resultinirreparabledamagetothetransaxledrive

system.

RemovingHydraulicSystemFilters

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removethekeyandengage

theparkingbrake.

2.Locatethelterandguardsoneachtransaxledrive

system(Figure49).Removethreescrewssecuring

thelterguardandguard.

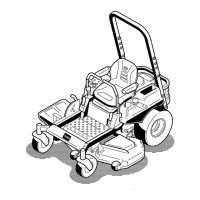

Figure49

Rightsideshown

1.Transaxledrive

4.Screws

2.Oillter

5.Ventplug

3.Filterguard

3.Carefullycleanareaaroundlters.Itisimportant

thatnodirtorcontaminationenterhydraulicsystem.

4.Locateandremovetheventplugoneach

transmission

5.Placeacontainerbelowtheltertocatchtheoilthat

drainswhenthelterisremoved.Unscrewthelter

toremoveandallowoiltodrainfromdrivesystem.

Repeatthisprocedureforbothlters.

InstallingtheHydraulicSystemFilters

ServiceInterval:Aftertherst50hours

Every400hours

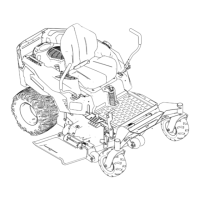

Figure50

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontacts

thelteradapterthentightenthelteranadditional

3/4to1fullturn.Repeatfortheotherlter

3.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

4.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofventplugholes.Stop

andinstalltheventplugs.Torqueplugsto180in-lb

(20.3N-m).

5.ContinuetoaddoiluntilitreachestheFULLCOLD

lineontheexpansionreservoir.Proceedtothe

BleedingtheHydraulicSystemsection.

Important:Failuretoperformthe

Bleeding

the Hy draulic System

procedureafterchanging

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

39

Loading...

Loading...