BeltMaintenance

Servicingthe12V

AlternatorBelt

ServiceInterval:Aftertherst50hours

Every250hours

Refertotheengineowner'smanual(includedwiththe

machine)fortheservicingprocedure.

Servicingthe24V

AlternatorBeltandAC

CompressorBelt

ServiceInterval:Aftertherst10hours

Every1,000hours

TheACcompressorand24Valternatorbeltusesa

spring-loadedtensionerthatispre-setatthefactory.

RefertotheToroServiceManualfortheservicing

procedure.

ReplacingtheBlade-Drive

Belts

ServiceInterval:Every50hours—Inspectthe

blade-drivebelts.

Every1,000hours—Replacetheblade-drive

belts.

Theblade-drivebelt,tensionedbythespring-loaded

idlerpulley,isverydurable.However,aftermany

hoursofuse,thebeltwillshowsignsofwear.Signs

ofawornbeltaresquealingwhenthebeltisrotating,

bladesslippingwhencuttinggrass,frayededges,

burnmarks,andcracks.Replacethebeltifanyof

thesesignsoccur.

ReplacingtheFrontCutting-Unit

Belts

1.Lowerthecuttingunittotheoor.

2.Removethebeltcoversfromthetopofthe

cuttingunitandsetthecoversaside.

3.Onthefrontdeck,centerposition,loosenthe

jamnutsontheidlerpulleystopscrewand

threadthestopscrewintothebracket(Figure

124).

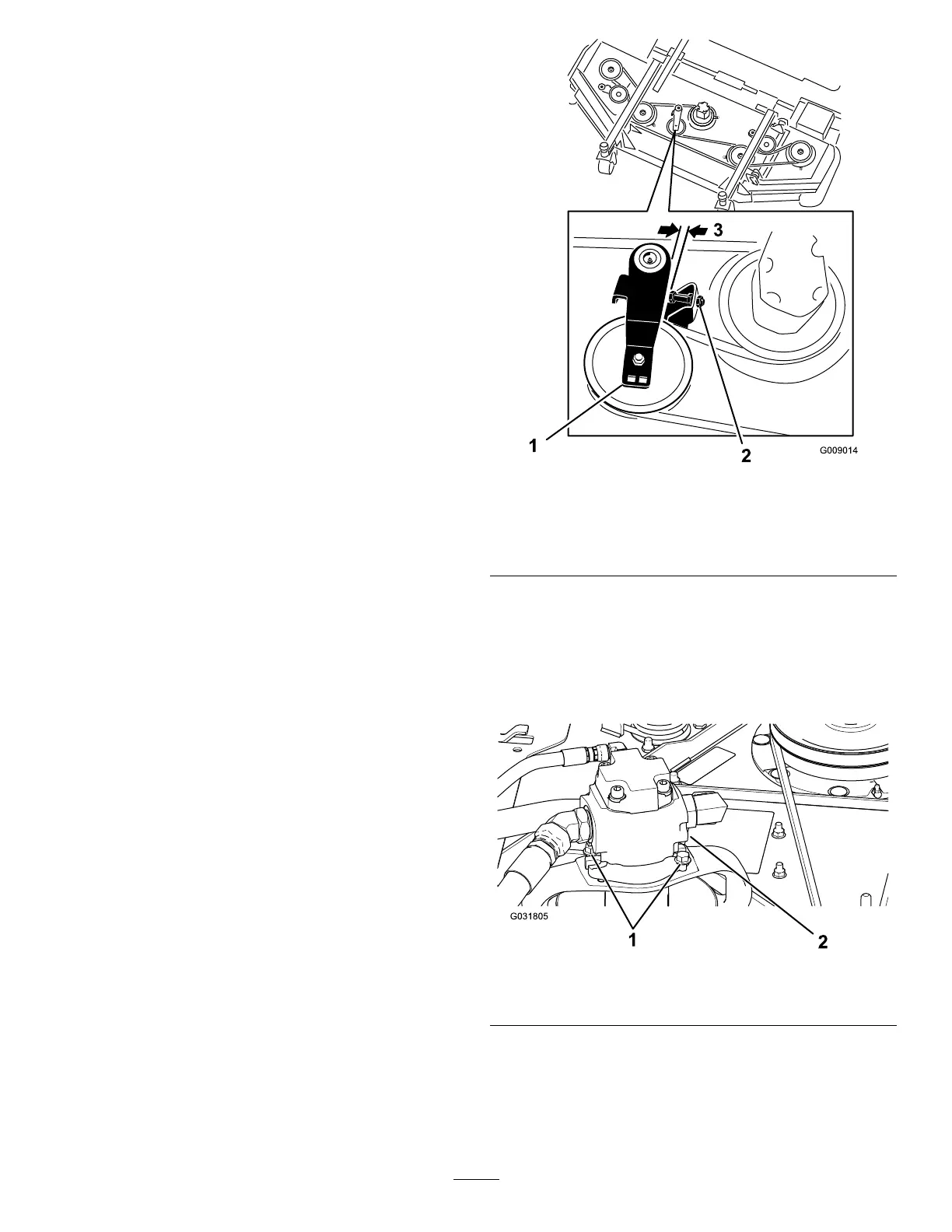

g009014

Figure124

1.Idlerpulley

3.2.5mmto4mm(0.10to

0.16inch)

2.Idlerstopscrew

4.Usingaratchetwrenchorsimilartool,move

eachwing-deckidlerpulleyawayfromthedrive

belttoreleasethebelttensionandallowthebelt

toslipoffthewing-deckpulley(Figure124).

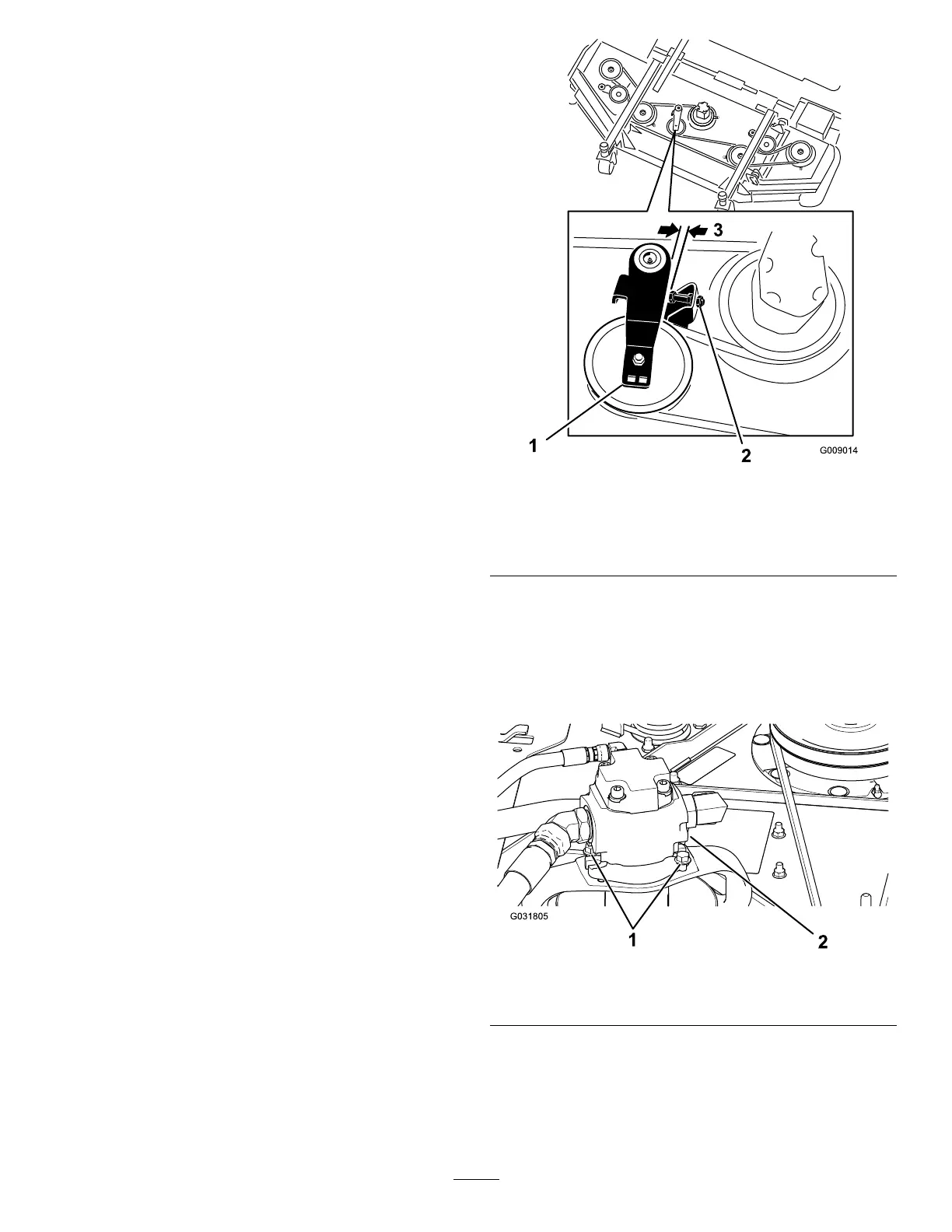

5.Removetheboltssecuringthehydraulicmotor

tothecuttingunit(Figure125).

g031805

Figure125

1.Mountingbolts2.Hydraulicmotor

6.Liftthemotoroffthecuttingunitandlayitontop

ofthecuttingunit.

7.Removetheoldbeltfromaroundthespindle

pulleysandidlerpulley.

84

Loading...

Loading...