Figure26

3.Rotatetheoppositeendofthebladeforward.

Measurebetweenthecuttingunitandcuttingedge

ofthebladeatthesamepositionasinstep2The

differencebetweenthedimensionsobtainedinsteps

2and3mustnotexceed1/8inch(3mm).Ifthe

dimensionexceeds1/8inch(3mm),replacethe

bladebecauseitisbent;refertoRemovingthe

CuttingBlade.

RemovingandInstallingthe

Blade(s)

Theblademustbereplacedifasolidobjectishit,the

bladeisout-of-balance,worn,orbent.Alwaysuse

genuineTororeplacementbladestoensuresafetyand

optimumperformance.Neverusebladesmadebyother

manufacturersbecausetheycouldbedangerous.

1.Raisethecuttingunittothehighestposition,engage

theparkingbrake,stoptheengine,andremovethe

ignitionkey.Blockthecuttingunittopreventitfrom

accidentallyfalling.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(

Figure27).

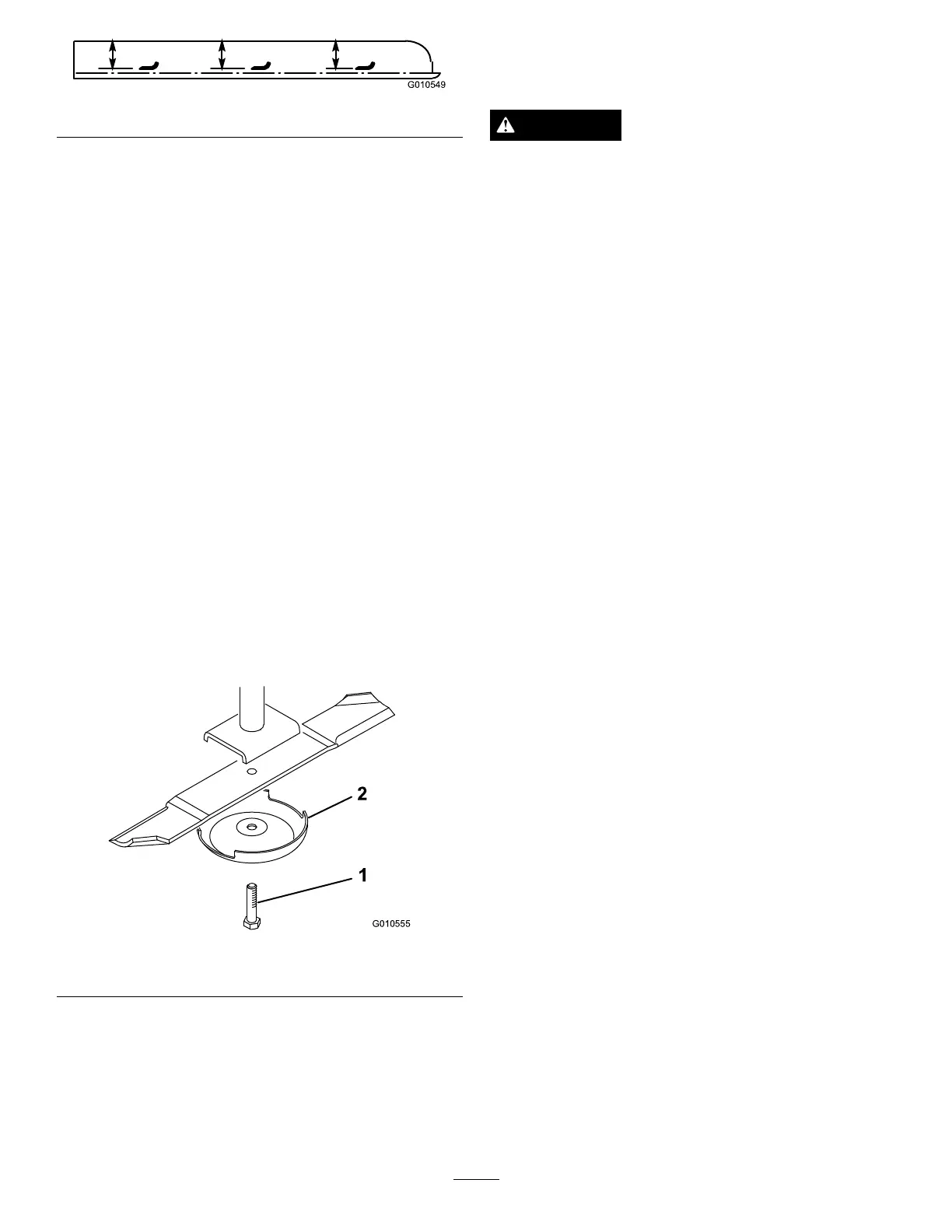

Figure27

1.Bladebolt2.Anti-scalpcup

3.Installtheblade-sailfacingtowardthecutting

unit-withtheanti-scalpcupandbladebolt.Tighten

thebladeboltto85-110ft-lb(115-149N-m).

Important:Thecurvedpartoftheblademust

bepointingtowardtheinsideofthecuttingunit

toensurepropercutting.

InspectingandSharpeningthe

Blade(s)

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

•Neverweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

Twoareasmustbeconsideredwhencheckingand

servicingthecuttingblade:thesailandthecuttingedge.

Bothcuttingedgesandthesail,whichistheturnedup

portionoppositethecuttingedge,contributetoagood

quality-of-cut.Thesailisimportantbecauseitpullsgrass

upstraight,therebyproducinganevencut.However,

thesailwillgraduallyweardownduringoperation,and

thisconditionisnormal.Asthesailwearsdown,the

quality-of-cutwilldegradesomewhat,althoughthe

cuttingedgesaresharp.Thecuttingedgeoftheblade

mustbesharpsothatthegrassiscutratherthantorn.

Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedges

tocorrectthiscondition.

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthePTOleverin

theOffposition,stoptheengine,andremovethe

ignitionkey.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsofthe

blademeet(

Figure28).Sincesandandabrasive

materialcanwearawaythemetalthatconnects

theatandcurvedpartsoftheblade,checkthe

bladebeforeusingthemachine.Ifwearisnoticed

(

Figure28),replacetheblade;refertoRemovingthe

CuttingBlade.

21

Loading...

Loading...