27

Installing the Blades

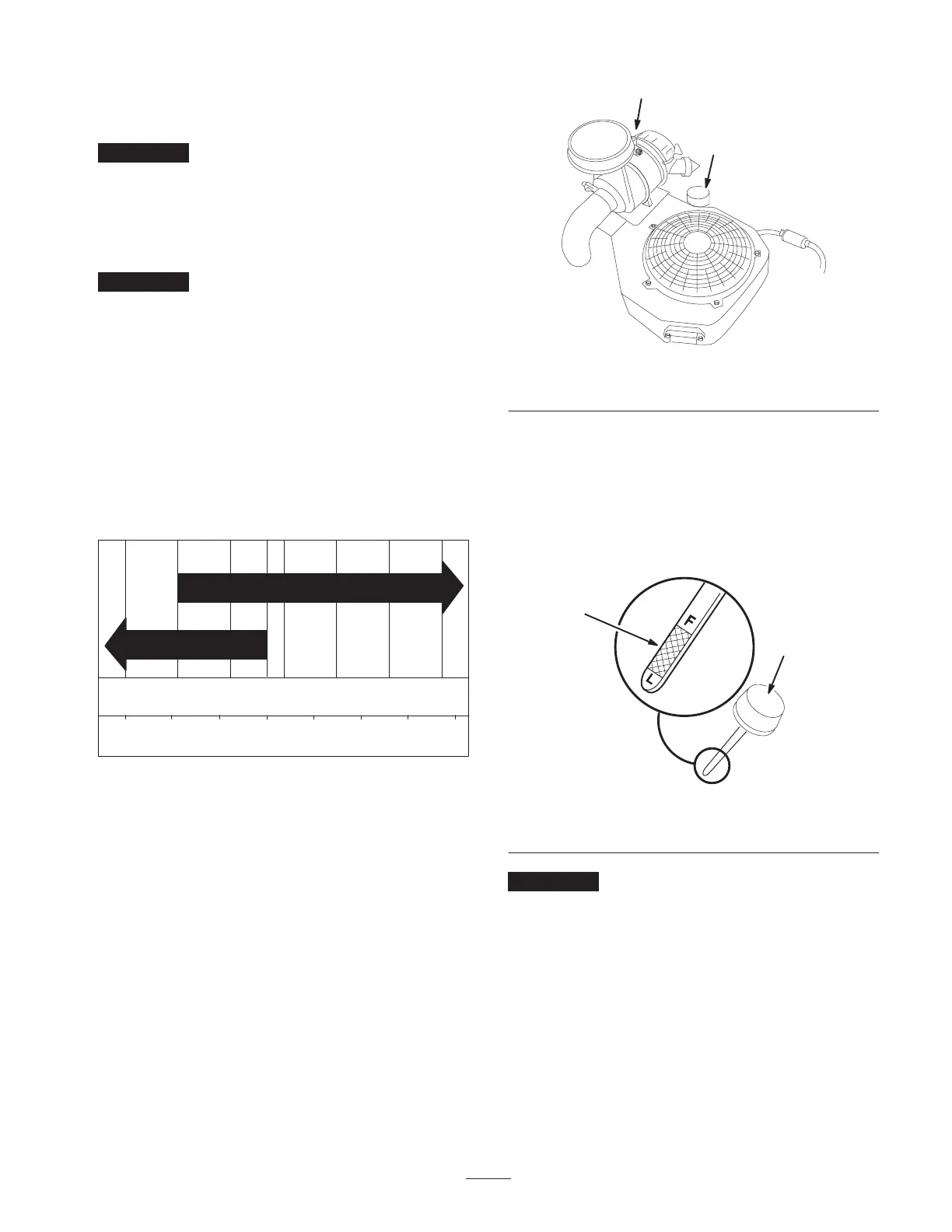

1. Install the blade onto the spindle shaft (Fig. 27).

Important The curved part of the blade must be

pointing upward toward the inside of the mower to ensure

proper cutting.

2. Install the flat washer, lock washer and blade bolt

(Fig. 27). Torque the blade bolt to 85–110 ft-lb

(115–150 N m).

Important Make sure blade is torqued to 85–110 ft-lb

(115–150 N m).

Engine Oil

Change the oil after every 100 operating hours.

Oil Type: Detergent oil (API service SG, SH, SJ, or

higher)

Crankcase Capacity: w/filter, 2.1 qt. (2 l)

Viscosity: See the table below.

F

–20 0 20

40 60

80 100

°

C

–30

°

–20 –10

01020

30 40

USE THESE SAE VISCOSITY OILS

32

10W–30

5W–20, 5W–30

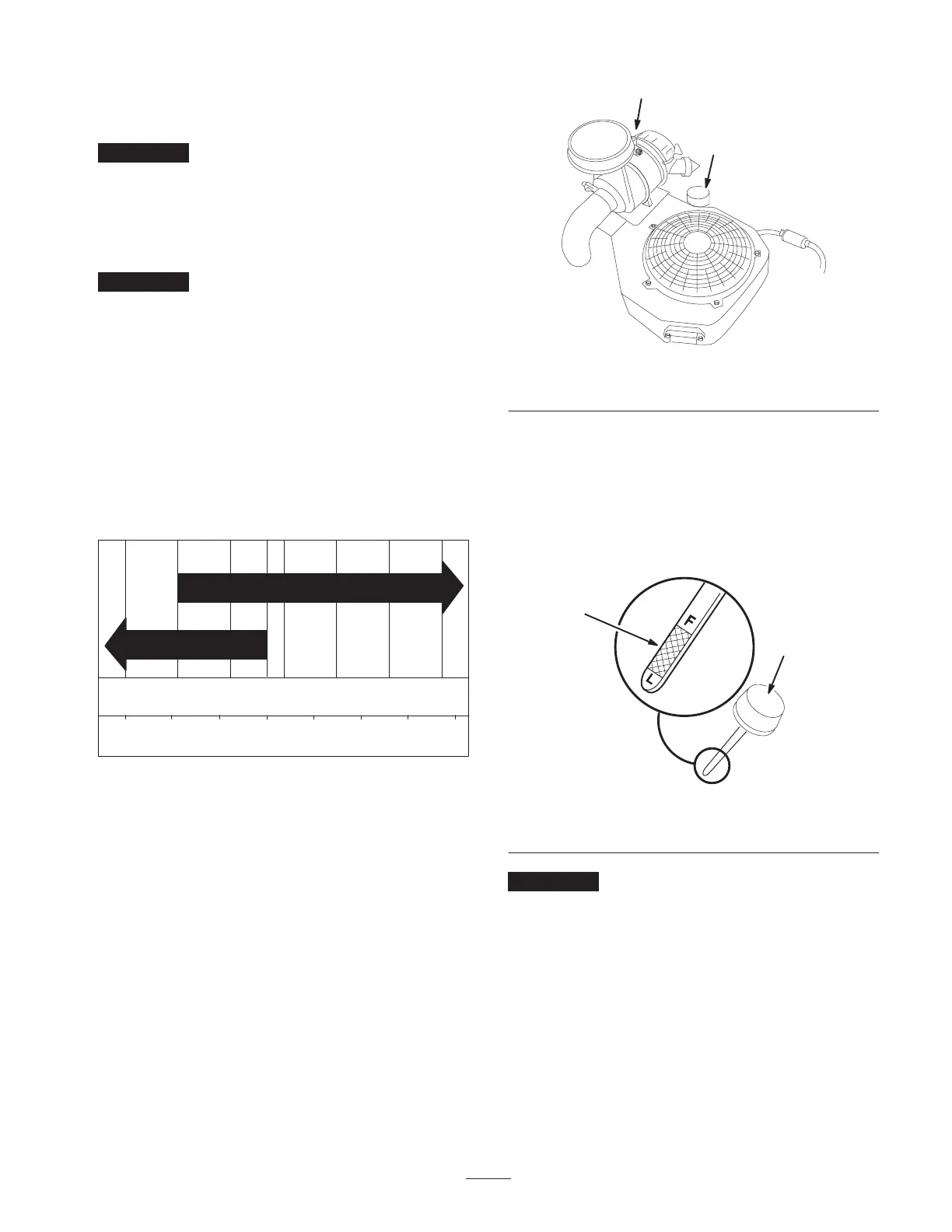

Checking the Oil Level

1. Park the machine on a level surface, disengage the

PTO, stop the engine, and remove the key.

2. Clean around the oil dipstick (Fig. 30) so that dirt

cannot fall into the filler hole and damage the engine.

m–6723

1

2

Figure 30

1. Oil fill/dipstick 2. Air cleaner

3. Unscrew the oil dipstick and wipe the metal end clean

(Fig. 30).

4. Slide the oil dipstick fully into the filler tube, but do

not thread it onto the tube. Pull the dipstick out and

look at the metal end (Fig. 31). If the oil level is low,

slowly pour only enough oil into the filler tube to raise

the level to, but not over, the “F” mark on the dipstick.

m–6726

1

2

Figure 31

1. Oil dipstick 2. Metal end

Important Do not overfill the crankcase with oil

because the engine may be damaged. Do not run engine

with oil below the low mark because the engine may be

damaged.

Changing and Draining the Oil

1. Start the engine and let it run for five minutes. This

warms the oil so that it drains better.

Loading...

Loading...