DriveSystem

Maintenance

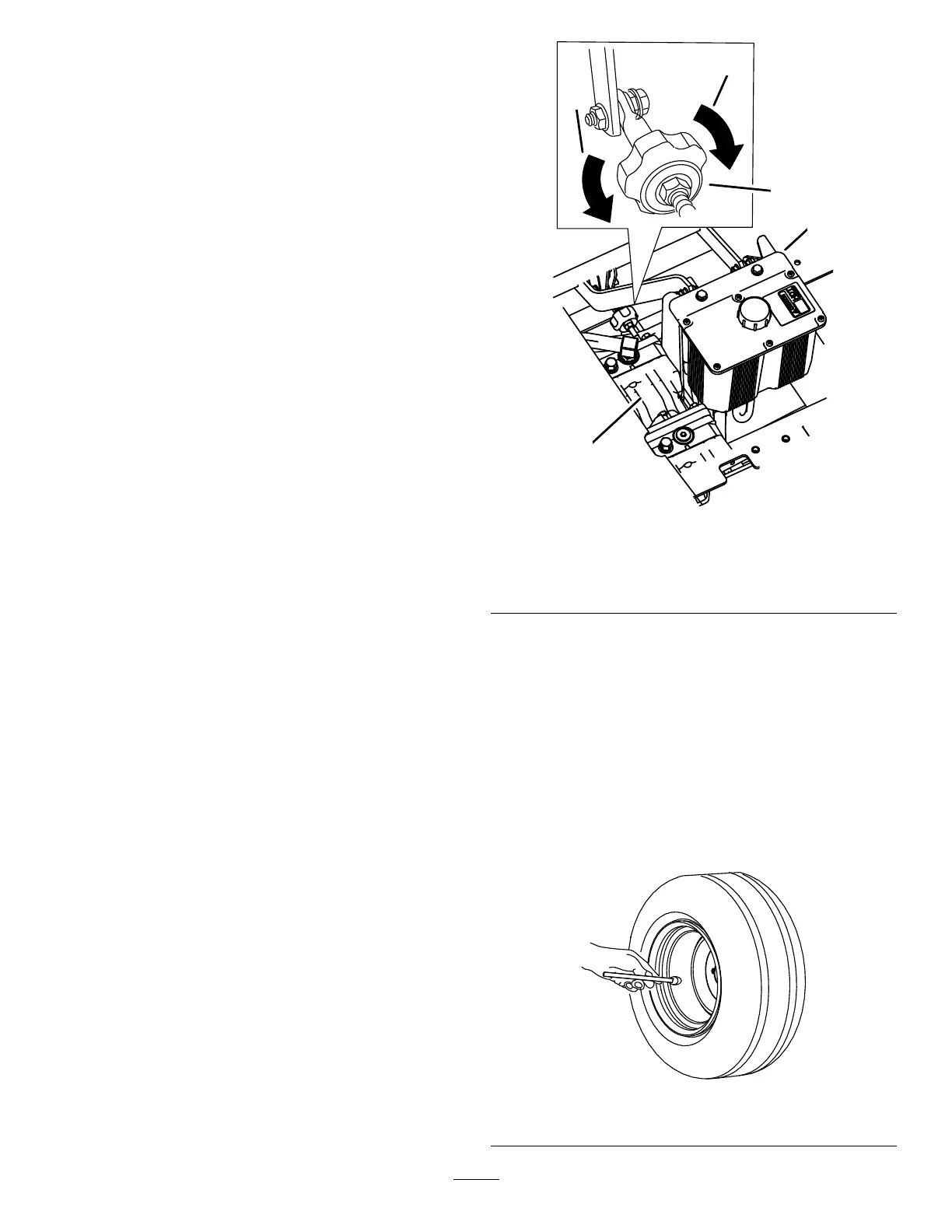

AdjustingtheTracking

Themachinehasaknobforadjustingthetracking

locatedundertheseat.

Important:Adjustthehandleneutralandhydraulic

pumpneutralbeforeadjustingthetracking.Refer

toAdjustingtheHandleNeutralinControlsSystem

Maintenance,page47andAdjustingtheHydraulic

PumpNeutralinHydraulicSystemMaintenance,

page48.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Unlatchtheseatandtilttheseatforwardtoaccess

thetrackingknob.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

4.Tomakethemachinegoright,turntheknobtowards

therightsideofthemachine.RefertoFigure46.

5.Tomakethemachinegoleft,turntheknobtowards

theleftsideofthemachine.RefertoFigure46.

6.Repeatadjustmentuntilthetrackingiscorrect.

Figure46

1.Trackingknob4.Turnthiswaytotrackright

2.Hydraulictank

5.Turnthiswaytotrackleft

3.Hydraulicpumps

CheckingtheTirePressure

ServiceInterval:Every50hours(ormonthly,which

evercomesrst).

Maintaintheairpressureinthereartiresat13psi(90

kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure47

39

Loading...

Loading...