AdjustingtheBedknifetotheReel

Usethisprocedureduringinitialcutting-unitsetupand

aftergrinding,backlapping,ordisassemblingthereel.

Thisisnotadailyadjustment.

Note:Thisprocedurecanbeperformedwiththe

cuttingunitinstalledtothetractionunit.

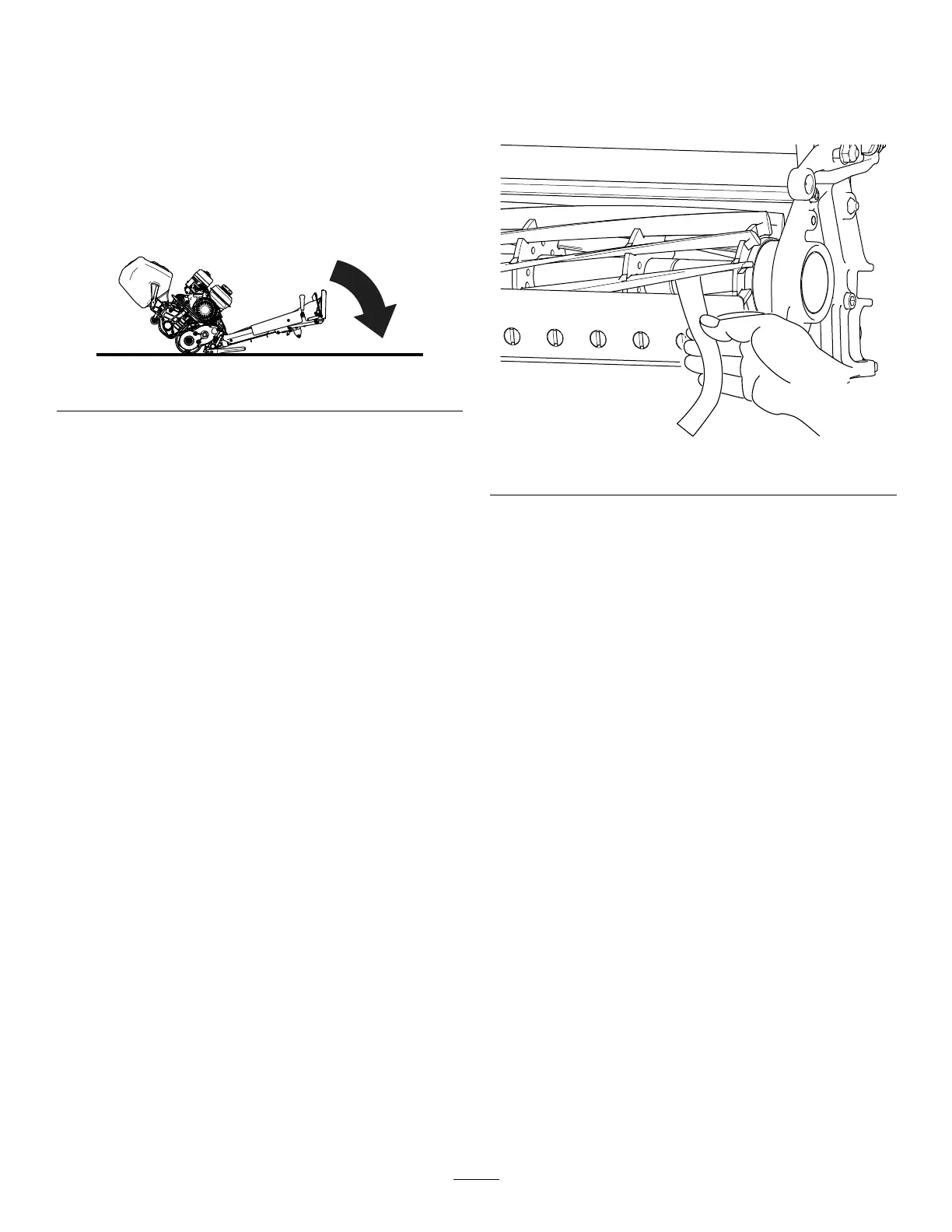

1.Shutoffthetraction-unitengine.

2.Accessthecuttingunitbyloweringthe

traction-unithandletotheground(Figure9).

g276933

Figure9

3.Rotatethereelsothat1ofthebladescrosses

thebedknifeedgebetweentherstandsecond

bedknifescrewheadslocatedontherightside

ofthecuttingunit.

4.Makeanidentifyingmarkonthebladewhereit

crossesthebedknifeedge.

Note:Thiswillmakelateradjustmentseasier.

5.Inserta0.05mm(0.002inch)shimbetweenthe

bladeandthebedknifeedgeatthepointmarked

instep4.

6.Turntherightbedbaradjustingscrew(Figure8)

untilyoufeellightpressureontheshimwhen

slidingitside-to-side.Removetheshim.

7.Fortheleftsideofthecuttingunit,slowlyrotate

thereelsothattheclosestbladecrossesthe

bedknifeedgebetweentherstandsecond

screwheads.

8.Repeatsteps4through6fortheleftsideofthe

cuttingunitandleftbedbaradjustingscrew.

9.Repeatsteps5and6untilthereislightpressure

atthecontactpointsonboththeleftandright

sidesofthecuttingunit.

10.Toobtainlightcontactbetweenthereeland

bedknife,turneachbedbaradjustingscrew

clockwise3clicks.

Note:Eachclickonthebedbaradjustingscrew

movesthebedknife0.018mm(0.0007inches).

Donotovertightentheadjustingscrews.

Turningtheadjustingscrewclockwisemoves

thebedknifeedgeclosertothereel.Turningthe

adjustingscrewcounterclockwisemovesthe

bedknifeedgeawayfromthereel.

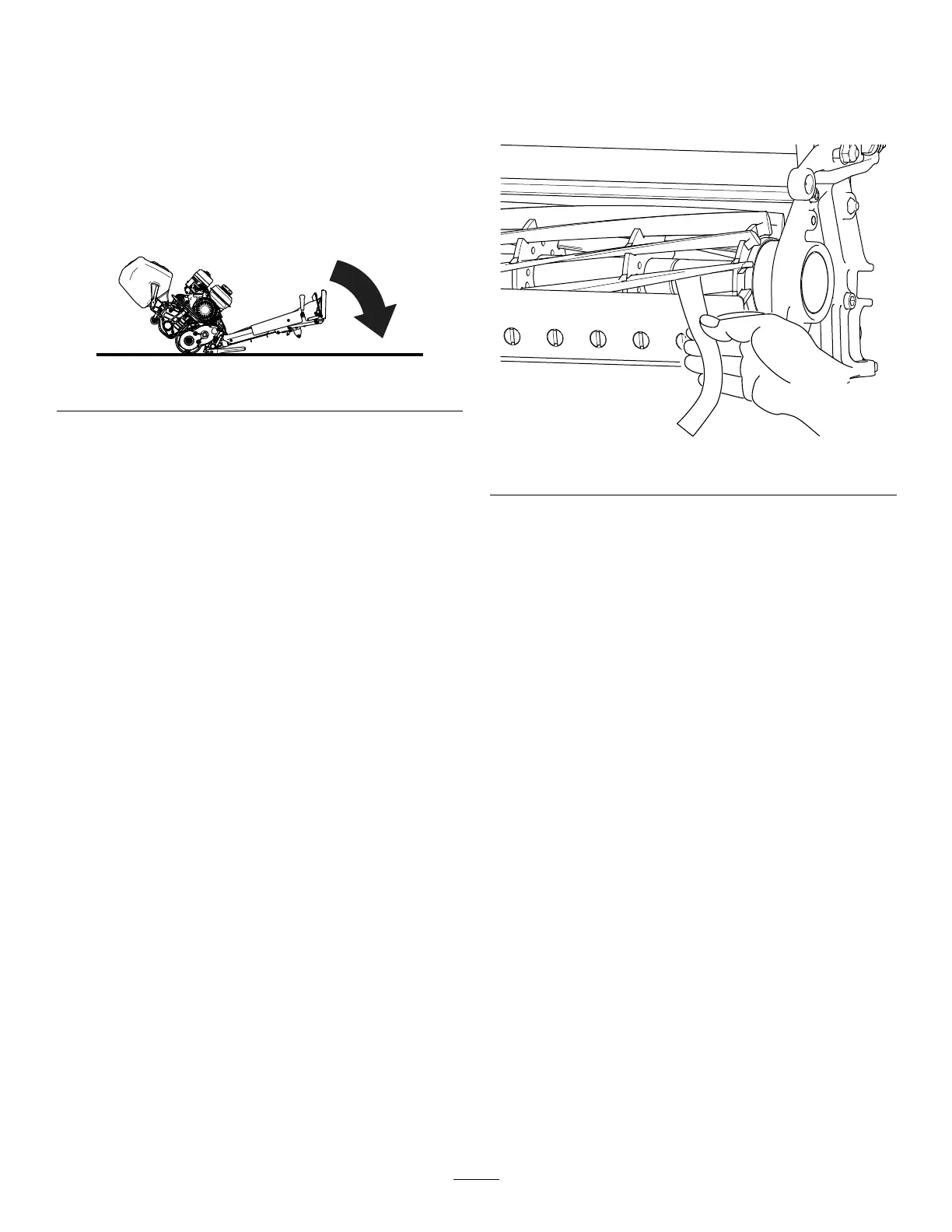

11.Insertalongstripofcuttingperformancepaper

(ToroPartNo.125-5610)betweenthereeland

bedknife,perpendiculartothebedknife(Figure

10),thenslowlyrotatethereelforward;itshould

cutthepaper;ifnot,turneachbedbaradjusting

screwclockwise1clicksandrepeatthisstep

untilitcutsthepaper.

g276305

Figure10

Note:Ifexcessivecontact/reeldragisevident,

backlap,refacethefrontofthebedknife,orgrind

thecuttingunittoachievethesharpedgesneeded

forprecisioncutting(RefertotheToroManualfor

SharpeningReelandRotaryMowers,FormNo.

09168SL).

8

Loading...

Loading...