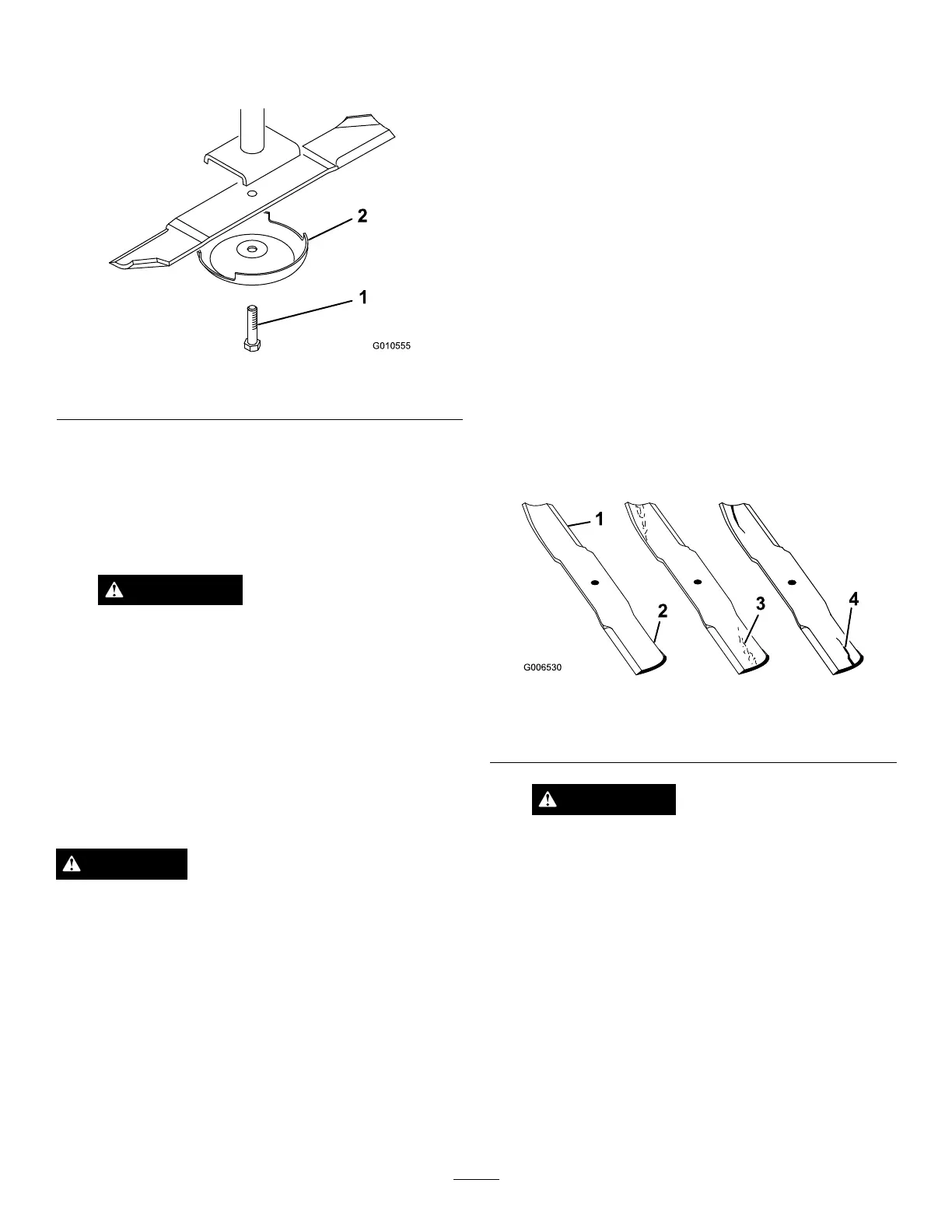

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(Figure27).

Figure27

1.Bladebolt2.Anti-scalpcup

3.Installtheblade-sailfacingtowardthecuttingunit-with

theanti-scalpcupandbladebolt.Tightentheblade

boltto85-110ft-lb(115-149N-m).

Important:Thecurvedpartoftheblademustbe

pointingtowardtheinsideofthecuttingunitto

ensurepropercutting.

WARNING

Donottrytostraightenabladethatisbent,

andneverweldabrokenorcrackedblade.

Alwaysuseanewbladetoensurecontinued

safetycerticationoftheproduct.

InspectingandSharpeningthe

Blade(s)

ServiceInterval:Beforeeachuseordaily

Every50hours

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

•Neverweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

Twoareasmustbeconsideredwhencheckingandservicing

thecuttingblade:thesailandthecuttingedge.Bothcutting

edgesandthesail,whichistheturnedupportionopposite

thecuttingedge,contributetoagoodquality-of-cut.The

sailisimportantbecauseitpullsgrassupstraight,thereby

producinganevencut.However,thesailwillgraduallywear

downduringoperation,andthisconditionisnormal.Asthe

sailwearsdown,thequality-of-cutwilldegradesomewhat,

althoughthecuttingedgesaresharp.Thecuttingedgeof

theblademustbesharpsothatthegrassiscutratherthan

torn.Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedgesto

correctthiscondition.

1.Raisethecuttingunittothehighestposition,shutthe

engineoff,andengagetheparkingbrake.Blockthe

cuttingunittopreventitfromaccidentallyfalling.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsoftheblade

meet(Figure28).Sincesandandabrasivematerialcan

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

machine.Ifwearisnoticed(Figure28),replacethe

blade;refertoRemovingtheCuttingBlade.

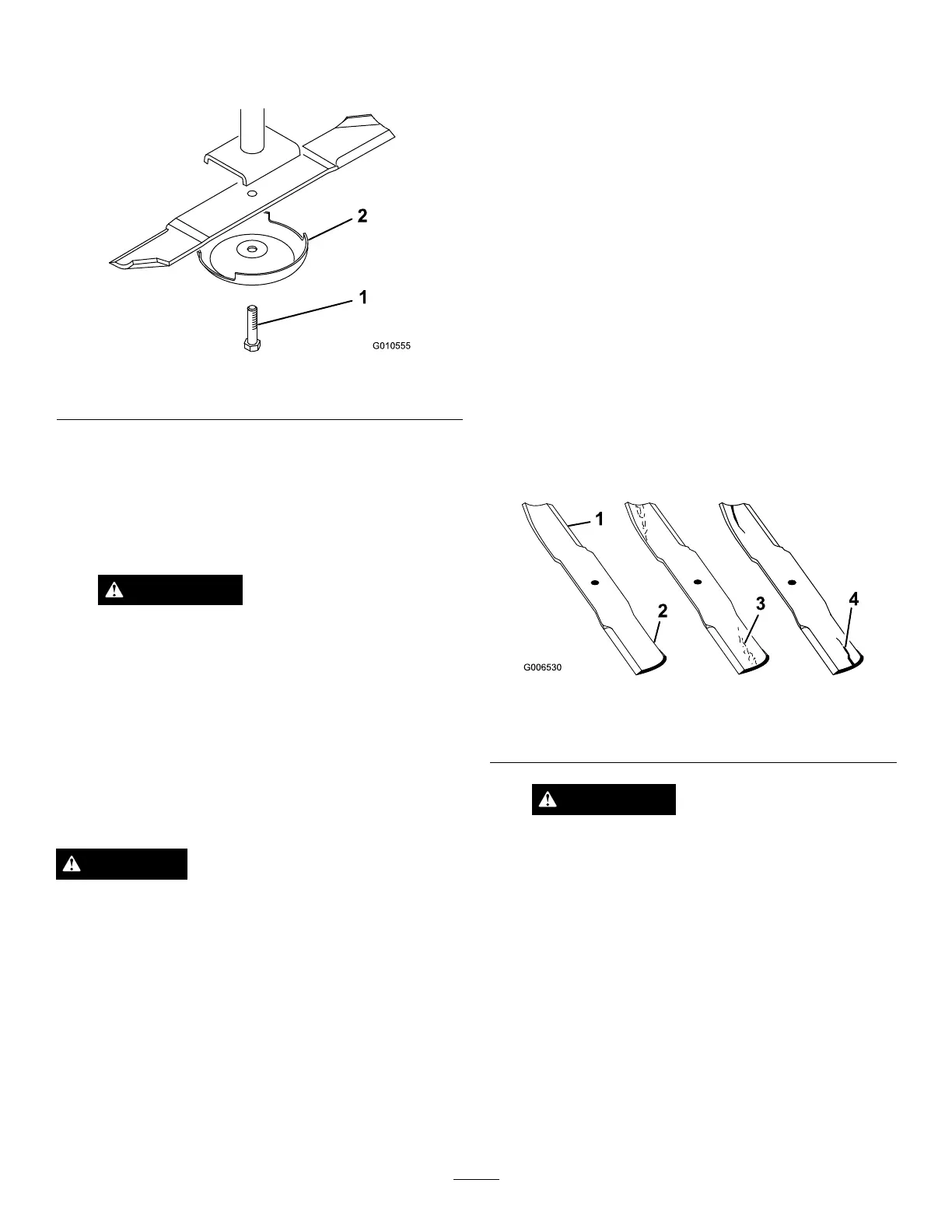

Figure28

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

WARNING

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

(Figure28).Eventually,apieceoftheblade

maybreakoffandbethrownfromunderthe

housing,possiblyresultinginseriousinjuryto

yourselforbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

3.Examinethecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopsideofthecuttingedgeandmaintainthe

21

Loading...

Loading...