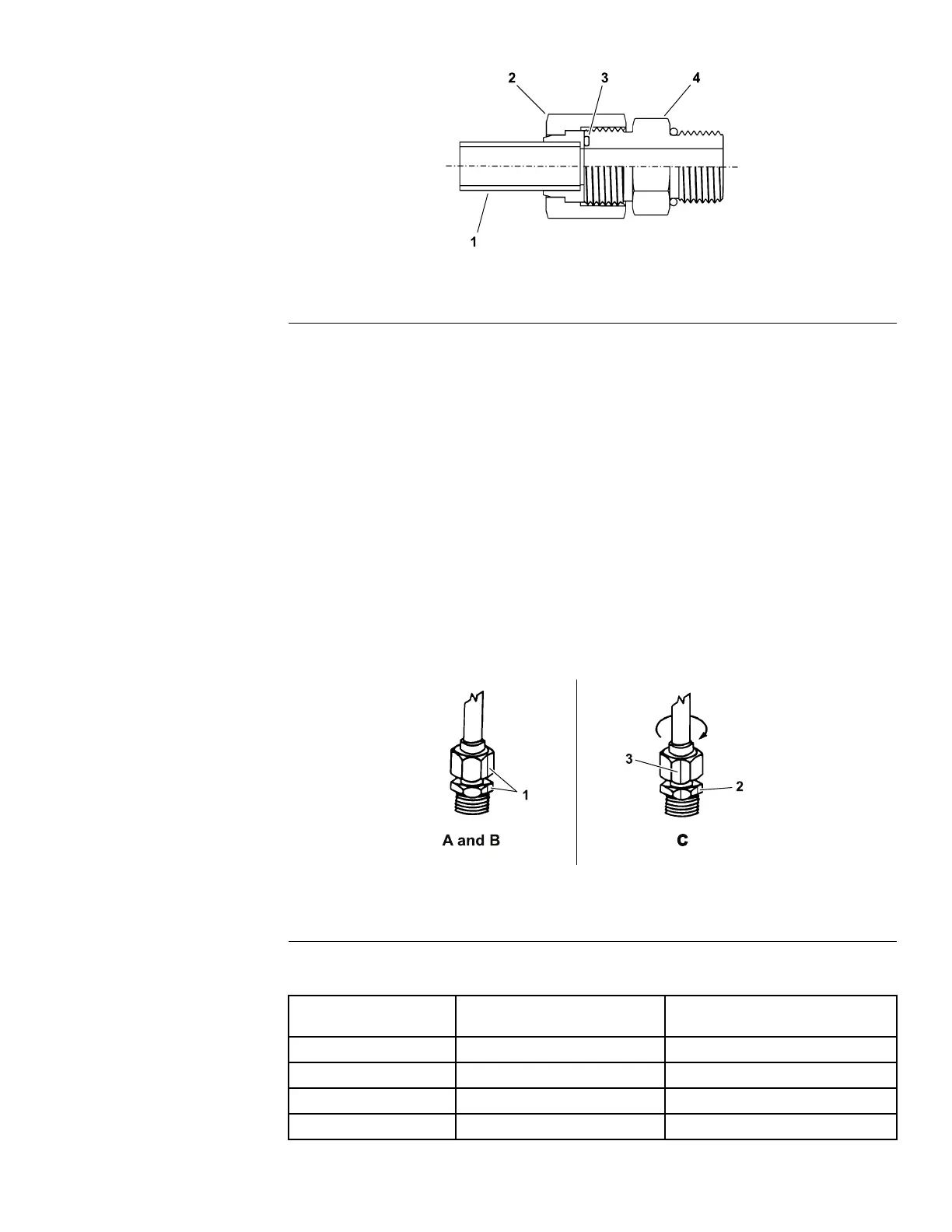

g212098

Figure20

1.Marknutandttingbody

2.Initialposition3.Finalposition

Hose/TubeInstallationTorqueTable

FittingDashSize

Hose/TubeSideThreadSize

(inch)—threadsperinch)

InstallationTorque

4

9/16—1825to29N∙m(18to22ft-lb)

6

11/16—1637to44N∙m(27to33ft-lb)

8

13/16—1651to63N∙m(37to47ft-lb)

101—14

82to100N∙m(60to74ft-lb)

SandPro

®

3040and5040

Page5–7

HydraulicSystem:GeneralInformation

20251SLRevA

Loading...

Loading...