Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst2hours

•Tightenthecastorwheelnuts

Aftertherst10hours

•Tightenthecastorwheelnuts

•T orquethebladebolts

Beforeeachuseordaily

•Lubricatethegreasettings

•Checktheblades

Every50hours

•Checkthegearboxlubricant

•Checkthebladedrivebeltadjustment

•Cleanunderthecuttingunitbeltcovers

•Tightenthecastorwheelnuts

•T orquethebladebolts

Every400hours

•Changethegearboxlubricant

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

PreMaintenance

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

Lubrication

ServiceInterval:Beforeeachuseordaily

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsdailyorimmediatelyafterevery

washing.

Lubricatethefollowingareas:

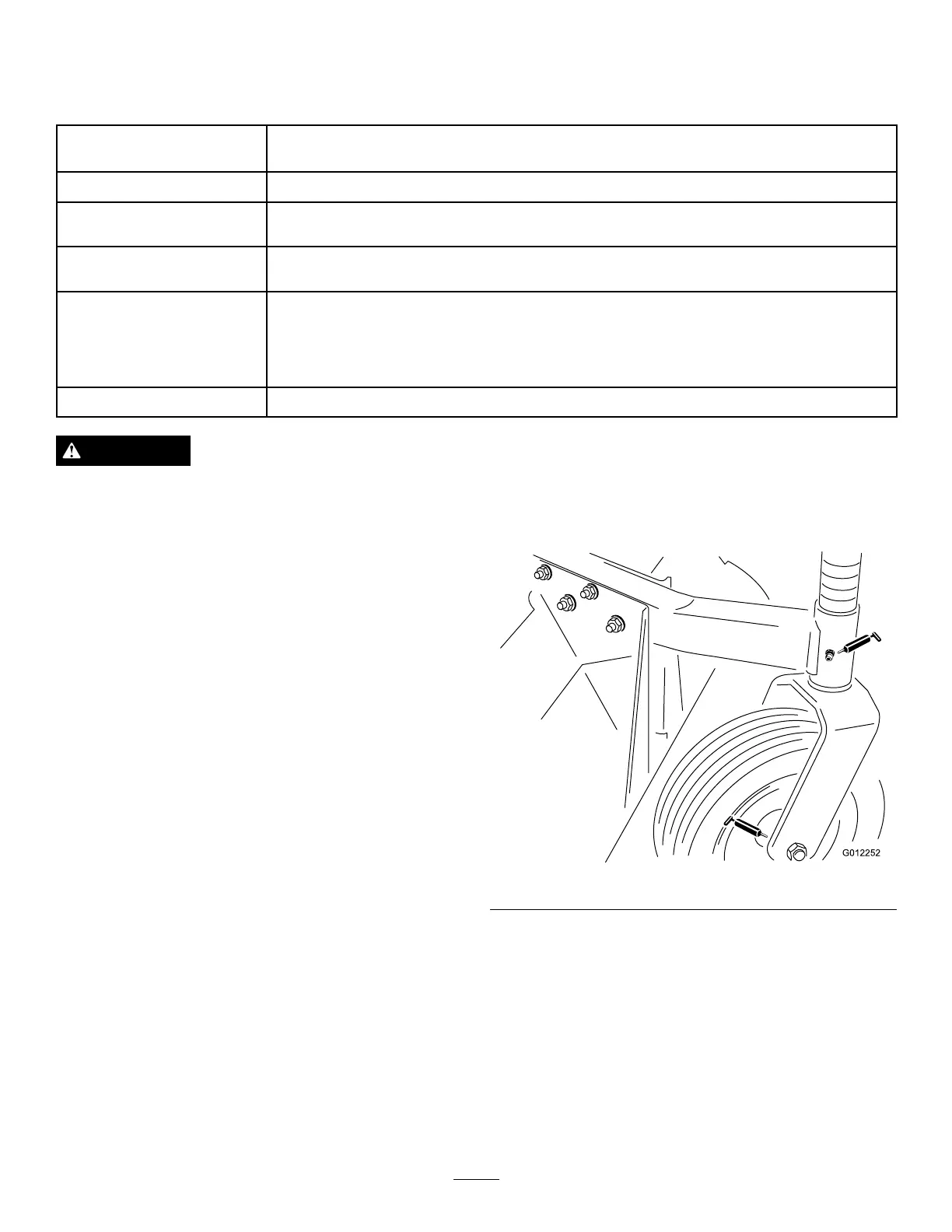

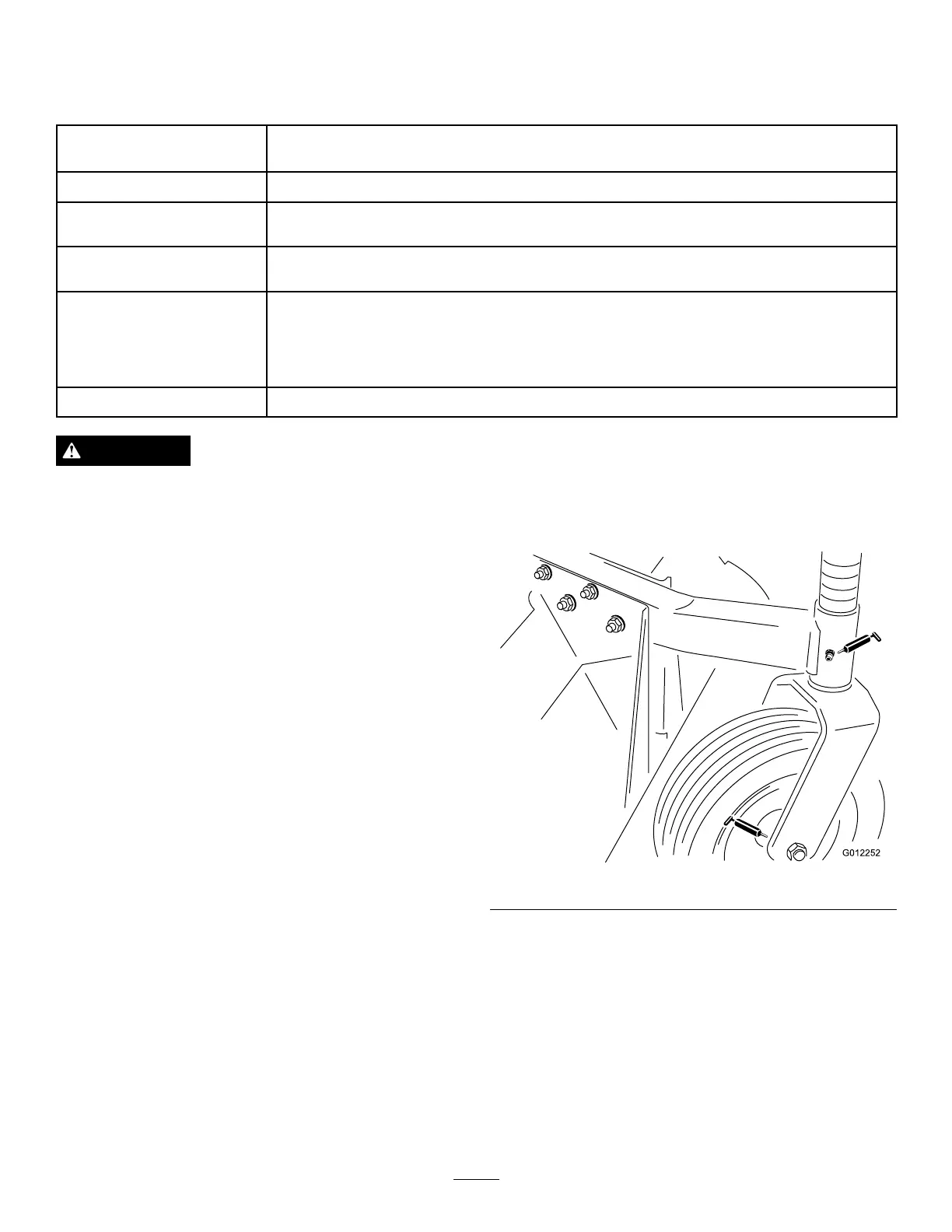

•Frontcastorspindlebushings(

Figure15)

•Castorwheelbearings(Figure15)&Figure16)

•Bladespindlebearings(Figure17)

•Idlerarmpivot(Figure17)

•Rightandleftpusharmballjoints(

Figure17)

Alsoremovetherearcastorspindleshaftfromthecastor

armandcoatthehexshaftwithNo.2generalpurpose

lithiumbasegreaseormolybdenumbasegreaseevery

50hours(

Figure16).

Figure15

16

Loading...

Loading...