•Model30303,72inchRearDischarge

•Model30304,72inchGuardian

2

InstallingtheCastorWheel

Assemblies

Partsneededforthisprocedure:

2

Castorwheelassembly

Procedure

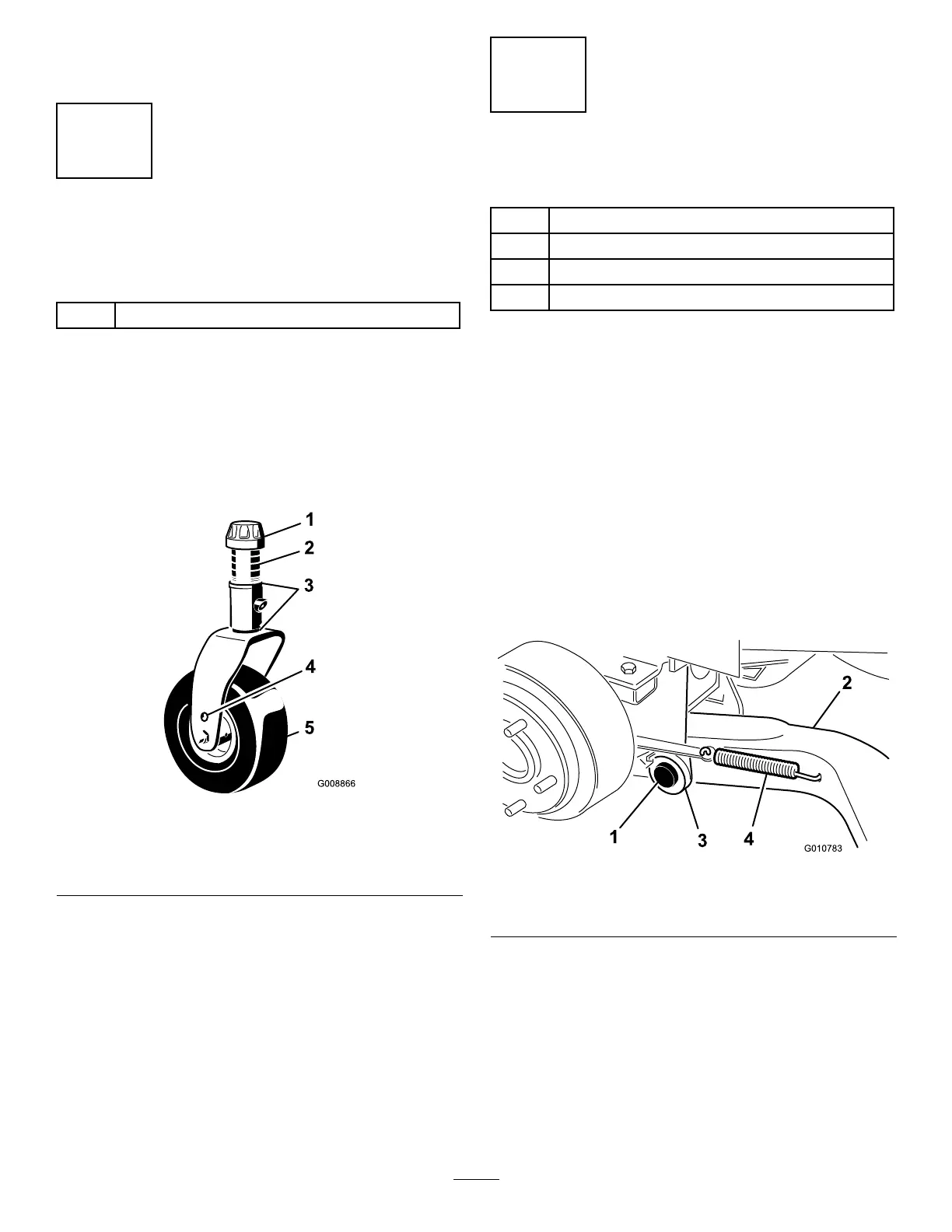

Thethrustwashers,spacers,andtensioningcapshave

beeninstalledonthecastorwheelspindlesforshipping.

1.Removethetensioningcapsfromthespindle

shaftsandslideoffthespacersandthrustwashers

(

Figure2).

Figure2

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Thrustwashers

2.Slidethespacersontothecastorspindletogetthe

desiredheight-of-cut;referto

Figure7&Figure8

todeterminethecombinationsofspacersforthe

setting.Slideathrustwasherontothespindle,push

thecastorthroughthecastorarm.Installanother

thrustwasherandtheremainingspacersontothe

spindleandinstallthetensioningcaptosecurethe

assembly(Figure2).

Important:Thethrustwashers,notthespacers,

mustcontactthetopandbottomofthecastor

arm.

3

InstallingtheLiftArms

Partsneededforthisprocedure:

1

Liftarm,right

1

Liftarm,left

2Pivotpinassembly

2

Cotterpin

Procedure

1.Ononesideofthetractionunit,loosen(donot

remove)thewheelnutssecuringthewheelandtire

assemblytothefrontwheelstuds.

2.Jackupthemachineuntilthefrontwheelisoffof

theoor.Usejackstandsorblockthemachineto

preventitfromaccidentallyfalling.

3.Removethewheelnutsandslidethewheelandtire

assemblyoffofthestuds.

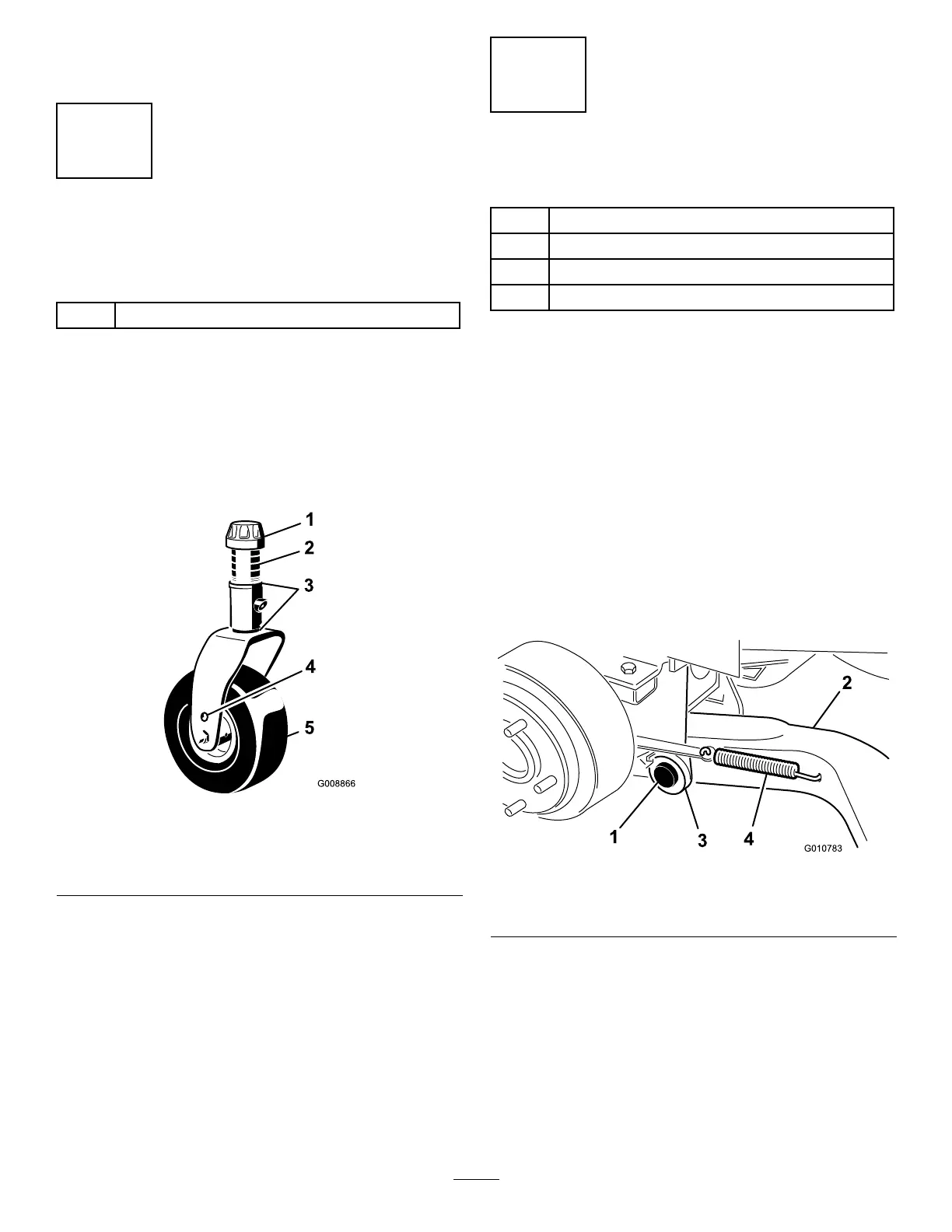

4.Mountaliftarmtothepivotbracketwithapivotpin

andacotterpin(

Figure3).Mounttheliftarmwith

thebendpositionedoutward.

Figure3

1.Pivotpin3.Pivotbracket

2.Liftarm

4.Brakereturnspring

5.Hookthebrakereturnspringintotheholeinthe

liftarm(Figure3).

6.Installthewheelandtireassembly.Torquethewheel

nutsto75–80ft-lb(102–108N-m).

7.Repeattheprocedureontheoppositesideofthe

machine.

9

Loading...

Loading...