insidethewheels,thenllthisareaoneachsideof

eachwheelwithgrease.

11.Installthelargewashersonthewheelsoverthe

grease.

12.Installtheinnertensionwheelandsecureitwiththe

nutremovedpreviously(Figure43).

13.Torquethenutto300ft-lb(407N-m).

14.Installthenewtrack,ensuringthatthelugsinthe

tracktbetweenthecogsinthemiddleofthedrive

sprocket(Figure43).

15.Installtheoutertensionwheelandsecureitwiththe

nutremovedpreviously(Figure43).

16.Torquethenutto300ft-lb(407N-m).

17.Turnthetensioningscrewcounter-clockwiseuntil

thedistancebetweenthetensionnutandthebackof

thetensiontube(Figure40)is2-3/4inches(7cm).

18.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththe

lockingboltandnut.

19.Repeatsteps2through18toreplacetheothertrack.

20.Lowerthetractionunittotheground.

MaintainingtheRoadWheels

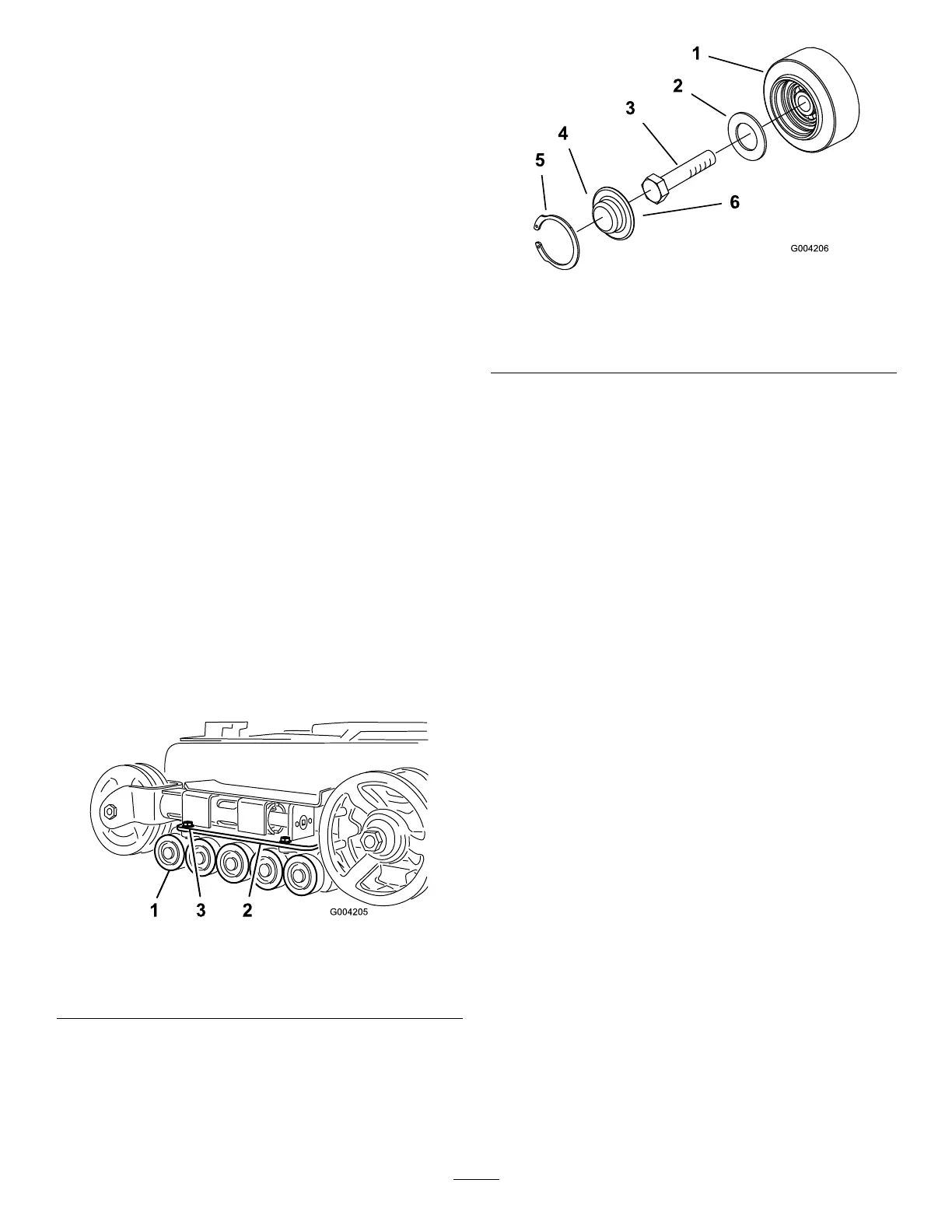

1.Removethetracks;refertoReplacingtheTracks.

2.Removethe4boltssecuringeachlowertrackguide

whichcontainstheroadwheels,andremovethem

(Figure44).

Figure44

1.Roadwheels

3.Trackguidebolts(onlytwo

shown)

2.Lowertrackguide

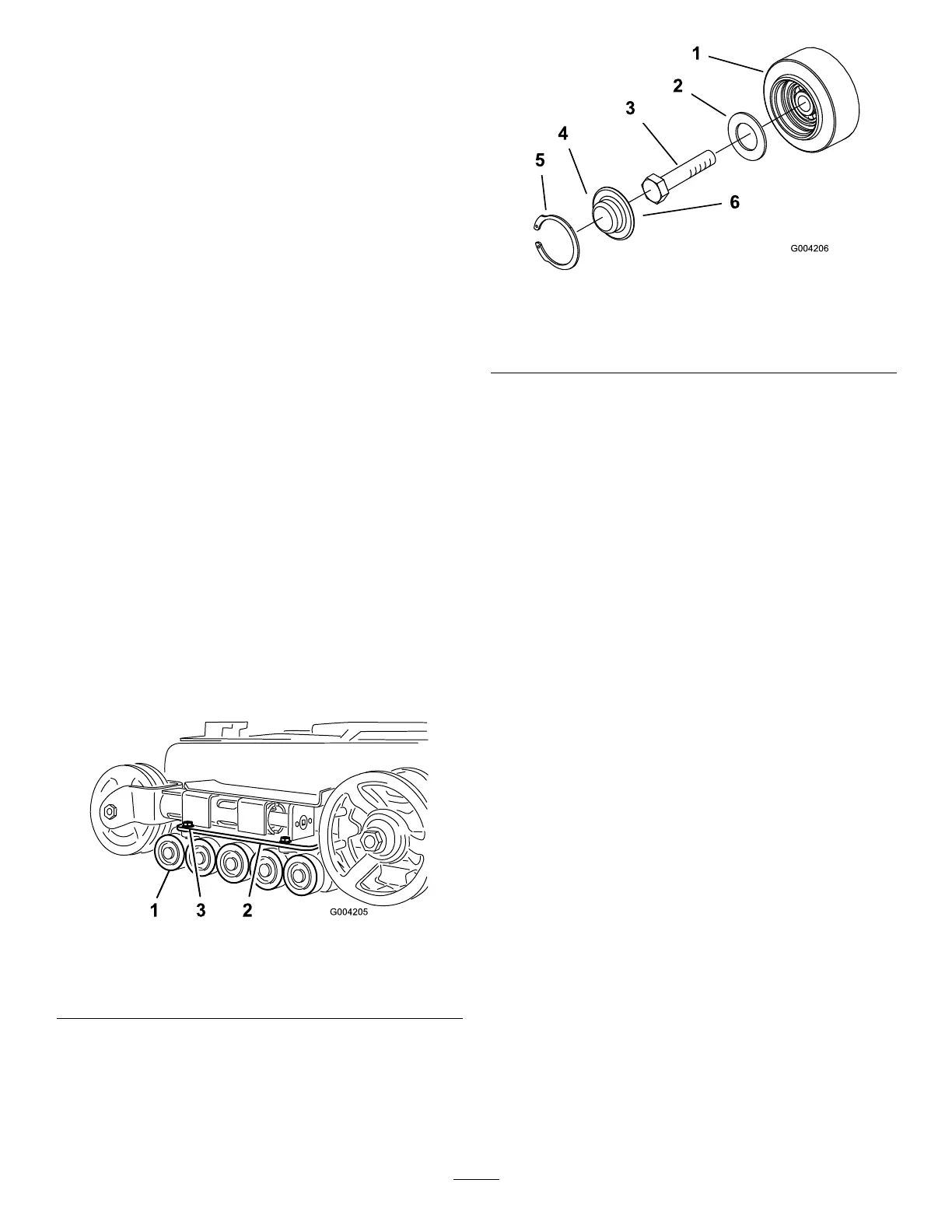

3.Removethesnapringandcapfromaroadwheel

(Figure45).

Figure45

1.Roadwheel4.Roadwheelcap

2.Gasket5.Snapring

3.Bolt6.Addgreaseunderthecap

4.Checkthegreaseunderthecapandaroundthe

gasket(Figure45).Ifitisdirty,gritty,ordepleted,

cleanoutallofthegrease,replacethegasket,and

addnewgrease.

5.Ensurethattheroadwheelturnssmoothlyonthe

bearing.Ifitisfrozen,replacetheroadwheelas

describedintheRoadWheelKitInstallationInstructions

orcontactyourAuthorizedServiceDealerforrepair.

6.Placethegreasedroadwheelcapoverthebolthead

(Figure45).

7.Securetheroadwheelcapwiththesnapring

(Figure45).

8.Repeatsteps3through7fortheotherroadwheels.

9.Installeachtrackguidetothetractionunitframe

usingthefastenersyouremovedpreviously.Torque

theboltsto67to83ft-lb(91to112N-m).

10.Installthetracks;refertoReplacingtheTracks.

34

Loading...

Loading...