Figure66

1.Cap3.Colduidlevel-full

2.Bafe4.Hotuidlevel-full

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskin

itmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistypeof

injury.Gangrenemayresultifthisisnot

done.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretohydraulicsystem.

ReplacingtheHydraulicFilterandOil

ServiceInterval:Aftertherst25hours—Changethe

hydrauliclterandcheckhydraulic

oillevel.

Yearly—Changethehydrauliclter

andoil.

Usesummerlterabove32°F(0°C)

Usewinterlterbelow32°F(0°C)

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Important:Donotsubstituteautomotiveoil

lterorseverehydraulicsystemdamagemay

result.

3.Placedrainpanunderlter,removetheoldlter

andwipethelteradaptergasketsurfaceclean

(Figure67).

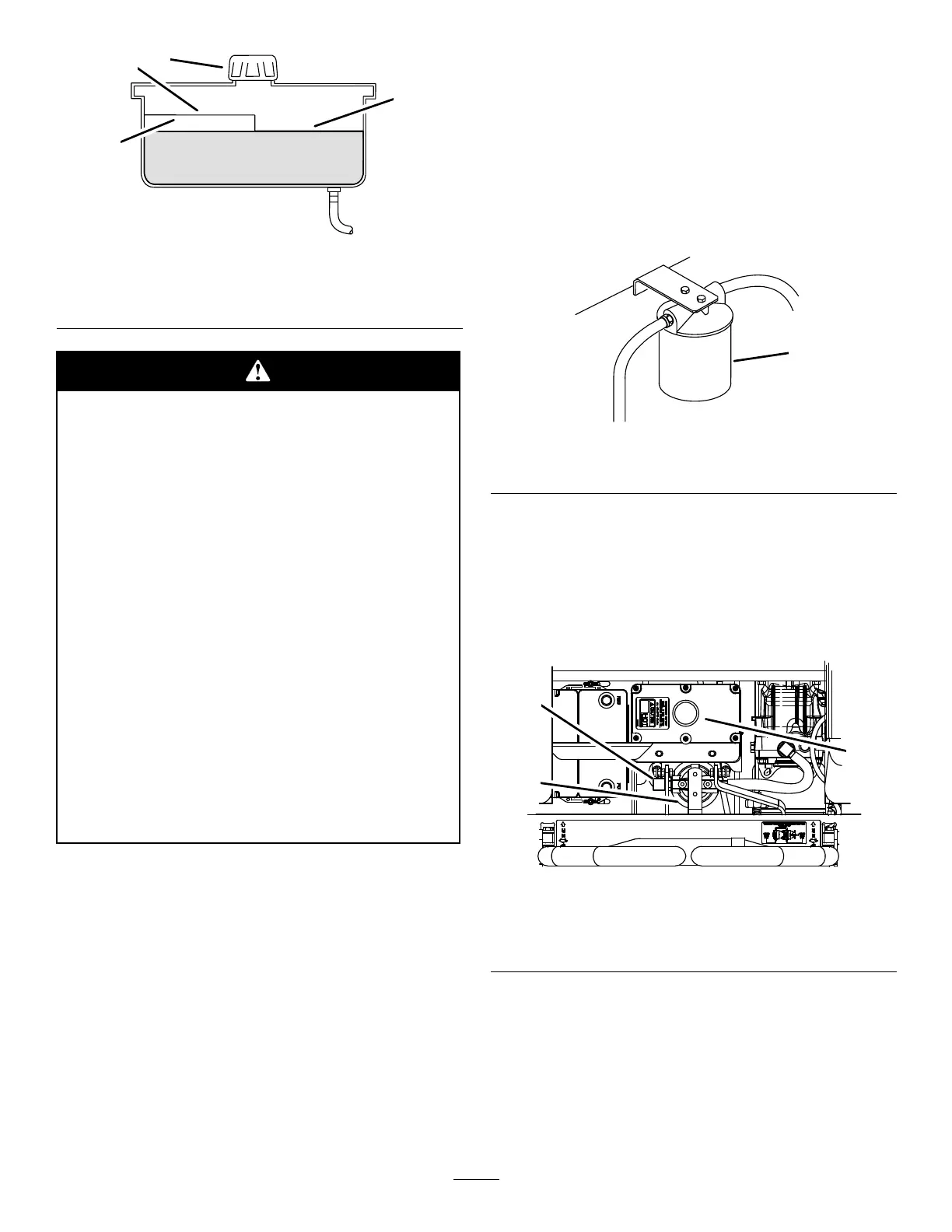

Figure67

1.Hydrauliclter

4.Removetherighthandhydrauliclinethatcomesinto

theadapter(Figure68).

5.Allowtheoiltodrainoutofthesystemintothe

drainpan.

6.Installtherighthandhydrauliclinetotheadapter

(Figure68).

Figure68

1.Righthandhydraulicline3.Hydraulictank

2.Hydrauliclter

7.Applyathincoattotherubbergasketonthe

replacementlter(Figure69).

8.Installthereplacementhydrauliclterontothelter

adapter.Donottighten.

9.Fillthehydraulictankwithhydraulicuiduntilthe

uidoverowsthelterandthenturntheoillter

clockwiseuntiltherubbergasketcontactsthelter

49

Loading...

Loading...