HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

Hydraulic-Fluid

Specications

HydraulicTankCapacity:45.4L(12USgallons)

Useonly1ofthefollowinguidsinthehydraulic

system:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedT oroDealerfor

moreinformation)

•ToroPremiumAllSeasonHydraulicFluid

(refertoyourAuthorizedToroDealerformore

information)

•IfeitheroftheaboveT orouidsarenotavailable,

youmayuseanotherUniversalTractor

HydraulicFluid(UTHF),buttheymustbeonly

conventional,petroleum-basedproducts.The

specicationsmustfallwithinthelistedrangefor

allthefollowingmaterialpropertiesandtheuid

shouldmeetthelistedindustrystandards.Check

withyourhydraulicuidsuppliertodetermineifthe

uidmeetsthesespecications.

Note:T orodoesnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswho

willstandbehindtheirrecommendations.

MaterialProperties

cStat40°C:55to62 Viscosity,ASTMD445

cStat100°C:9.1to9.8

Viscosityindex,ASTMD2270

140to152

PourPoint,ASTMD97-37to-43°C(-35to-46°F)

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemuidisavailablein20ml

(2/3oz)bottles.Onebottleissufcientfor15to

22L(4to6USgallons)ofhydraulicuid.Order

PartNo.44-2500fromyourAuthorizedService

Dealer.

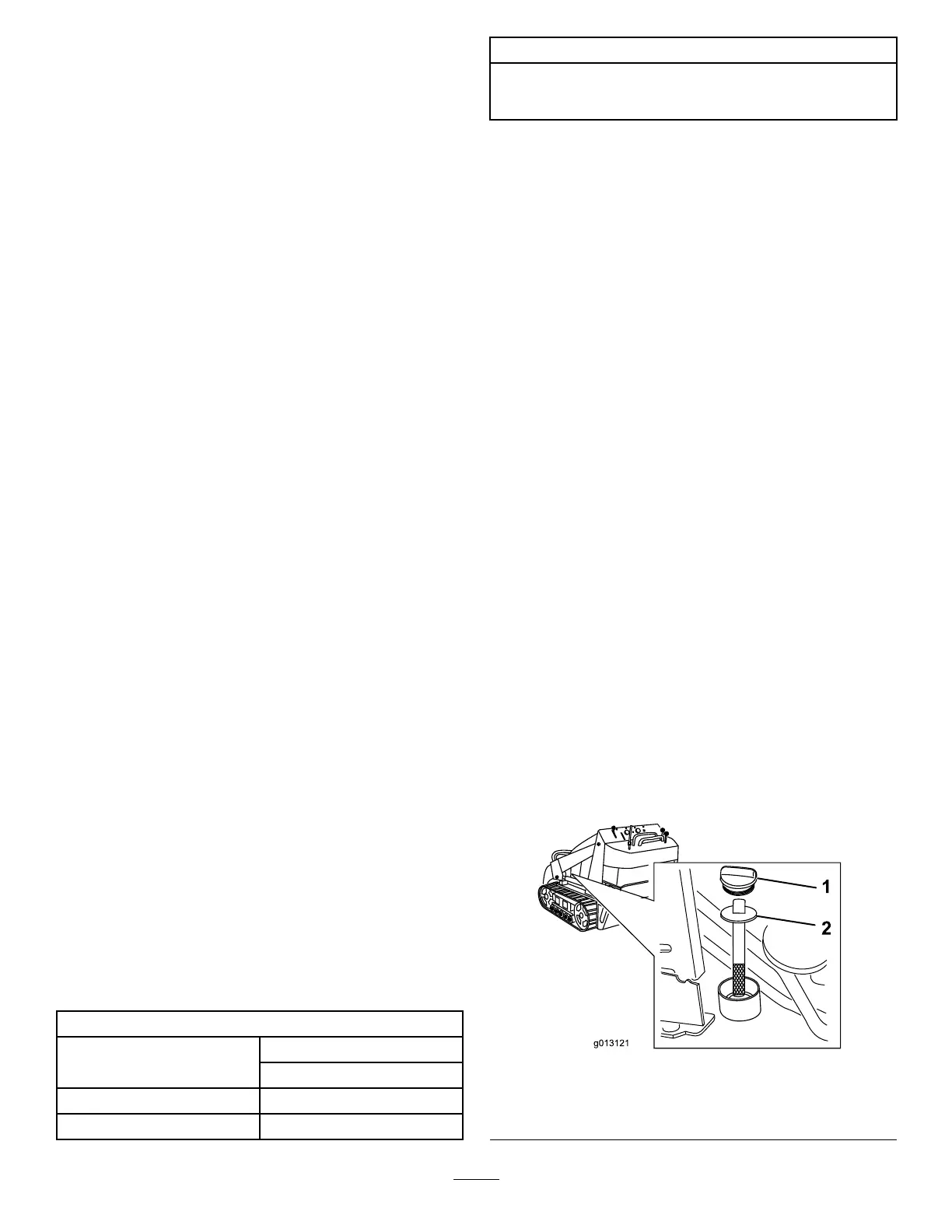

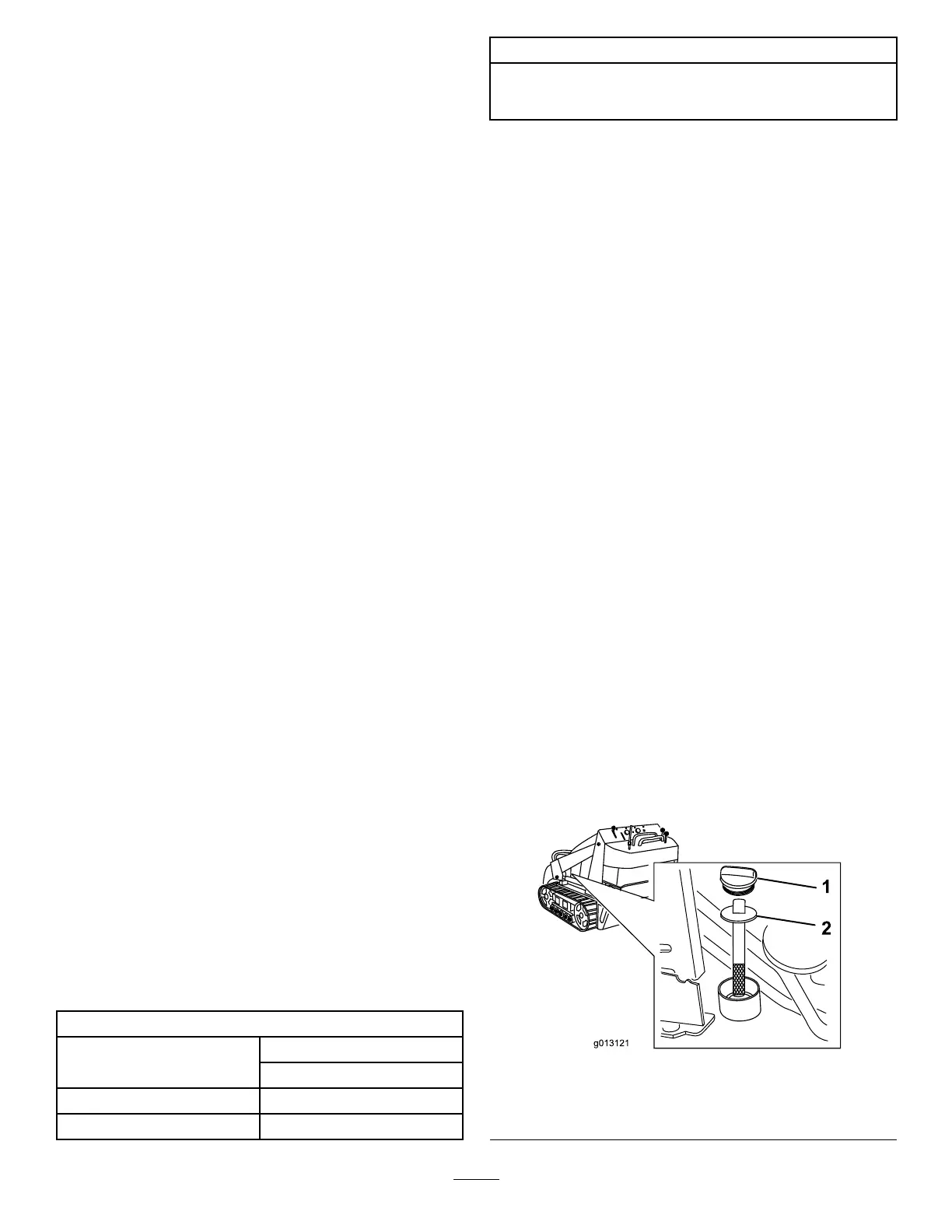

Checkingthe

Hydraulic-FluidLevel

ServiceInterval:Every25hours

Checkthehydraulic-uidlevelbeforetheengineis

rststartedandafterevery25operatinghours.

RefertoHydraulic-FluidSpecications(page42)for

hydraulic-uidspecications.

Important:Alwaysusethecorrecthydraulic

uid.Unspecieduidswilldamagethehydraulic

system.

1.Removeanyattachments.

2.Parkthemachineonalevelsurface,lowerthe

loaderarms,andfullyretractthetiltcylinder.

3.Shutofftheengine,removethekey,andallow

theenginetocool.

4.Openthehoodandremovetheleftsidescreen.

5.Cleantheareaaroundthellerneckofthe

hydraulictank(Figure60).

6.Removetheller-neckcapandchecktheuid

levelonthedipstick(Figure60).

Theuidlevelshouldbebetweenthemarkson

thedipstick.

g013121

Figure60

1.Filler-neckcap2.Dipstick

42

Loading...

Loading...