39

Charging the Battery

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks

and flames away from battery.

Warning

Important Always keep the battery fully charged

(1.265 specific gravity). This is especially important to

prevent battery damage when the temperature is below

32°F (0°C).

1. Remove the battery from the chassis; refer to

Removing the Battery, page 38.

2. Check the electrolyte level; refer to Checking

Electrolyte Level, page 37.

3. Make sure the filler caps are installed in battery.

Charge battery for 10 to 15 minutes at 25 to 30 amps

or 30 minutes at 4–6 amps.

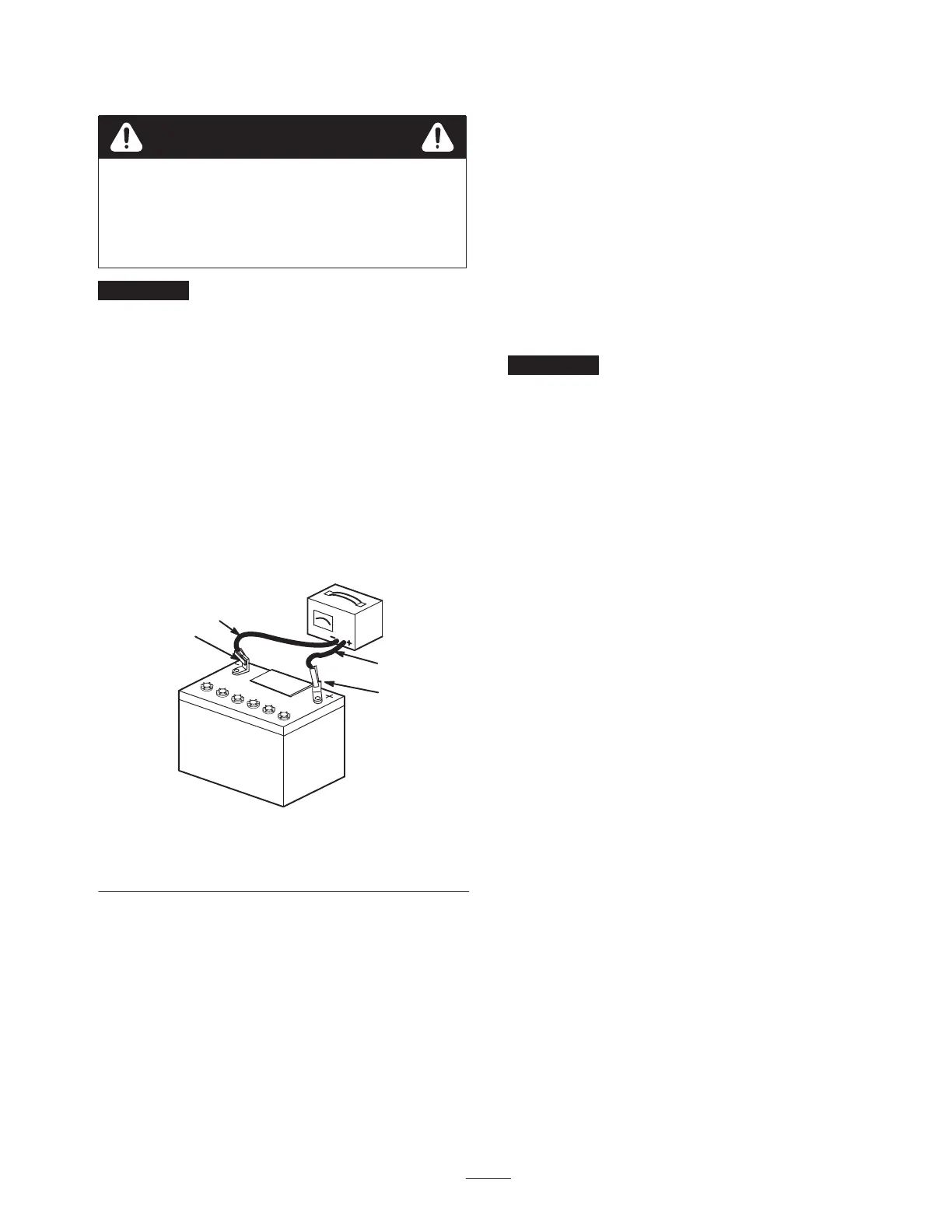

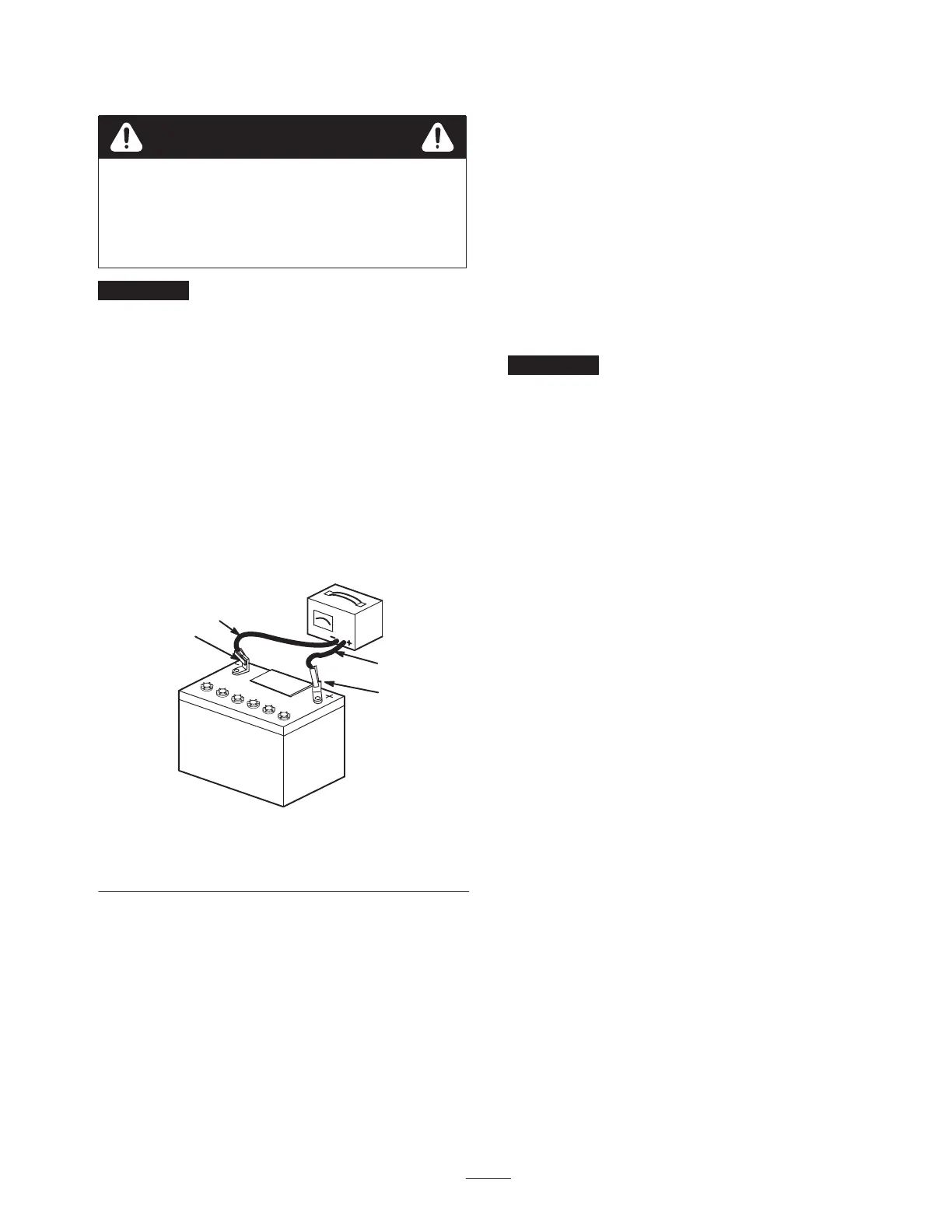

4. When the battery is fully charged, unplug the charger

from the electrical outlet, then disconnect the charger

leads from the battery posts (Fig. 51).

4

1

2

3

m–4970

Figure 51

1. Positive Battery Post

2. Negative Battery Post

3. Red (+) Charger Lead

4. Black (–) Charger Lead

5. Install the battery in the machine and connect the

battery cables; refer to Installing the Battery on

page 37.

Note: Do not run the machine with the battery

disconnected, electrical damage may occur.

Servicing the Hydraulic

System

Checking the Hydraulic Fluid

Check the hydraulic fluid level:

• Before the engine is first started.

• After the first 8 operating hours.

• After every 25 operating hours.

Fluid Type: Mobil 1 15W-50 synthetic motor oil or

equivalent synthetic oil.

Important Use oil specified or equivalent. Other

fluids could cause system damage.

Hydraulic System Oil Capacity: 67 oz. (2.0 l)

Note: There are two ways of checking the hydraulic oil.

One is when the oil is warm and one is when the oil is

cold. The baffle inside the tank has two levels depending

if the oil is warm or cold.

1. Position machine on a level surface and set the parking

brake.

2. Clean area around filler neck of hydraulic tank

(Fig. 52).

3. Remove the cap from the filler neck. Look inside to

check if there is fluid in the reservoir (Fig. 52).

4. If there is no fluid, add fluid to the reservoir until it

reaches the cold level of the baffle.

5. Run the machine at low idle for 15 minutes to allow

any air to purge out of the system and warm the fluid.

Refer to Starting and Stopping the Engine on page 17.

6. Recheck the fluid level while the fluid is warm. The

fluid should be between cold and hot.

7. If required, add fluid to the hydraulic tank.

Note: The fluid level should be to the top of the hot level

of the baffle, when the fluid is hot (Fig. 52).

8. Install cap on filler neck.

Loading...

Loading...