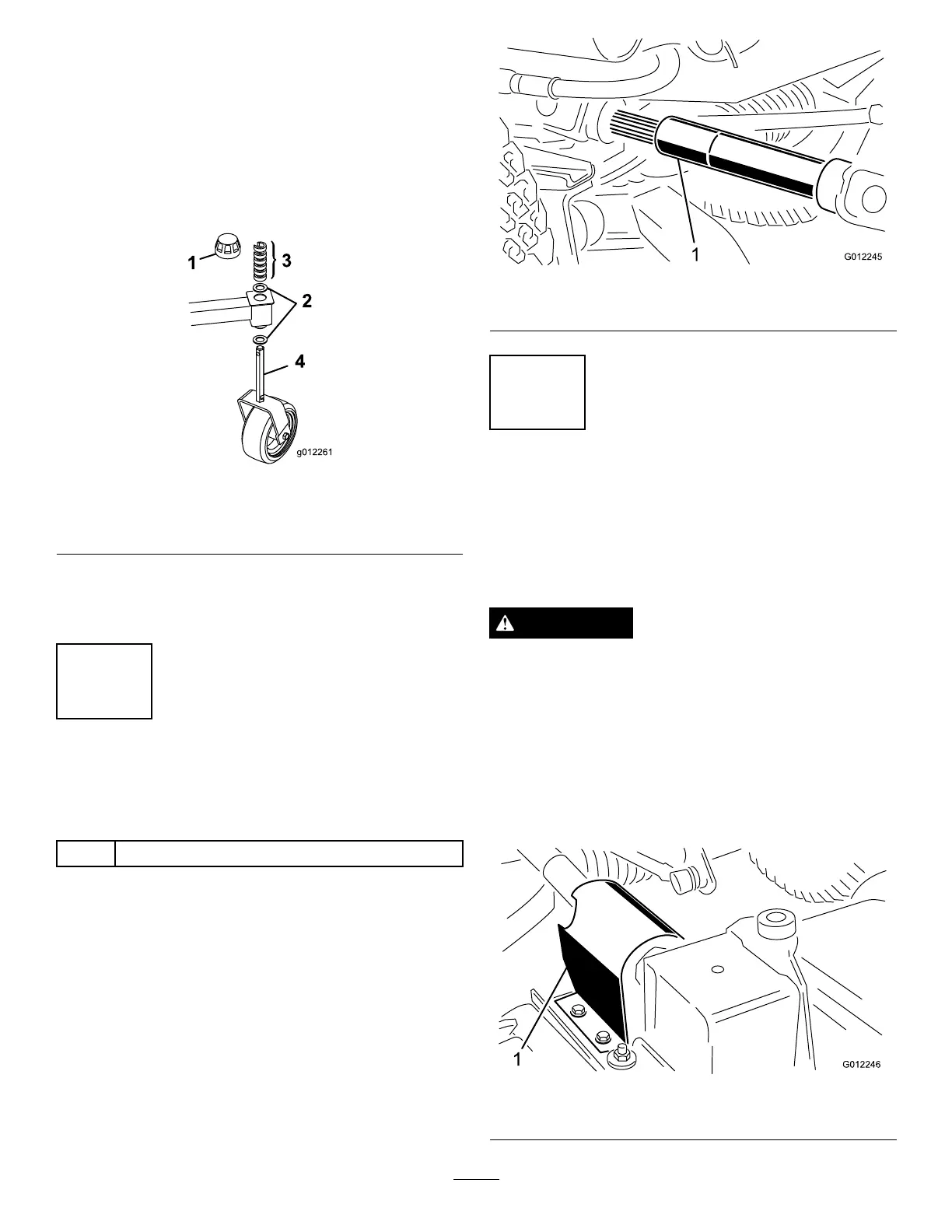

intheAdjustingtheHeightofcutsection.Slidea

thrustwasherontothespindle.Pushthelargecastor

spindlethroughthefrontcastorarmandthesmall

castorspindlethroughtherearcastorarm.Install

anotherthrustwasherandtheremainingspacersonto

thespindleandinstallthetensioningcaptosecurethe

assembly(Figure2&Figure3).

Important:Thethrustwashers,notthespacers,

mustcontactthetopandbottomofthecastorarm.

Figure3

1.Tensioningcap

3.Spacers

2.Thrustwashers

4.Small(rear)castorspindle

3.Ensurethatallfourcastorwheelsaresetatthesame

height-of-cut;thenrollthecuttingunitoffofthe

woodenpallet.

2

InstallingtheDriveShafttothe

TractionUnit

Partsneededforthisprocedure:

1

Driveshaft

Procedure

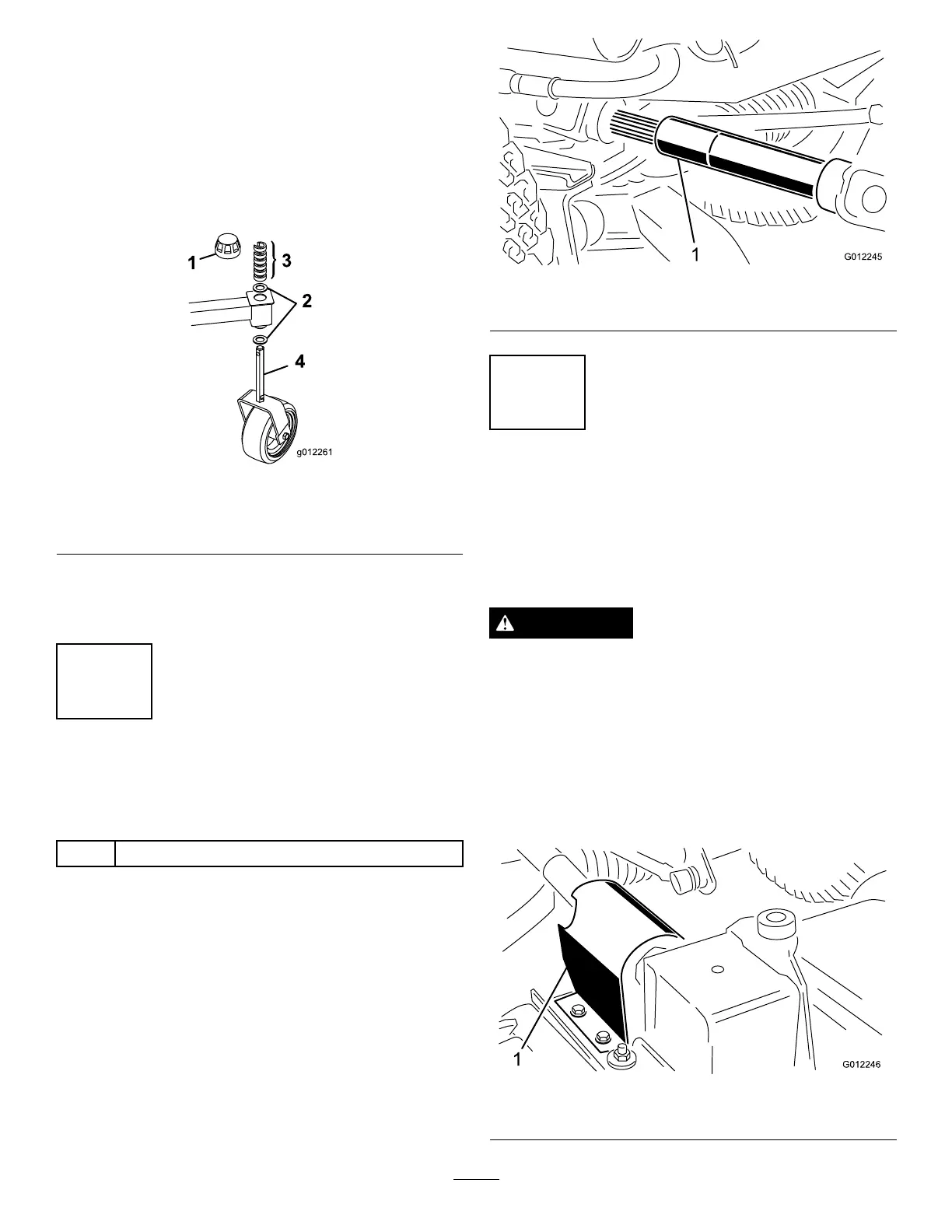

Slidethesmalleryokeendofthedriveshaftontothetraction

unitPTOshaftwhilealigningthemountingholes(Figure

4).Securethemwitharollpin.Donotinstallthefrontend

ofthedriveshaftatthistime.

Figure4

1.Driveshaft

3

ConnectingtheRight-Hand

PushArmtotheCuttingUnit

NoPartsRequired

Procedure

WARNING

Theright-handpusharmisspringloadedtoabout

45kg(100lb.).Suddenreleaseofthepusharm

couldcauseinjury.

Anotherpersonisneededtopushthearmdown

duringthisprocedure.

1.Removethe2self-tappingscrewssecuringthePTO

shieldtothetopofthecuttingunitgearboxmounting

plateandremovetheshield(Figure5).

Figure5

1.PTOshield

9

Loading...

Loading...