installed)andtheremainingspacersontothe

spindleshaft.Installthetensioningcapto

securetheassembly.

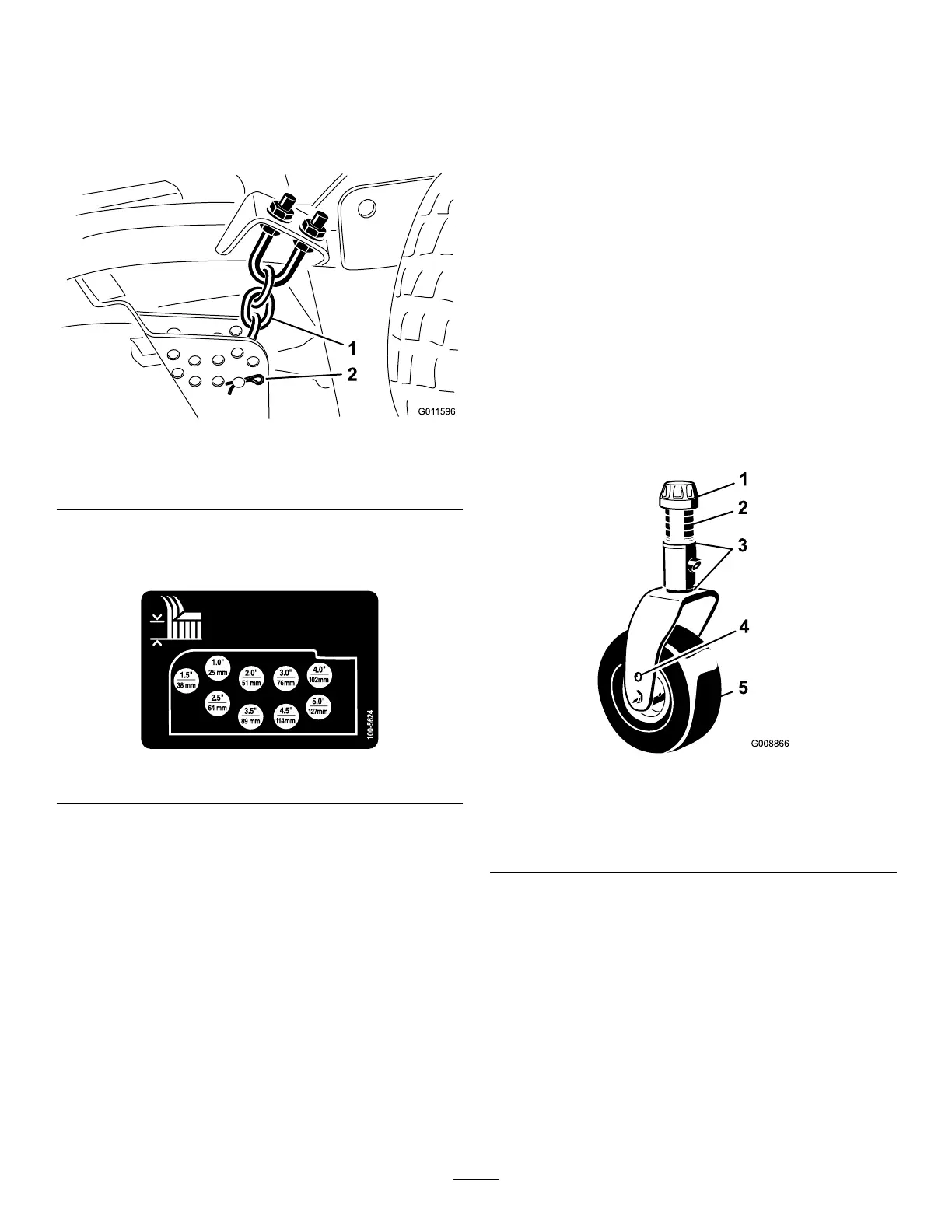

5.Removethehairpincotterandclevispin

securingtheheight-of-cutchainstotherearof

thecuttingunit(Figure20).

g011596

Figure20

1.Height-of-cutchain2.Clevispinandhairpin

cotter

6.Mounttheheight-of-cutchainstothedesired

height-of-cuthole(Figure21)withtheclevispin

andhairpincotter.

decal100-5624nc

Figure21

Note:Whenusing25mm(1inch),38mm

(1-1/2inch),oroccasionally51mm(2inch)

height-of-cut,movetheskidsandgagewheels

tothehighestposition.

SideCuttingUnits

Toadjusttheheight-of-cutonthesidecuttingunits,

addorremoveanequalnumberofspacersfromthe

castorforks,positionthecastorwheelaxlesinthe

highorlowheight-of-cutholesinthecastorforks,and

securethepivotarmstotheselectedheight-of-cut

bracketholes.

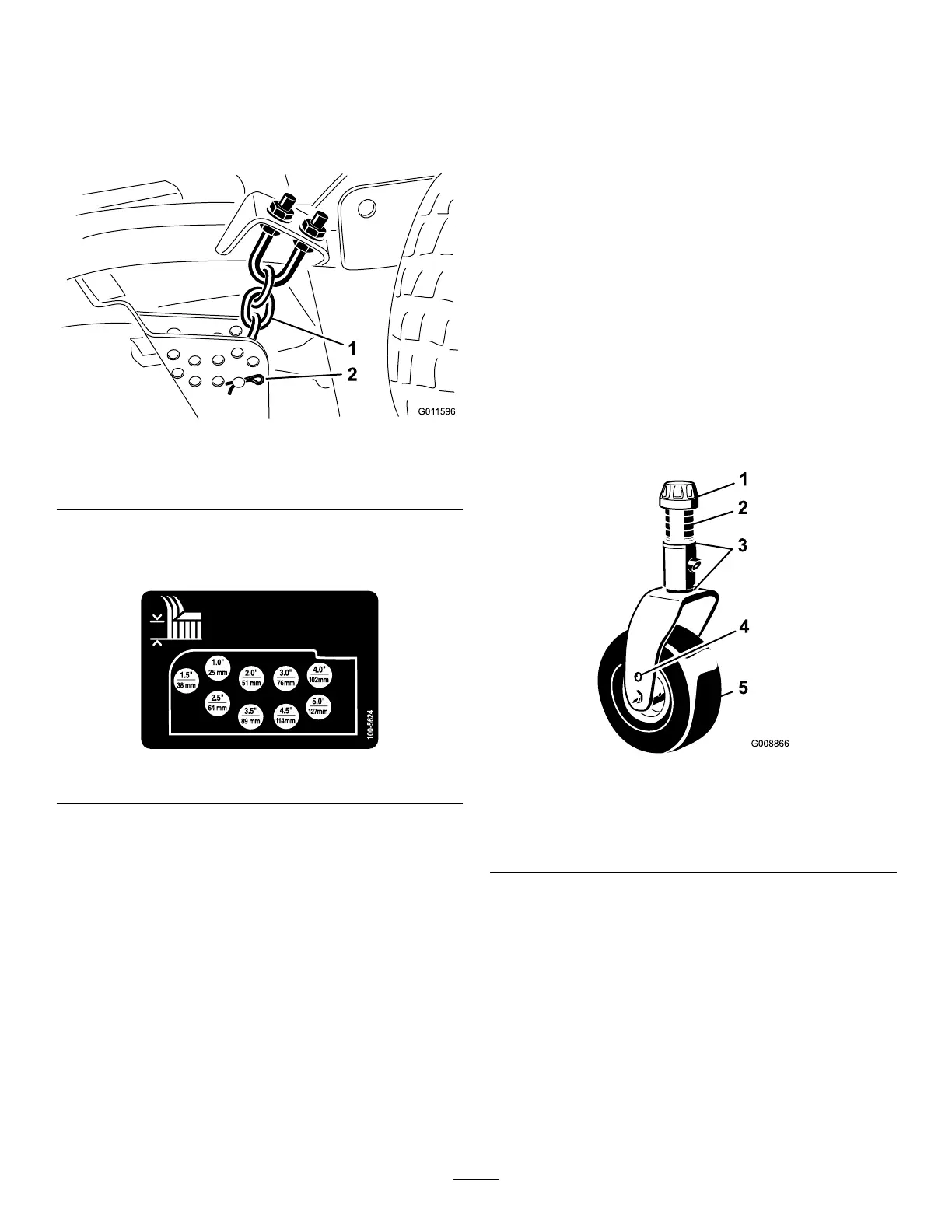

1.Positionthecastorwheelaxlesinthesame

holesinallofthecastorforks(Figure22and

Figure24).Refertothefollowingchartto

determinethecorrectholeforthesetting.

2.Removethetensioningcapfromthespindle

shaft(Figure22)andslidethespindleoutof

castorarm.Putthetwoshims(3mm[1/8

inch])ontospindleshaftastheywereoriginally

installed.Theseshimsarerequiredtoachieve

alevelacrosstheentirewidthofthecutting

units.Slidetheappropriatenumberof13mm

(1/2inch)spacersontothespindleshafttoget

thedesiredheight-of-cut;thenslidethewasher

ontotheshaft.

g008866

Figure22

1.Tensioningcap4.Toaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting.

30

Loading...

Loading...