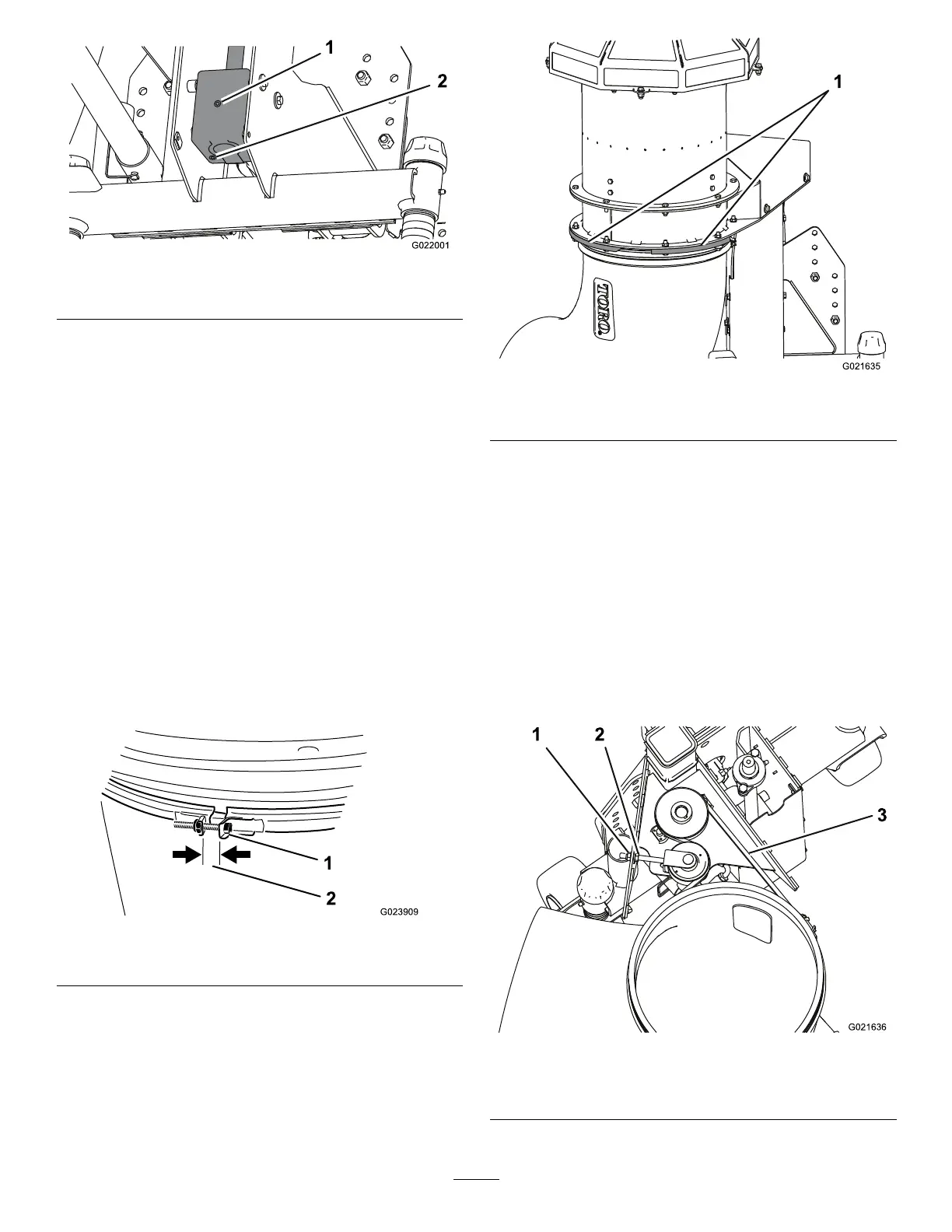

Figure25

1.Check/llplug

2.Drainplug

5.Checktheoilleveltomakesureitisuptotheplughole

inthegearbox.Ifthelubricantlevelislow ,addenough

SAE80-90weightgearlubetoraisetheleveluptothe

hole.Thegearboxcapacityis207ml(7oz).

6.Installthecheck/llplugtothegearbox.

7.Installthecover.

CheckingtheNozzle

ServiceInterval:Beforeeachuseordaily

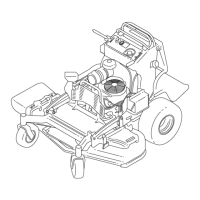

CheckingtheNozzleClamp

Checkthenozzleclamp(Figure26)dailytoassureitistight.

Ifthenozzleisdraggedoverobstaclesorthroughlowareasin

theterrainitcouldbeknockedloosefromtheclamp.Tighten

theclampfastenerstomaintainagapof1.3cm(.50inch).

Note:Thenozzlemustrotatefreelywhenmovedbyhand.

Figure26

1.Nozzleclamp

2.1.3cm(.50inch)gap

CleaningtheNozzleGuides

Checkandremoveanygrass,dirtordebrisbuilduparound

andinbetweenthenozzleguides(Figure27).Ifthenozzle

guidesarenotkeepfreeofdebris,thenozzlemaynotrotate

freelywhichcouldcausethemotortostall.

Figure27

1.Nozzleguides

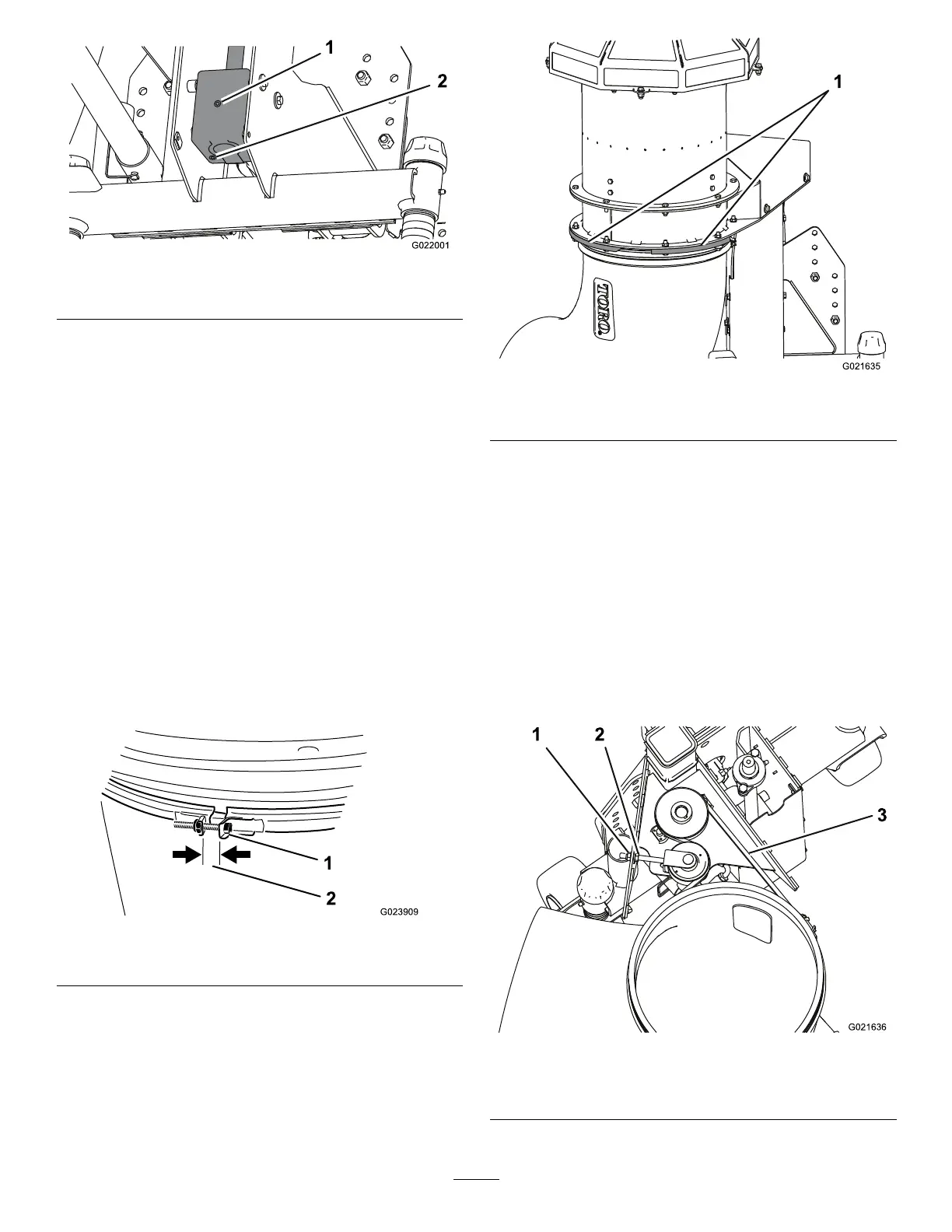

AdjustingtheNozzleBelt

ServiceInterval:Aftertherst8hours

Every50hours

Ifthebeltslipswhenchangingthedirectionofthenozzle,an

adjustmenttothebeltisrequired.

1.Checkthetensionbydepressingthebelt,atthecenter

ofthelongestspan,with30N-m.(22lb)offorce

(Figure28).Thebeltshoulddeect4.8mm(.19inch).

Ifthedeectionisincorrect,proceedtothenextstep.

Ifitiscorrect,continueoperation.

Figure28

1.Flangenut3.Depressbelthere

2.Hexnut

17

Loading...

Loading...