5.Movetheseattothefurthestforwardpositionto

exposetherearnuts.

6.Loosentherearnuts.

Note:Thenutsdonotneedtoberemoved.

7.Slidetheseatandseatplateforwardtoallowthefront

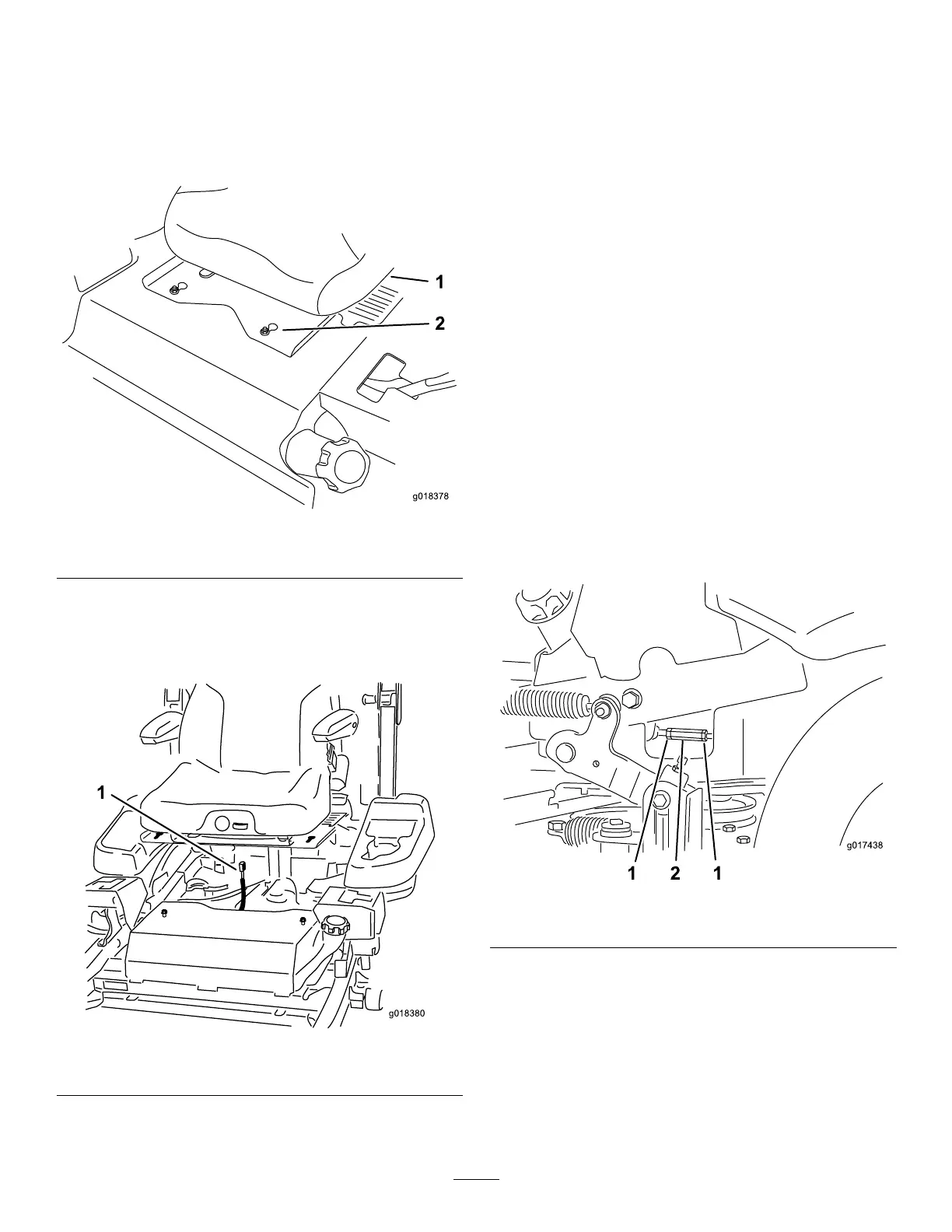

nutstogothroughthekeyhole(Figure63).

Figure63

1.Seat

2.Frontnutswithkeyhole

8.Loosentheboltsholdingtheseattothemachine,and

slidetheseatforwardintheslotstoremovetheseat.

9.Unplugtheharnessconnectorfromtheseatswitch

locatedundertheseat(Figure64).

Figure64

1.Harnessconnector

10.Temporarilyinstallajumperwireacrosstheterminals

intheconnectorofthemainwiringharness.

11.Starttheengine,runtheengineatfullthrottle,and

releasethebrake.

Important:Thebrakemustbeengaged,and

themotion-controlleversmustbeouttostartthe

engine.Theoperatordoesnothavetobeinthe

seatbecauseofthejumperwirebeingused.

12.Runtheunitatleast5minuteswiththedrivelevers

atfullforwardspeedtobringthehydraulicoilupto

operatingtemperature.

Note:Themotion-controlleverneedstobeinneutral

whilemakinganynecessaryadjustments.

13.Bringthemotion-controlleversintotheneutral

position.

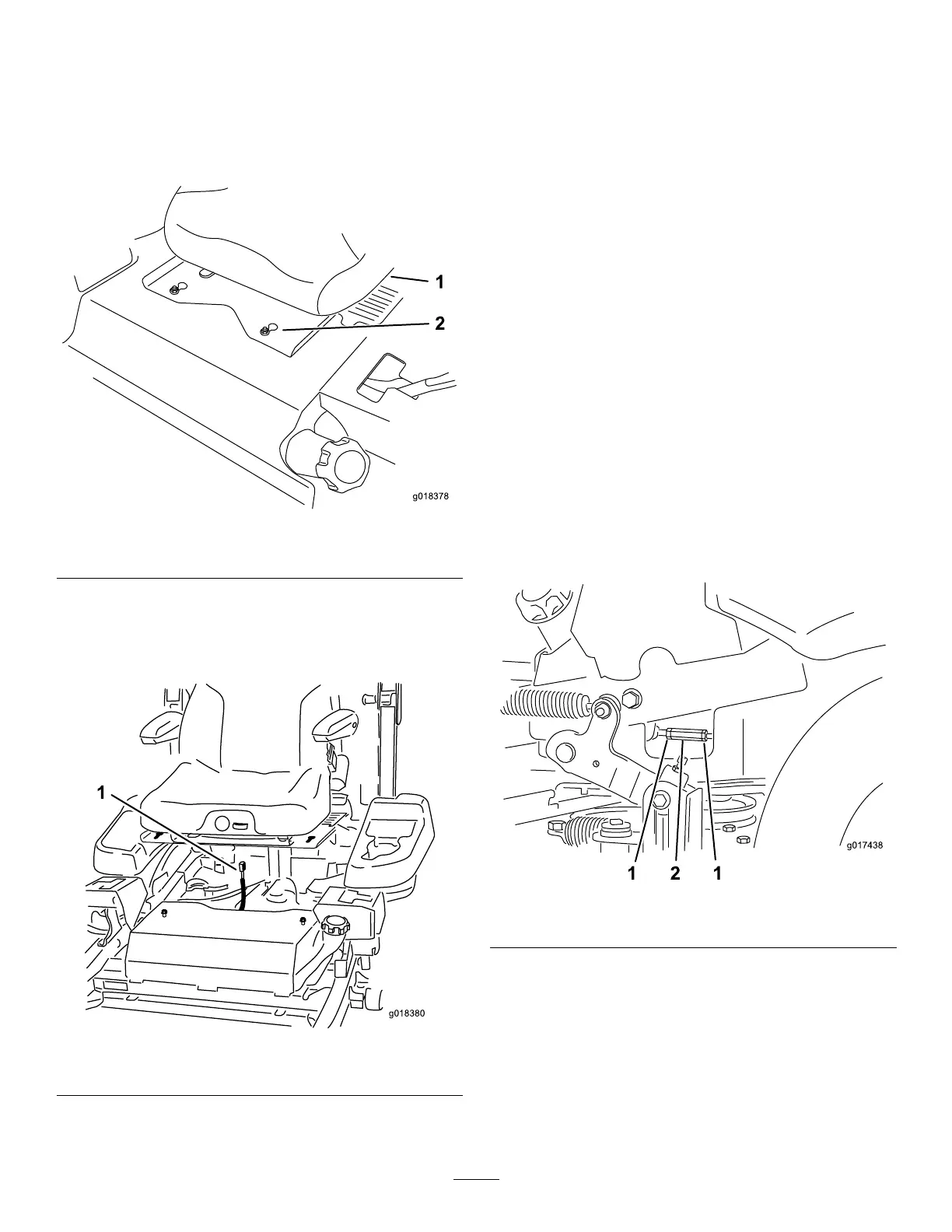

14.Adjustthepump-controlrodsbylooseningthe2jam

nutsandrotatingtheadjustmentnutintheappropriate

directionuntilthewheelsslightlycreepinreverse

(Figure65).

15.Movethemotion-controlleverstothereverseposition,

andwhileapplyingslightpressuretothelever,allow

thereverse-indicatorspringstobringtheleversback

toneutral.

Note:Thewheelsmuststopturningorslightlycreep

inreverse.

16.Tightenthe2jamnutsagainsttheadjustmentnut

(Figure65).

Figure65

1.Jamnut2.Adjustmentnut

17.Shutoffthemachine

18.Removethejumperwirefromthewireharness,and

plugtheconnectorintotheseatswitch.

19.Installtheseat.

20.Removethejackstands.

21.Raisethedeckandinstalltheheight-of-cutpin.

22.Ensurethatthemachinedoesnotcreepinneutralwith

theparkingbrakesdisengaged.

46

Loading...

Loading...