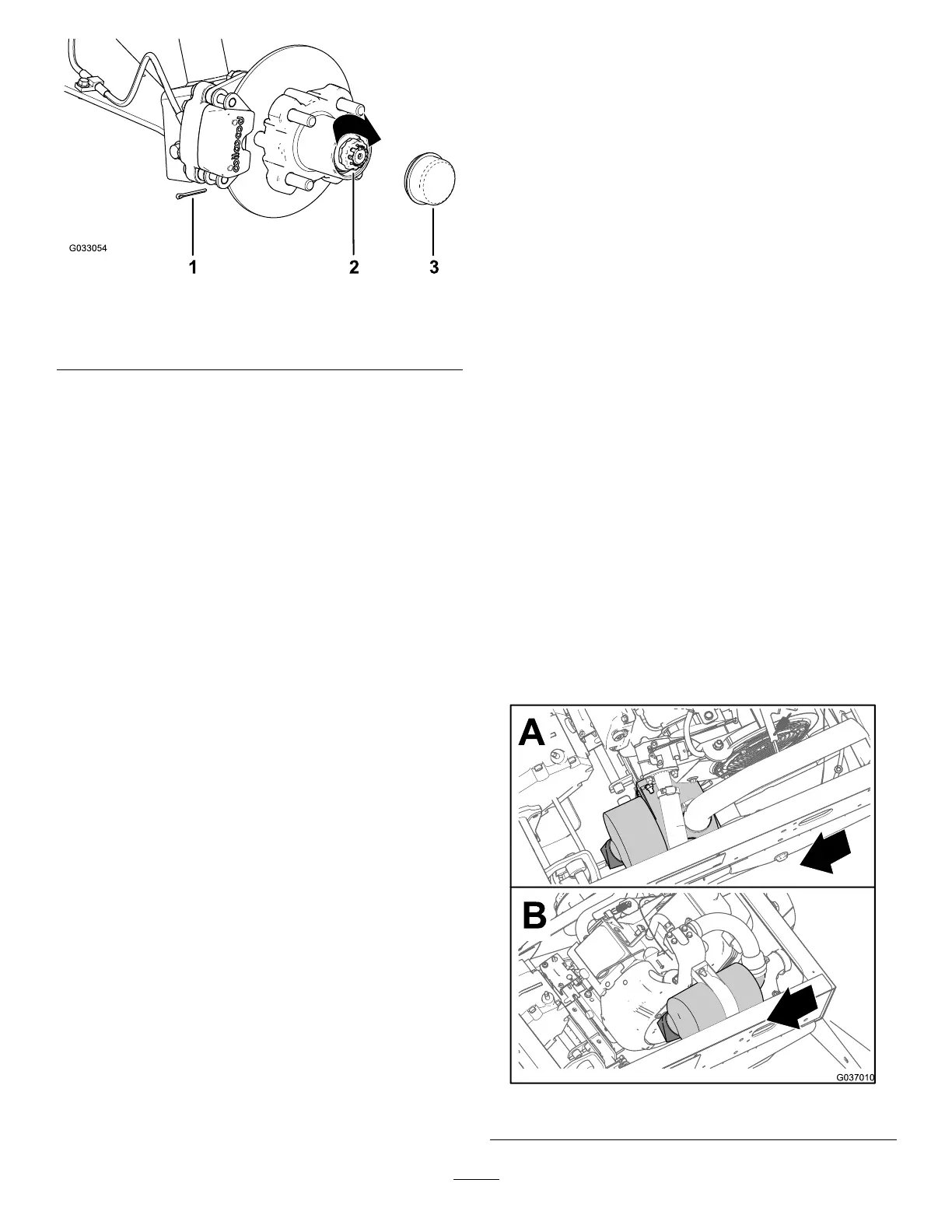

g033054

Figure 28

1. Cotter pin

3. Dust cap

2. Nut retainer

9. Install the cotter pin and bend each legs around

the retainer ( Figure 28 ).

10. Install the dust cap onto the hub ( Figure 28 ).

1 1. Repeat steps 1 through 10 for the hub and rotor

at the other side of the machine.

Installing the Brakes and Wheels

1. Clean the 2 ange-head bolts (3/8 x 3/4 inch) and

apply a coat of medium-strength thread-locking

compound to the threads of the bolts.

2. Align the brake pads to either side of the rotor

( Figure 23 ) and the holes in the caliper bracket

with the holes in the brake mount of the spindle

frame ( Figure 27 ).

3. Secure the caliper bracket to the spindle frame

( Figure 23 ) using the 2 ange-head bolts (3/8

x 3/4 inch).

T orque the 2 ange-head bolts to 47 to 54 N∙m

(35 to 40 ft-lb).

4. Align the holes in the wheel to the studs of the

hub and assemble the wheel to the hub with the

valve stem outward ( Figure 22 ).

Note: Ensure that the mounting surface of the

wheel is ush with the hub.

5. Secure the wheel to the hub using the lug nuts

( Figure 22 ).

T orque the lug nuts to 108 to 122 N∙m (80 to 90

ft-lb).

6. Repeat steps 1 through 5 for the brake and

wheel on the other side of the machine.

Engine Maintenance

Engine Safety

• Shut of f the engine, remove the key , and wait for

all moving parts to stop before checking the oil or

adding oil to the crankcase.

• Keep your hands, feet, face, clothing, and other

body parts away from the muf er and other hot

surfaces.

Servicing the Air Filter

Service Interval : Every 100 hours Replace the

air-lter element sooner if it dirty or

damaged.

Note: Service the air lter more frequently (every few

hours) if operating conditions are extremely dusty or

sandy .

Checking the Air Filter

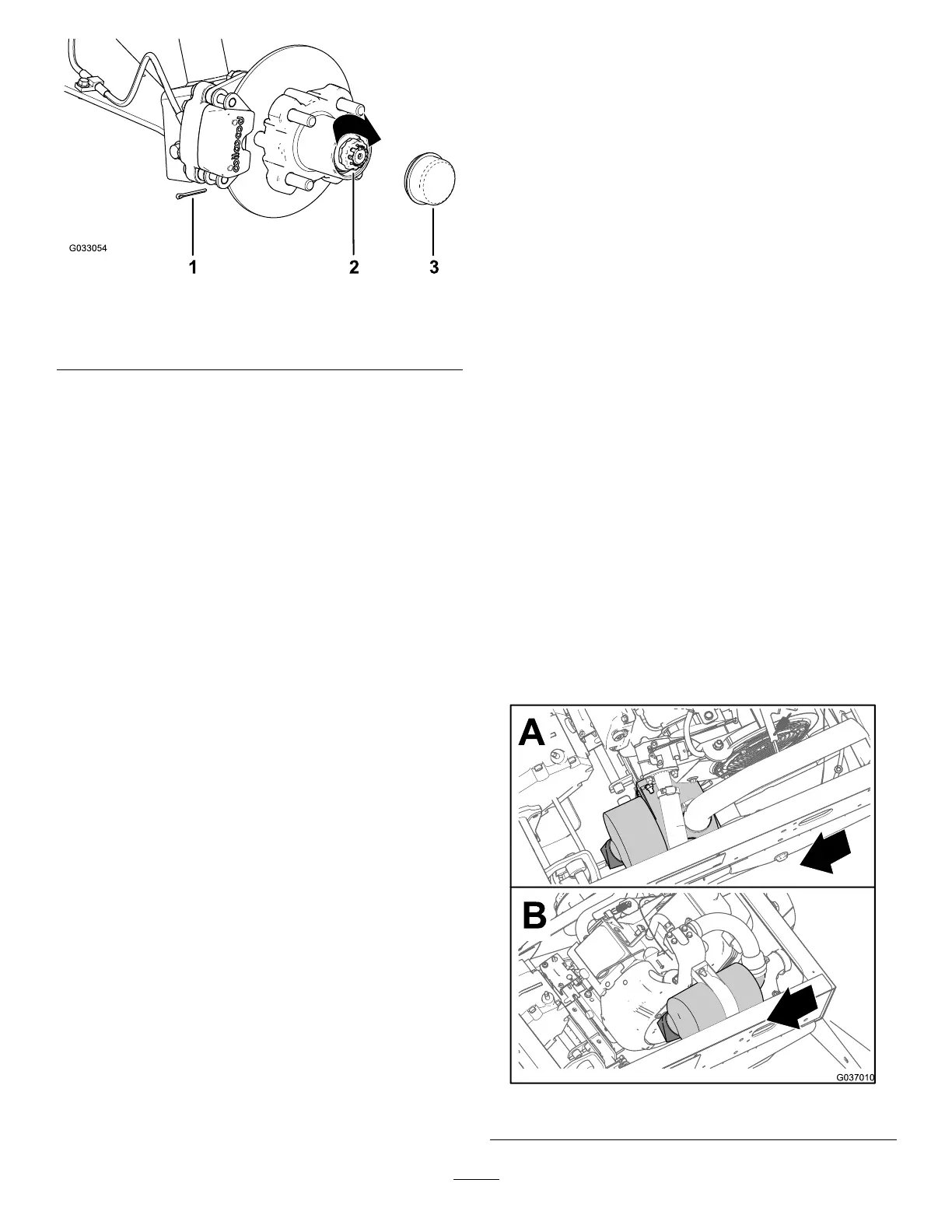

1. Raise the cargo bed and secure it with the prop

rod.

2. Check the air-cleaner body for damage which

could possibly cause an air leak ( Figure 29 and

Figure 30 ).

Note: Ensure the cover seals around the

air-lter body .

Note: Replace a damaged air-lter cover or

housing.

g037010

Figure 29

33

Loading...

Loading...