pincotters(Figure23).Headofclevispintobe

positionedtowardthefrontofthedeck.

10.Installa1/2x3/4inchboltandawashertotopof

eachheightofcutrod(

Figure23).

ServicingtheBushingsinthe

CastorArms

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,

thebushingswillwear.Tocheckthebushings,movethe

castorforkbackandforthandfromsidetoside.Ifthe

castorspindleislooseinsidethebushings,thebushings

arewornandmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(

Figure24).Alsodrivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

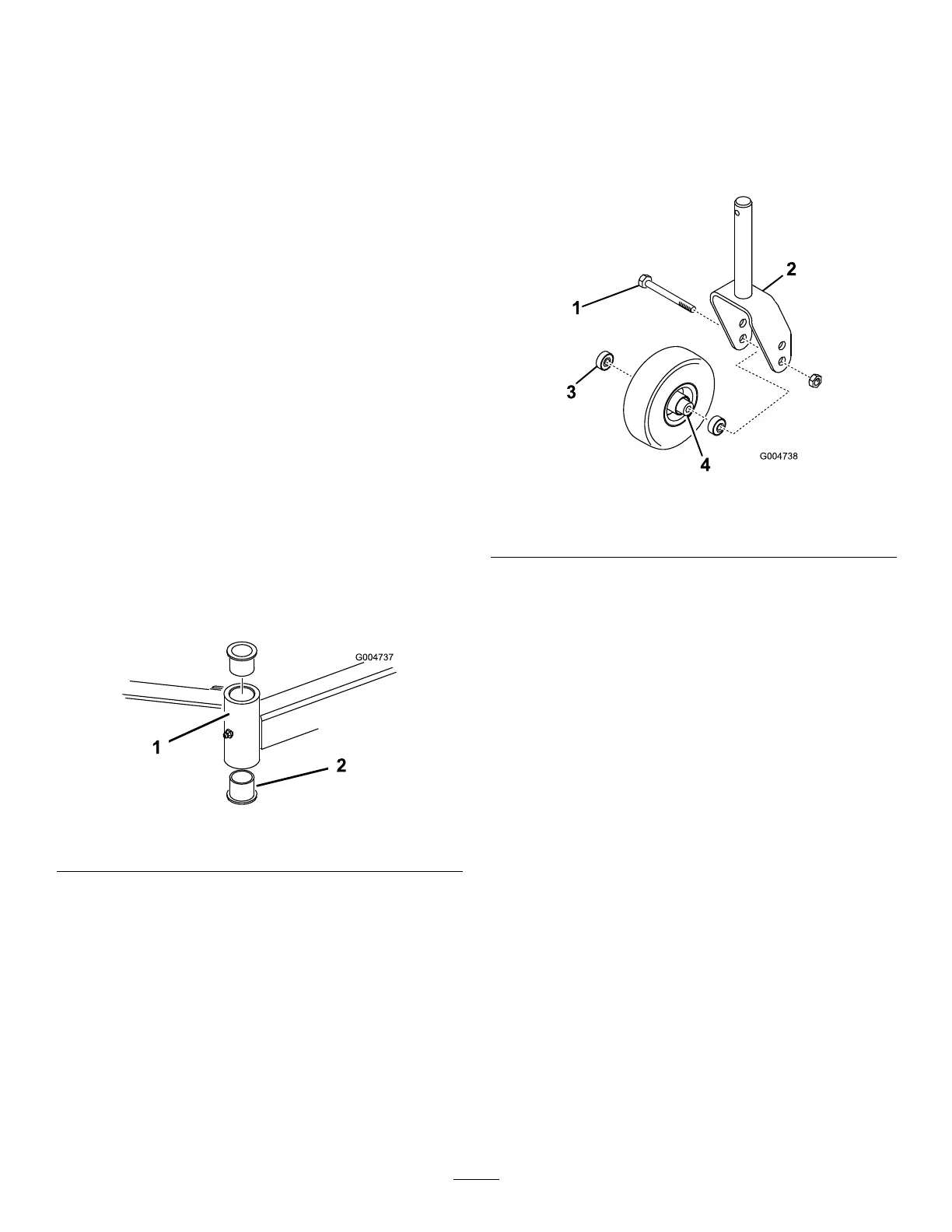

Figure24

1.Castorarmtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitif

damaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

ServicingtheCastorWheels

andBearings

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure25).

Graspthecastorwheelandslidetheboltoutofthe

forkorpivotarm.

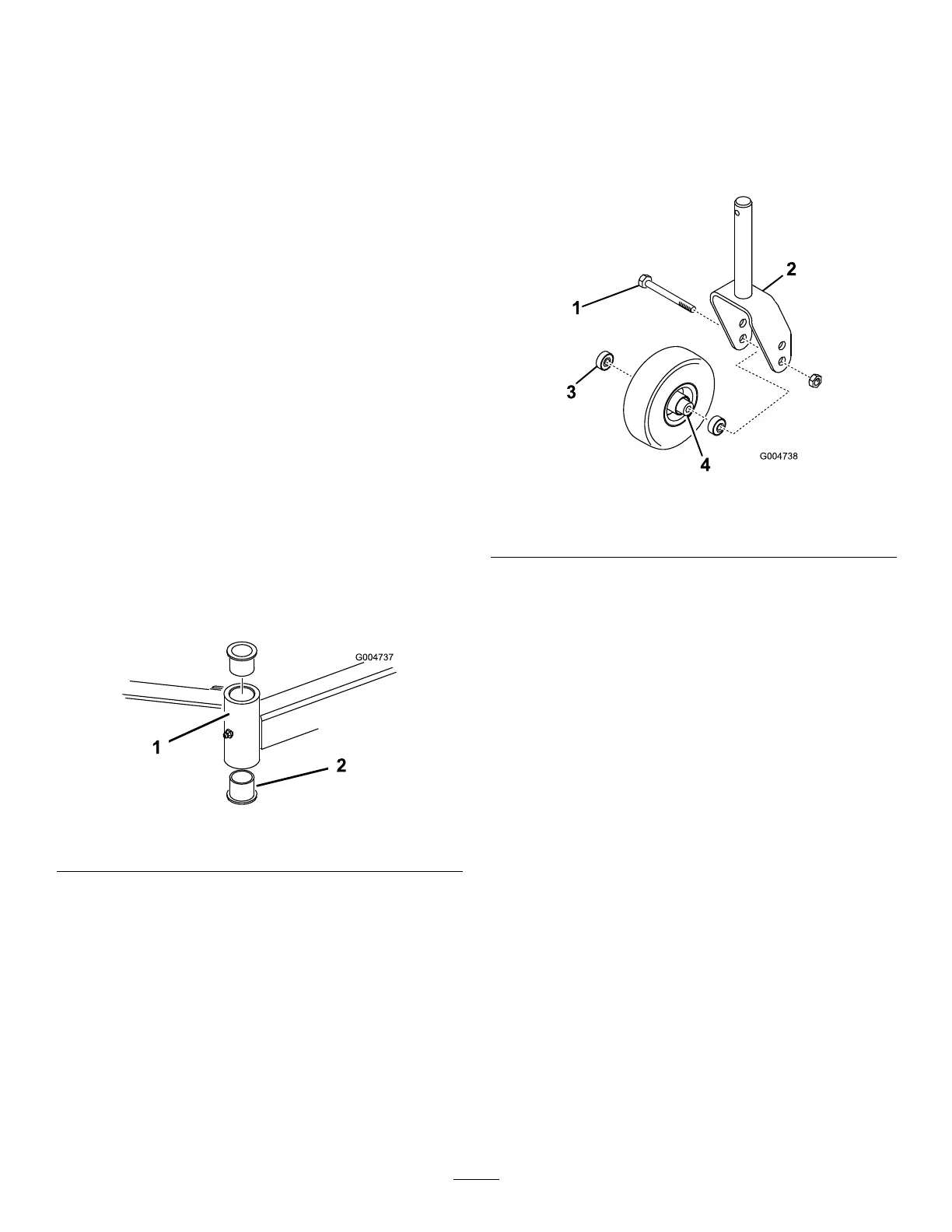

Figure25

1.Castorwheel3.Bearing(2)

2.Castorfork

4.Bearingspacer

2.Removethebearingfromthewheelhubandallow

thebearingspacertofallout(Figure25).Remove

thebearingfromtheoppositesideofthewheelhub.

3.Checkthebearings,spacer,andinsideofthewheel

hubforwear.Replaceanydamagedparts.

4.Toassemblethecastorwheel,pushthebearinginto

thewheelhub.Wheninstallingthebearings,press

ontheouterraceofthebearing.

5.Slidethebearingspacerintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

6.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthePTOleverin

theOffposition,stoptheengine,andremovethe

ignitionkey.Blockthecuttingunittopreventitfrom

accidentallyfalling.

2.Rotatethebladeuntiltheendsfaceforwardand

backward.Measurefromtheinsideofthecutting

unittothecuttingedgeatthefrontoftheblade

(Figure26),andrememberthisdimension.

20

Loading...

Loading...