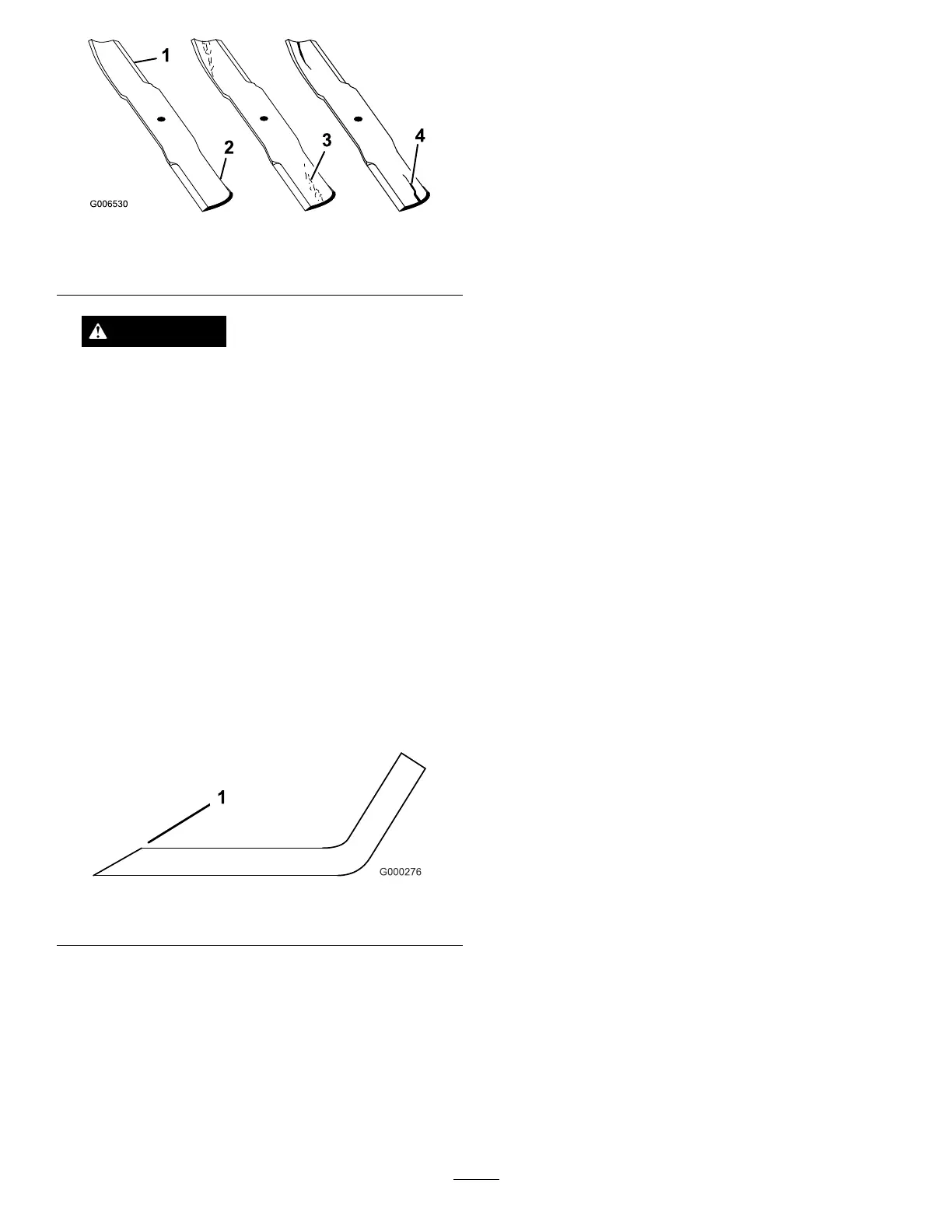

Figure28

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

WARNING

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

(Figure28).Eventually,apieceoftheblademay

breakoffandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyourself

orbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

3.Examinethecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopsideofthecuttingedgeandmaintainthe

originalcuttingangletoensuresharpness(Figure29).

Thebladewillremainbalancedifthesameamount

ofmetalisremovedfrombothcuttingedges.

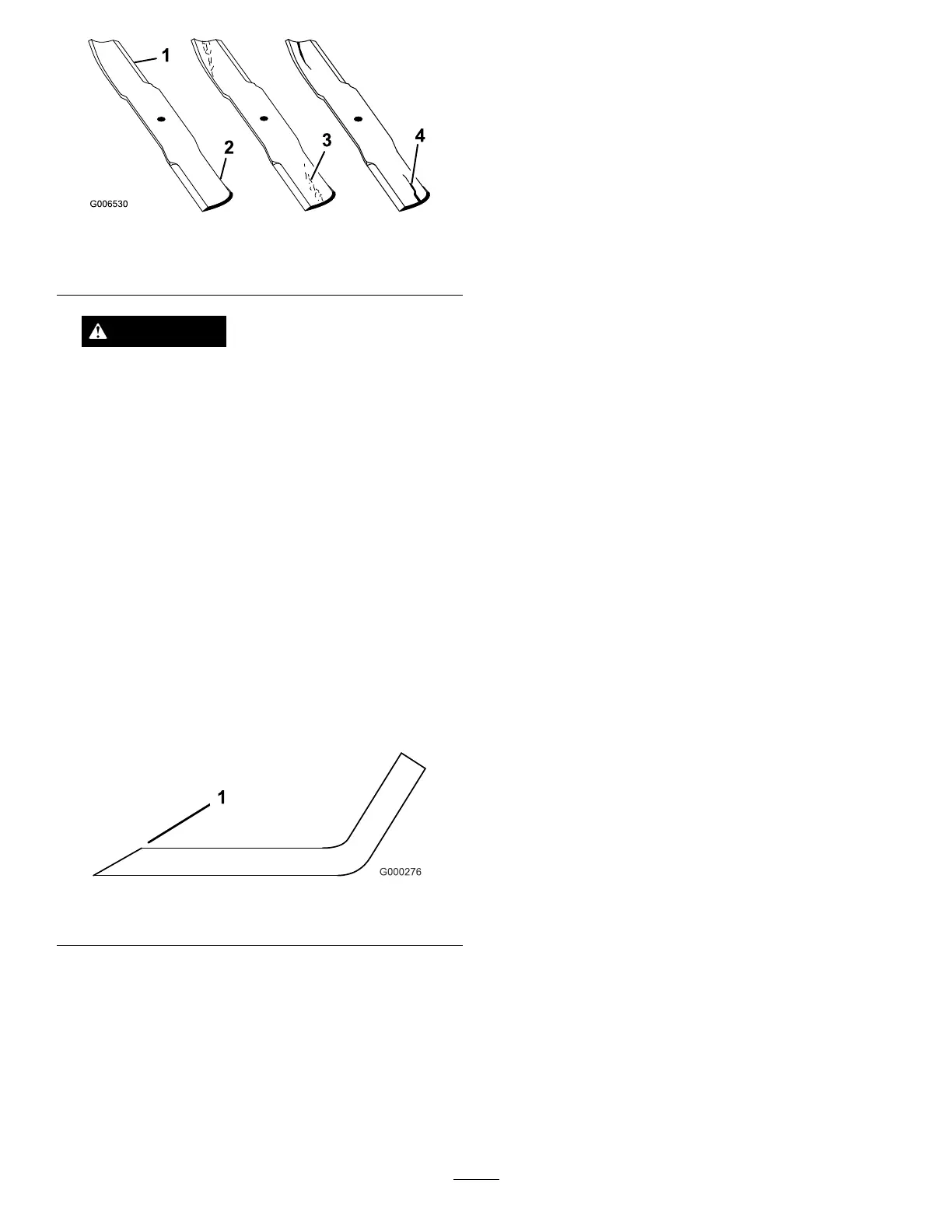

Figure29

1.Sharpenatoriginalangle

Note:Removethebladesandsharpenthemona

grinder;refertoRemovingtheCuttingBlades.After

sharpeningthecuttingedges,installthebladewith

theanti-scalpcupandbladebolt.Thebladesails

mustbeontopoftheblade.Tightenthebladebolt

to85-110ft-lb(115-149N-m).

CheckingandCorrecting

MismatchofBlades

Ifthereismismatchbetweentheblades,thegrasswill

appearstreakedwhenitiscut.Thisproblemcanbe

correctedbymakingsurethatthebladesarestraightand

allofthebladesarecuttingonthesameplane.

1.Usinga3foot(1meter)longcarpenterslevel,nd

alevelsurfaceontheshopoor.

2.Raisetheheight-of-cuttothehighestposition;refer

toAdjustingtheHeight-of-Cut.

3.Lowerthecuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunit.

4.Rotatethebladesuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipof

thecuttingedge.Rememberthisdimension.Then

rotatethesamebladesothattheoppositeendis

forward,andmeasureagain.Thedifferencebetween

thedimensionsmustnotexceed1/8inch(3mm).

Ifthedimensionexceeds1/8inch(3mm),replace

thebladebecauseitisbent.Makesuretomeasure

alloftheblades.

5.Comparethemeasurementsoftheouterbladeswith

thecenterblade.Thecenterblademustnotbemore

than3/8inch(10mm)lowerthantheouterblades.

Ifthecenterbladeismorethan3/8inch(10mm)

lowerthantheouterblades,proceedtostep

6and

addshimsbetweenthespindlehousingandthe

bottomofthecuttingunit.

6.Removethebolts,atwashers,lockwashers,and

nutsfromtheouterspindleintheareawhere

theshimsmustbeadded.Toraiseorlowerthe

blade,addashim,PartNo.3256-24,betweenthe

spindlehousingandthebottomofthecuttingunit.

Continuetocheckthealignmentofthebladesand

addshimsuntilthetipsofthebladesarewithinthe

requireddimension.

Important:Donotusemorethanthreeshimsat

anyoneholelocation.Usedecreasingnumbers

ofshimsinadjacentholesifmorethanoneshim

isaddedtoanyoneholelocation.

7.Installthebeltcovers.

ReplacingtheDriveBelt

Thebladedrivebelt,tensionedbythespringloaded

idlerpulley,isverydurable.However,aftermanyhours

ofuse,thebeltwillshowsignsofwear.Signsofaworn

beltare:squealingwhenbeltisrotating,bladesslipping

whencuttinggrass,frayededges,burnmarksandcracks.

Replacethebeltifanyoftheseconditionsareevident.

22

Loading...

Loading...