adapter,thentightenthelteranadditional1/2turn

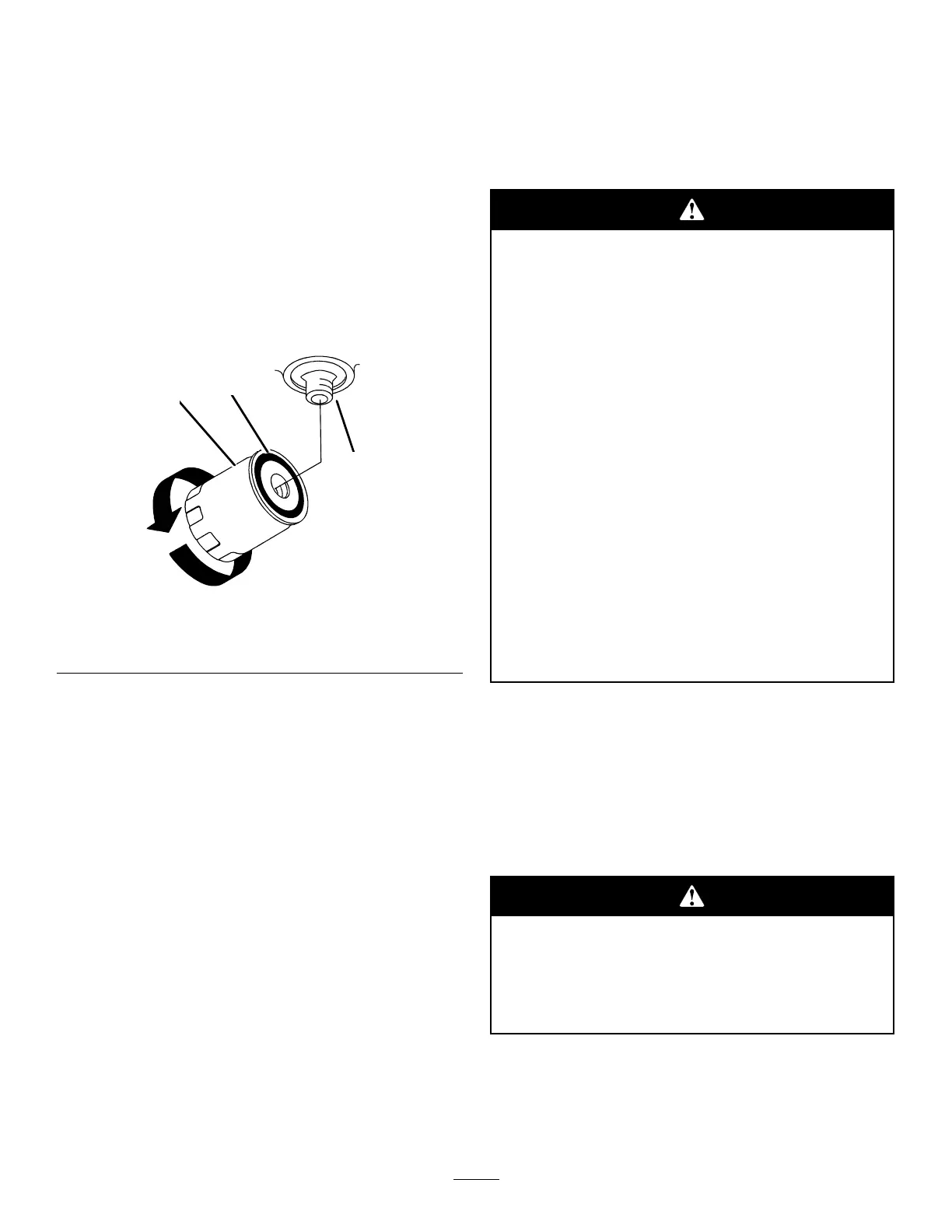

(Figure69).

10.Cleanupanyspilleduid.

11.Adduidtothecoldlevelofthebafeinthe

hydraulictank.

12.Starttheengineandletitrunforabouttwominutes

topurgeairfromthesystem.Stoptheengineand

checkforleaks.Ifoneorbothwheelswillnotdrive,

refertoBleedingHydraulicSystem.

13.Rechecktheuidlevelwhiletheuidiswarm.The

uidshouldbebetweencoldandhot.

14.Ifrequired,adduidtothehydraulictank.Donot

overll.

Figure69

1.Hydrauliclter

3.Adapter

2.Gasket

BleedingtheHydraulicSystem

Thetractionsystemisselfbleeding,however,itmaybe

necessarytobleedthesystemifuidischangedorafter

workisperformedonthesystem.

1.Raiserearofthemachinesowheelsareoffthe

groundandsupportwithjackstands.

2.Starttheengineandrunatlowidlespeed.Engage

theleverandtractionononesideandspinthewheel

byhand.

3.Whenthewheelbeginstospinonitsown,keepit

engageduntilwheeldrivessmoothly.(minimum

2minutes)

4.Checkhydraulicuidlevelandaddasrequiredto

maintainproperlevel.

5.Repeatthisprocedureontheoppositewheel.

CheckingtheHydraulicHoses

ServiceInterval:Every100hours

Afterevery100operatinghours,checkthehydraulic

hosesforleaks,loosettings,kinkedlines,loose

mountingsupports,wear,weatherandchemical

deterioration.Makenecessaryrepairsbeforeoperating.

Note:Keepareasaroundthehydraulicsystemclean

fromgrassanddebrisbuildup.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskin

itmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistypeof

injury.Gangrenemayresultifthisisnot

done.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretohydraulicsystem.

SettingtheHydraulicPump

NeutralPosition

Note:Adjustthehandleneutralrst.Thatneedstobe

correctbeforethefollowingadjustmentcanbemade.

Thisadjustmentmustbemadewithdrivewheelsturning.

Mechanicalorhydraulicjacksmayfailto

supportmachineandcauseaseriousinjury.

•Usejackstandwhensupportingmachine.

•Donotusehydraulicjacks.

50

Loading...

Loading...