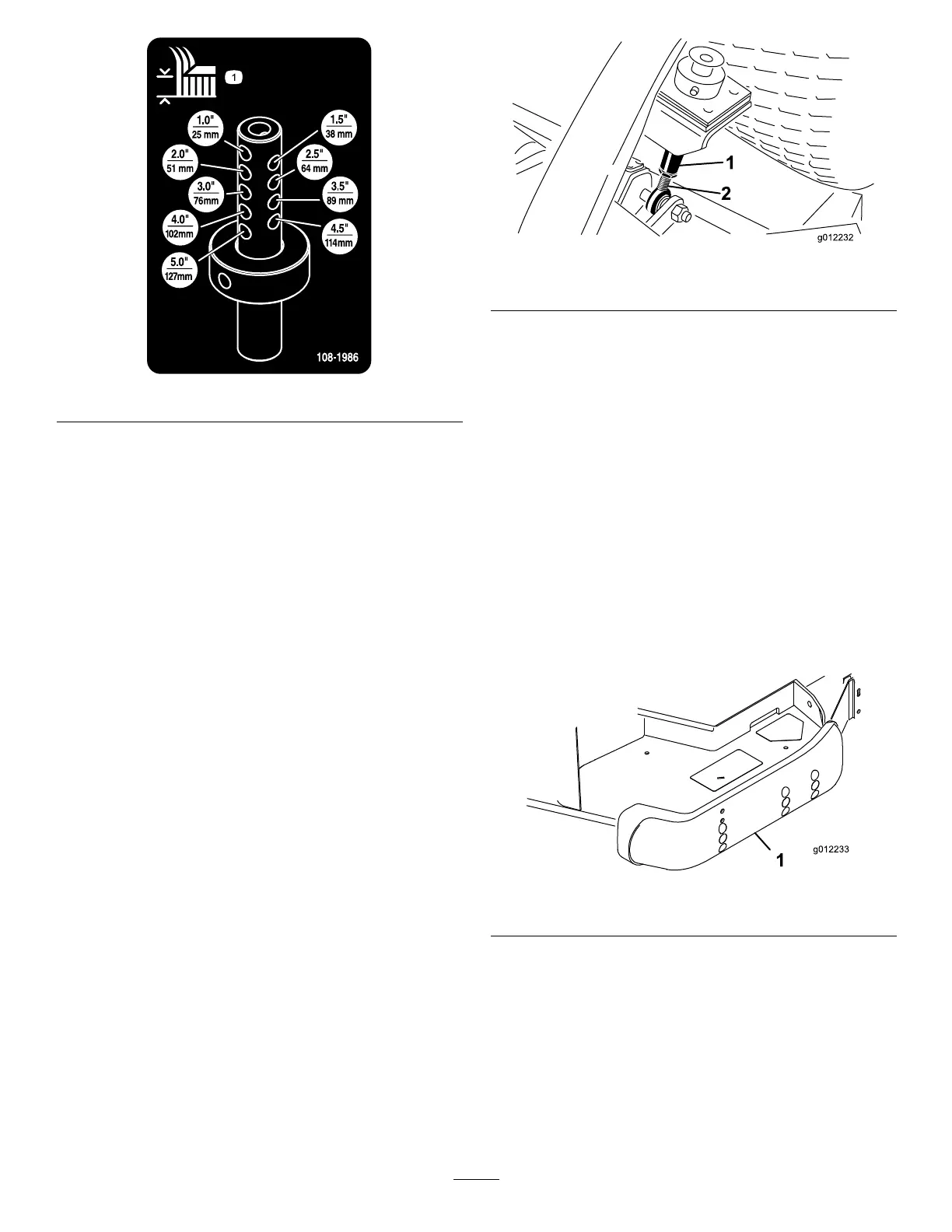

Figure10

7.Securetheadjustmentwiththeclevispinandhair

pin.

Note:Positiontheheadoftheclevispintoward

thefrontofthedeck,ifpossible.

Note:Whenusing1inch(25mm),1-1/2inch(38

mm),oroccasionally2inch(51mm)height–of–cut,

movetheskidsandrollertothehighestholes.

AdjustingtheCuttingUnit

Pitch

Cuttingunitpitchisthedifferenceinheight-of-cut

fromthefrontofthebladeplanetothebackofthe

bladeplane.Tororecommendsabladepitchof1/4

inch(6mm).Thatisthebackofthebladeplaneis1/4

inch(6mm)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut.

3.Rotate1bladesothatitpointsstraightforward.

4.Usingashortruler,measurefromtheoortothe

fronttipoftheblade.Rotatethebladetiptotherear

andmeasurefromtheoortothetipoftheblade.

5.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

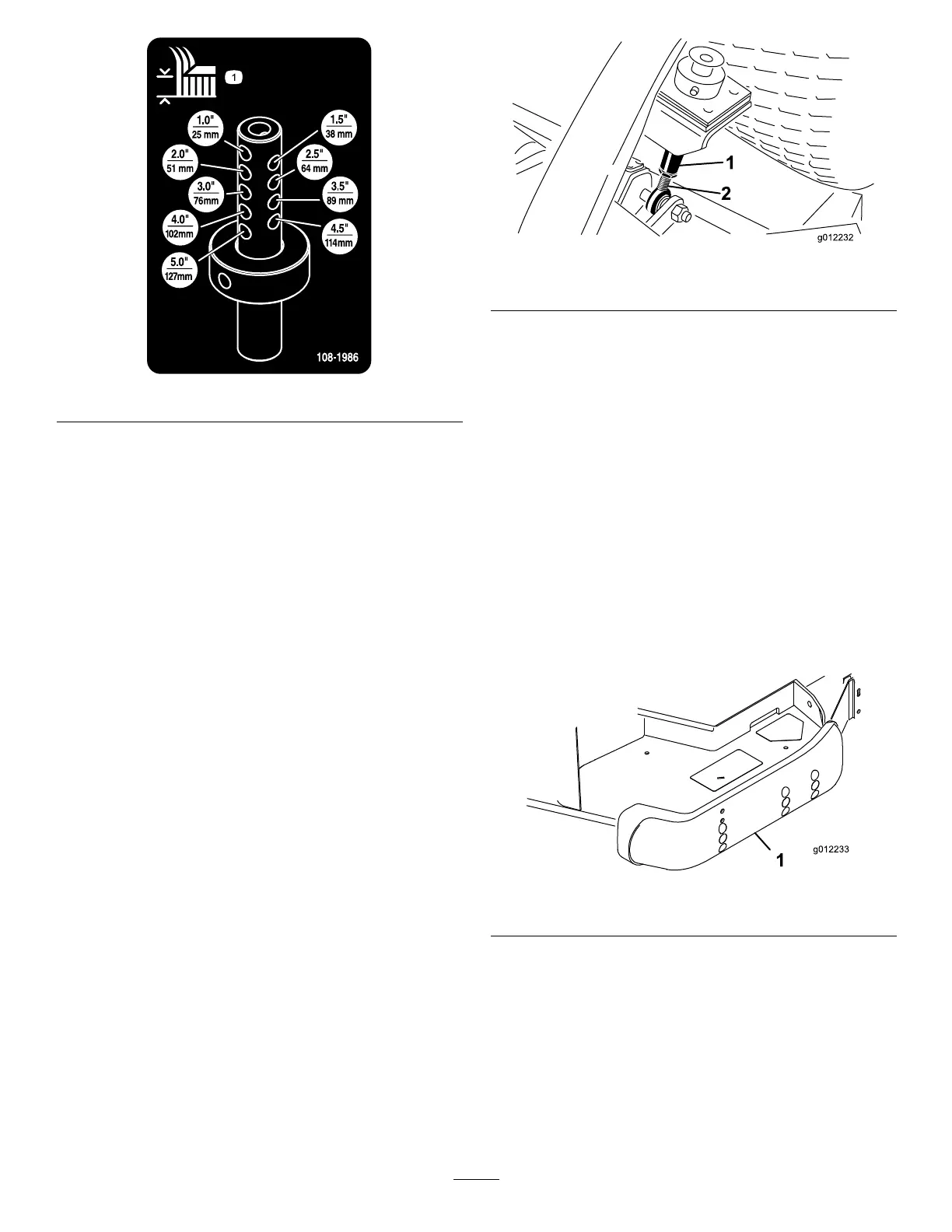

6.Loosenthejamnutsonthebottomofthe

height-of-cutrods(

Figure11).

Figure11

1.Height-of-cut

2.Jamnut

7.Rotatetheheight-of-cutrodstoraiseorlowerthe

rearofthecuttingunitandattainthecorrectcutting

unitpitch.

8.Tightenthejamnuts.

AdjustingtheSkids

Theskidsshouldbemountedinthelowerposition

whenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(

Figure12).

Figure12

1.Skid

AdjustingtheRollers

Note:Ifthecuttingunitistobeusedinthe1or1-1/2

inch(25or38mm)height-of-cutsetting,thecutting

unitrollersmustberepositionedinthetopbracket

holes.

1.Removethescrewandnutsecuringtherollershaft

tothedeckbracket(Figure13).

14

Loading...

Loading...