RemovingtheClutchShim

1.Shutofftheengine,waitforallmovingpartstostop,

andremovethekey.

2.Engagetheparkingbrakeandwaitformachinetocool

completely.

3.Usinganaircompressor,blowoutanydebrisunderthe

brakepoleandaroundthebrakespacers.

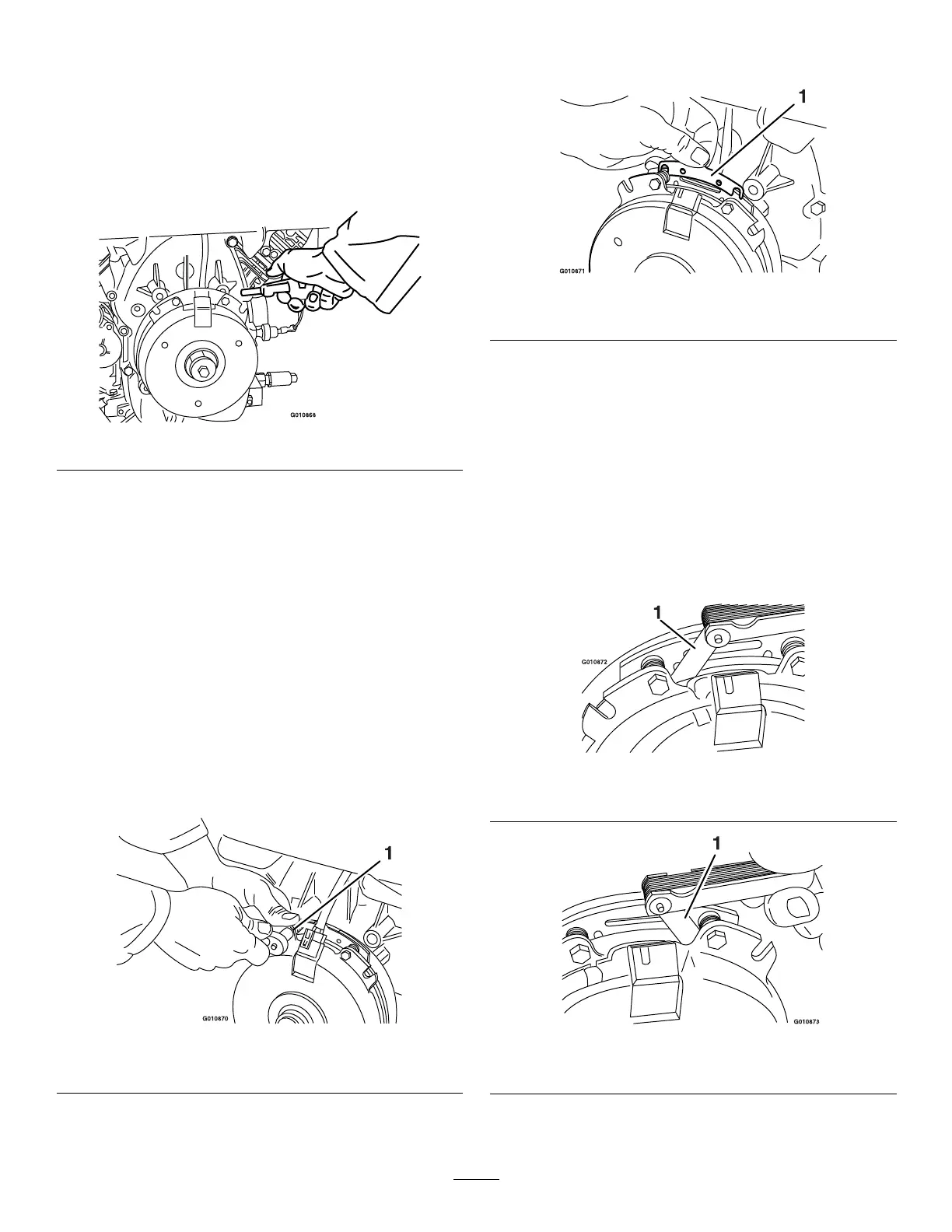

Figure70

4.Checktheconditionofthewire-harnessleads,

connectors,andterminals.Cleanorrepairthemas

necessary.

5.Verifythat12Vispresentattheclutchconnector

whentheyouengagetheblade-controlswitch(PTO).

6.Measurethegapbetweentherotorandarmature.If

thegapisgreaterthan1mm(0.04inch),proceedwith

thefollowingsteps:

A.Loosenbothbrakemountingbolts1/2to1full

turnasshowninFigure71.

Note:Donotremovethebrakepolefromthe

eldshell/armature.Thebrakepolehasworn

tomatchthearmatureandneedstocontinueto

matchafteryouremovetheshimtoensurethe

properbraketorque.

Figure71

1.Brake-mountingbolt

B.Usingneedle-nosepliers,orbyhand,removethe

shim.

Note:Donotdiscardtheshimuntilyouconrm

thattheclutchfunctionsproperly.

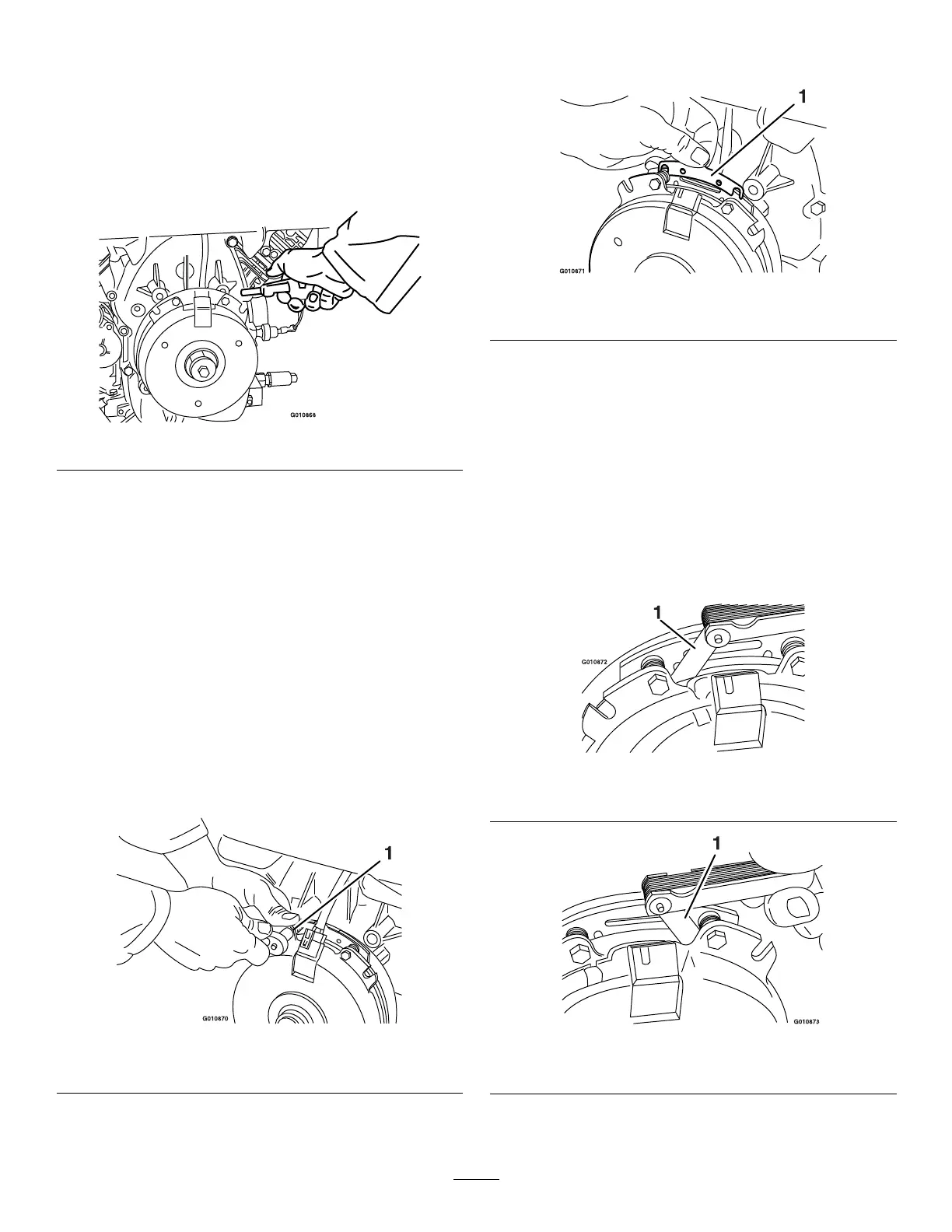

Figure72

1.Shim

C.Usingapneumaticline,blowoutanydebrisunder

thebrakepoleandaroundthebrakespacers.

D.Torqueeachbolt(M6x1)to12.3to13.7N∙m

(9.5to10.5ft-lb).

E.Usinga0.010inchthick-feelergauge,verifythat

agapispresentbetweentherotorandarmature

faceonbothsidesofthebrakepoleasshownin

Figure73andFigure74.

Note:Duetothewaytherotorandarmature

faceswear(peaksandvalleys),itissometimes

difculttomeasurethetruegap.

Figure73

1.Feelergauge

Figure74

1.Feelergauge

50

Loading...

Loading...