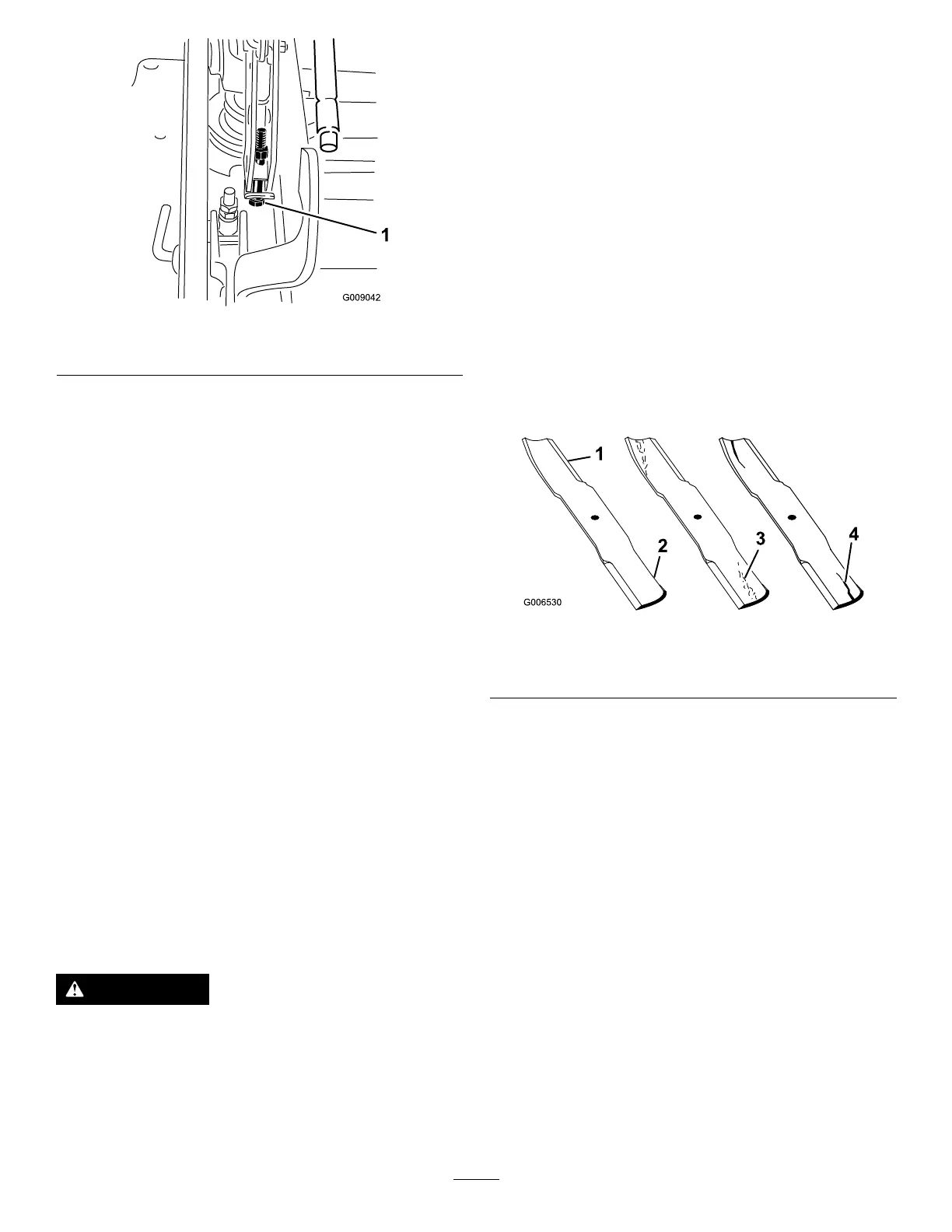

Figure88

1.Singlepointadjustmentbolt

11.Tightenthe2boltsatthebottomoftheheight-of-cut

plate(Figure87).

Note:Inmostconditions,ensuretheback,bladetipis

adjusted6.4mm(1/4inch)higherthanthefront.

12.Torquethe2boltsto37to45N∙m(27to33ft-lb).

13.Onbothsidesofthedeck,measurefromthelevel

surfacetothebacktipoftheblade(positionB)as

showninFigure85.

Note:Themeasurementshouldread8.3cm(3-1/4

inches)

14.Fine-tunethescrewadjusterbyturningittoget8.3

mm(3-1/4inches)height(Figure86).

Note:Toincreasetheheight,turntheadjustmentnut

clockwise;todecrease,turncounterclockwise.

15.Measureuntilall4sidesarethecorrectheight.

16.Tightenallthenutsonthedeck-lift-armassemblies.

ServicingtheCuttingBlades

Important:Therightbladeonthismowerdeckis

counter-rotatingandusesaleftthreadedbladebolt.Use

Figure92forthecorrectplacementofthemowerblades.

Maintainsharpbladesthroughoutthecuttingseasonbecause

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowthandincreasesthechanceofdisease.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownatyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladesperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch(PTO),andsettheparkingbrake.

2.TurntheignitionkeytoOFF.Removethekey,and

disconnectthesparkplugwiresfromthesparkplugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure89).

2.Iftheedgesarenotsharporhavenicks,removeand

sharpentheblade;refertoRemovingtheBlades(page

60)andSharpeningtheBlades(page61).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforminginthis

area,immediatelyinstallanewblade(Figure89).

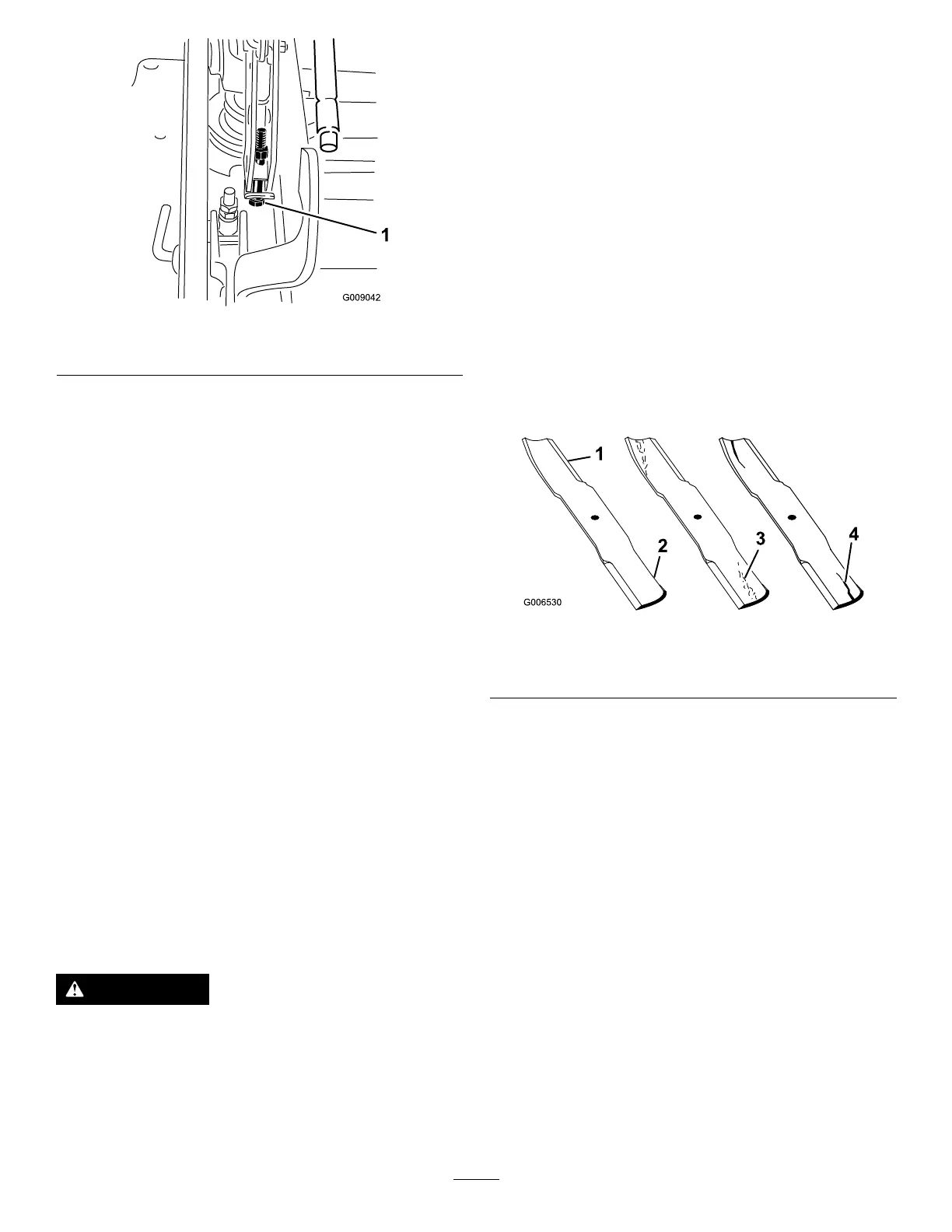

Figure89

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

CheckingforBentBlades

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Rotatethebladesuntiltheendsfaceforwardand

backward(Figure90).

4.Measurefromalevelsurfacetothecuttingedge,

positionA,oftheblades(Figure90).Notethis

dimension.

59

Loading...

Loading...