MaintenanceService

Interval

MaintenanceProcedure

Every300hours

•Checkandadjustthevalveclearance.ContactanAuthorizedServiceDealer.

Beforestorage

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Shutofftheengineandremovethekeyfromtheswitchbeforeyouperformanymaintenance.

Pre-Maintenance

Procedures

RaisingtheMachine

Usejackstandstosupportthemachinewhenyou

raiseit.

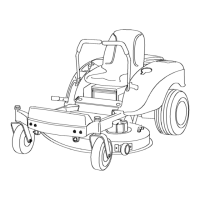

WARNING

Supportingthemachineonthelowermufer

shield(Figure26)maydamagetheshieldand

causethemachinetofall,injuringyouor

bystanders.

Donotusethelowermufershieldtosupport

themachine.

g299647

Figure26

1.Lowermufershield

Lubrication

GreasingtheBearings

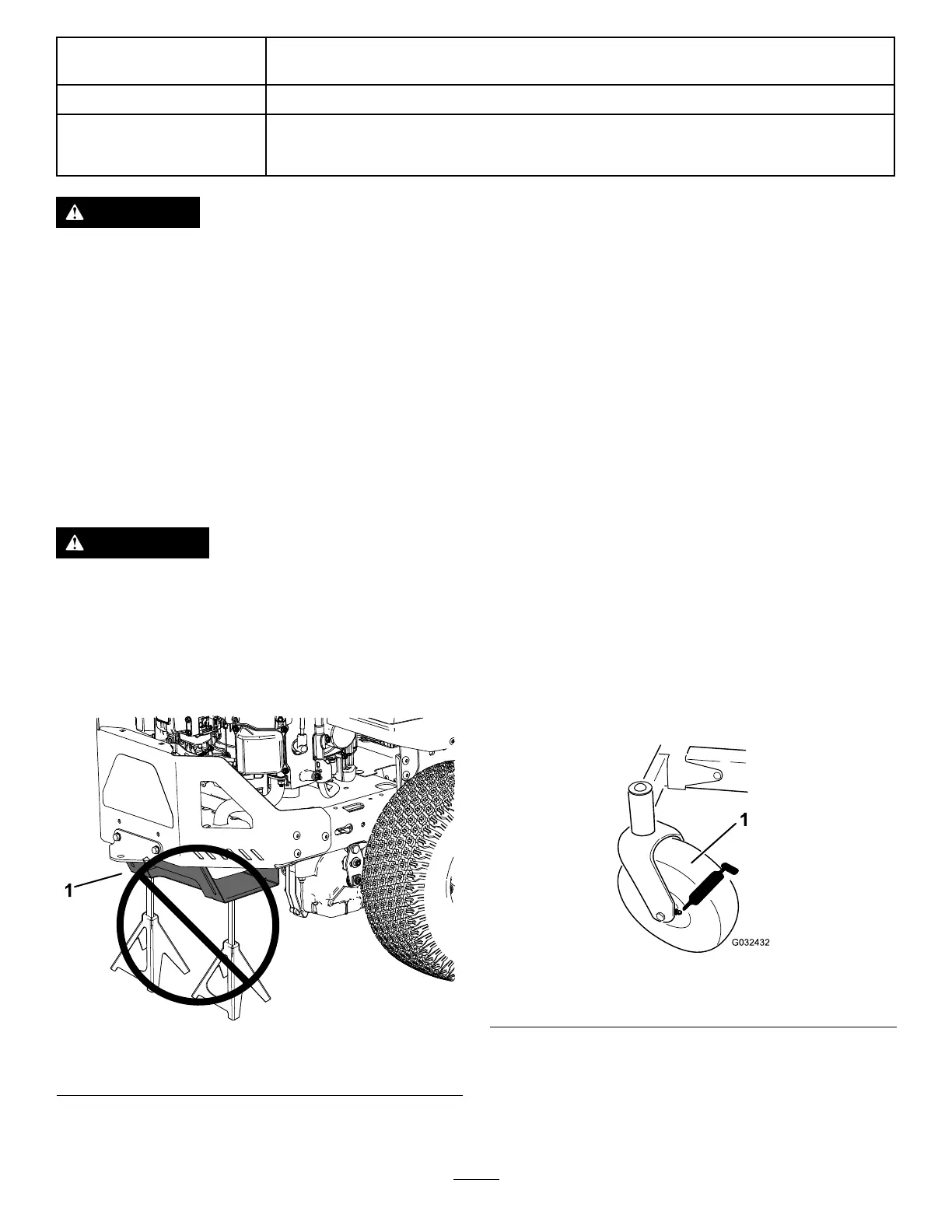

ServiceInterval:Every25hours—Greasethecaster

wheelbearings.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andmovethe

motion-controlleversoutwardtothePARK

position.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure27)witharag.

Note:Scrapeanypaintoffthefrontofthe

tting(s).

g032432

Figure27

1.Frontcastertire

4.Connectagreaseguntoeachtting(Figure27).

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

25

Loading...

Loading...