decal100-5622nc

Figure23

3.Pushthecastorspindlethroughthecastorarm.

Installtheshims(asoriginallyinstalled)andthe

remainingspacersontothespindleshaft.Install

thetensioningcaptosecuretheassembly.

4.Removethehairpincotterandclevispinsfrom

thecastorpivotarms(Figure24).

5.Rotatetensionrodtoraiseorlowerpivotarm

untilholesarealignedwithselectedheight-of-cut

bracketholesinthecuttingunitframe(Figure

24andFigure25).

6.Inserttheclevispinsandinstallthehairpin

cotters.

7.Rotatetensionrodcounterclockwise(nger

tight)toputtensiononadjustment.

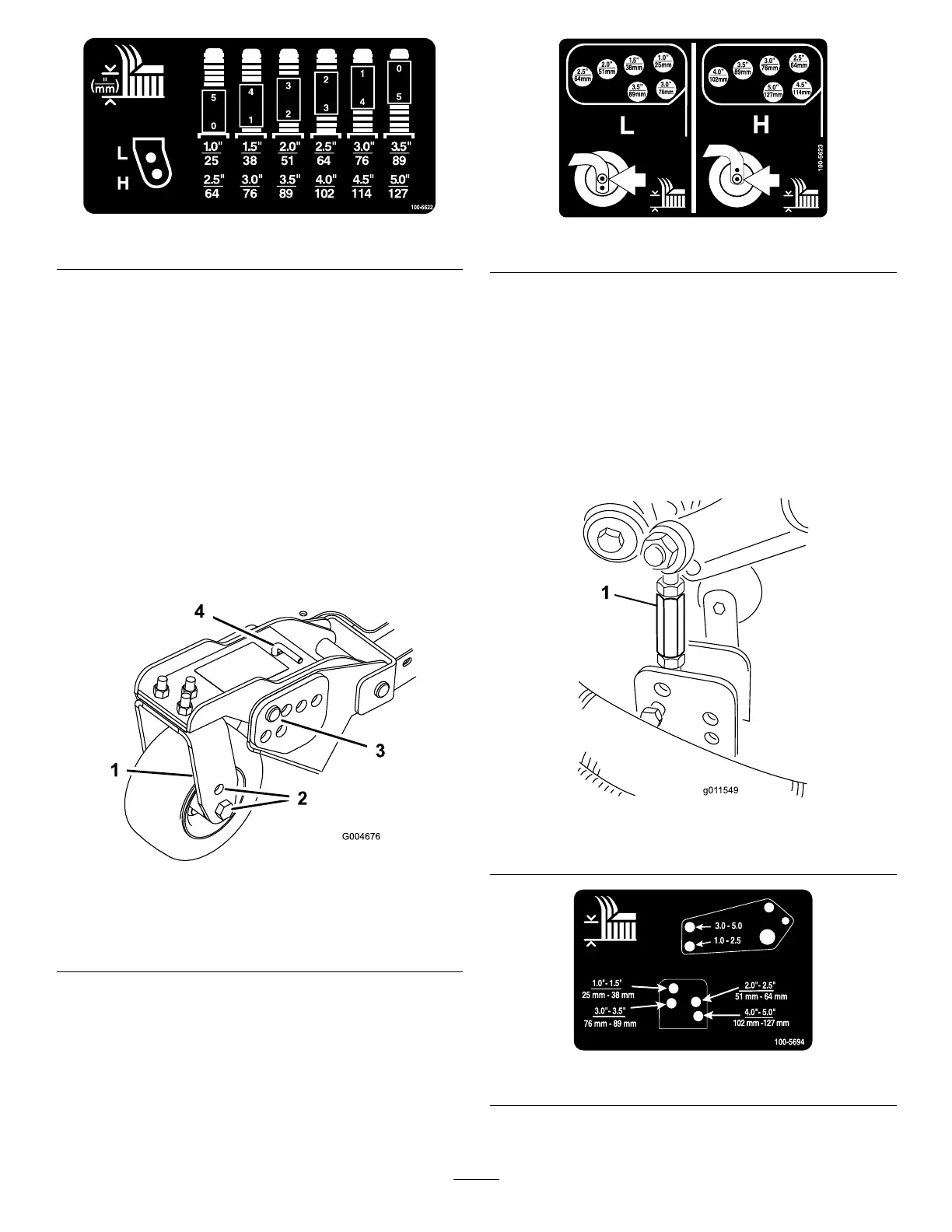

g004676

Figure24

1.Castorpivotarm3.Clevispinandhairpin

cotter

2.Axlemountingholes4.Tensionrod

decal100-5623nc

Figure25

8.Removethehairpincottersandclevispins

securingthedamperlinkstothecuttingunit

brackets(Figure26).Alignthedamperlink

holeswiththeselectedheight-of-cutbracket

holesinthecuttingunitframe(Figure27),insert

theclevispins,andinstallthehairpincotters.

Important:Thedamperlinklengthshould

neverbeadjusted.Thelengthbetween

theholecentersshouldbe13.7cm(5-3/8

inches).

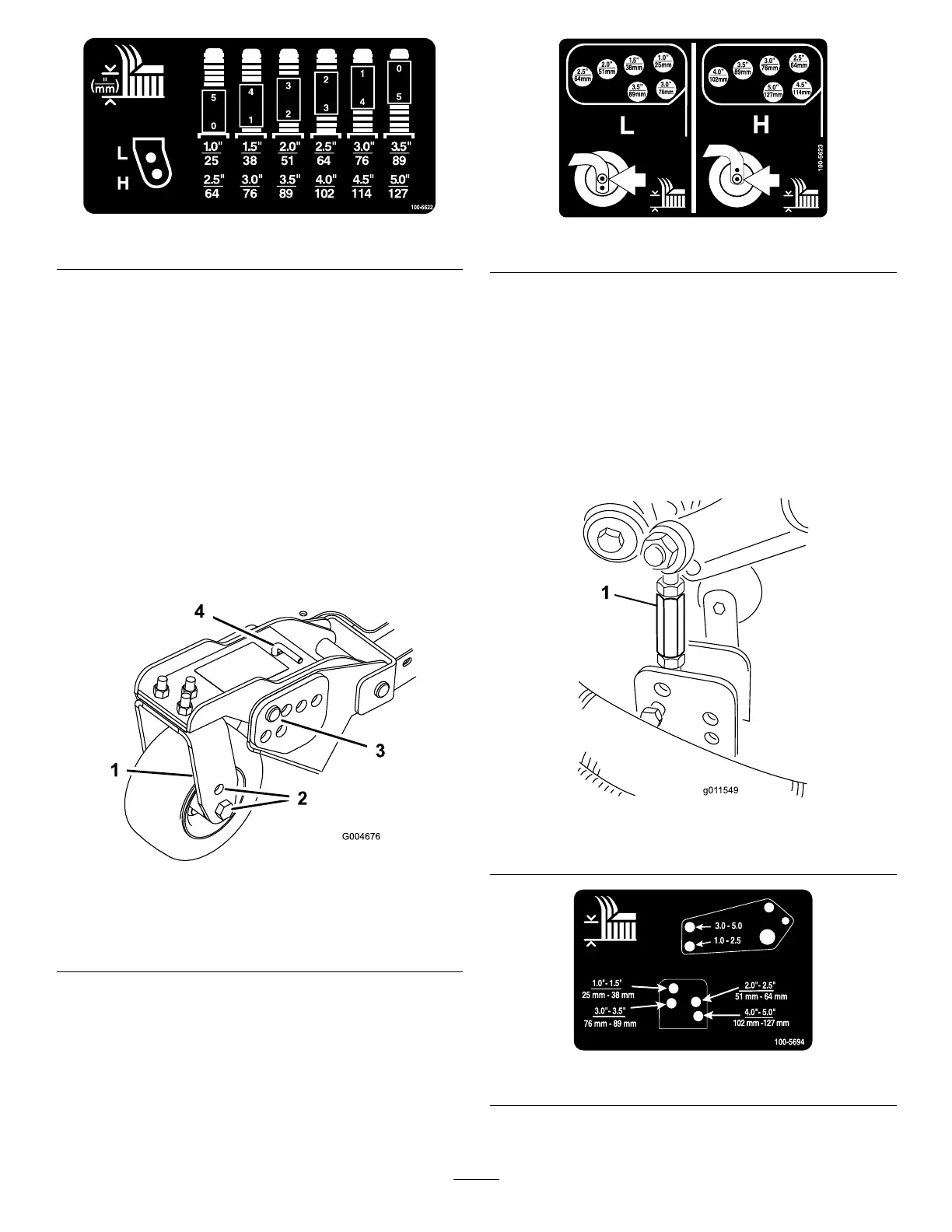

g011549

Figure26

1.Damperlink

decal100-5694nc

Figure27

31

Loading...

Loading...