Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

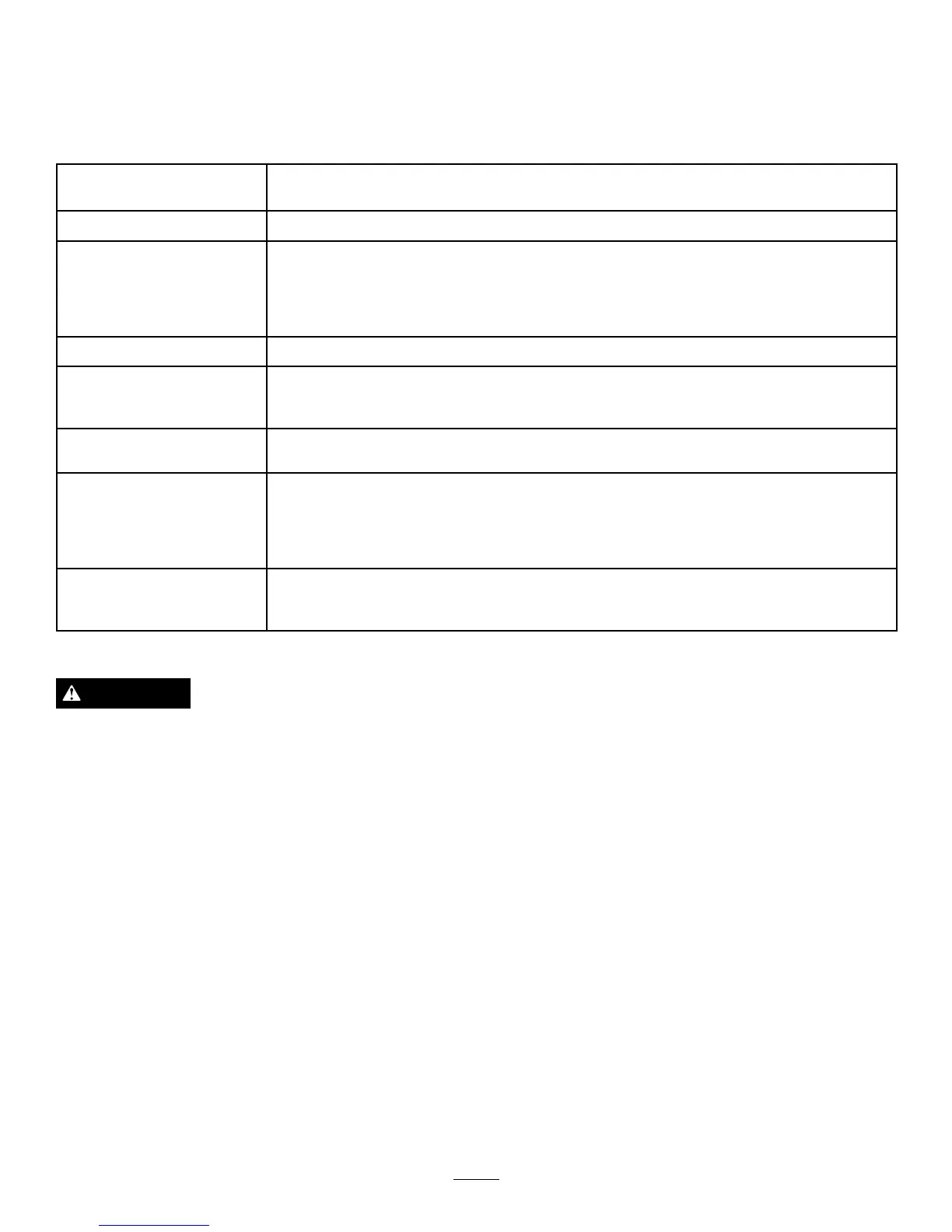

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst5hours

•Changetheengineoil.

Beforeeachuseordaily

•Checkthesafetyinterlocksystem.

•Cleanandchecktheaircleanerfoamelement.

•Cleantheengineairintakescreen.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage

Aftereachuse

•Cleanthemowerhousing.

Every25hours

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthebeltsforwear/cracks.

Every50hours

•Replacetheaircleanerpaperelement.

•Checkthesparkplug.

Every100hours

•Changetheengineoil.

•Changetheoillter.

•Replacethesparkplug.

•Replacethein-linefuellter

•Cleantheenginecoolingnsandshrouds.

Beforestorage

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Premaintenance

Procedures

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthepark

position.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seatadjustmentbolts

•Fuellter

•Batteryandbatterycables

Lubrication

GreasingtheBearings

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2GeneralPurposeLithiumBaseGrease

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

23

Loading...

Loading...