START INJECTION CONTROL

EFI - Functions of Engine EC

U

During engine starting, it is difficult for the

manifold pressure sensor (for D-type EFI) or the

air flow meter (for L-type EFI) to accurately

sense the manifold pressure or the amount of air

being taken in, due to large fluctuations in

engine speed

. For this reason, the Engine ECU

selects from its memory a basic injection

duration that is suitable for the coolant

temperature and engine speed, regardless of in-

take manifold pressure or intake air volume

. It

then adds to this an intake air temperature correc-

tion (See page 72) and a voltage correction (See

page 79) to obtain the actual injection duration

.

When the weather is cold, the cold start

injection system operates in order to improve

startability (See page

63)

.

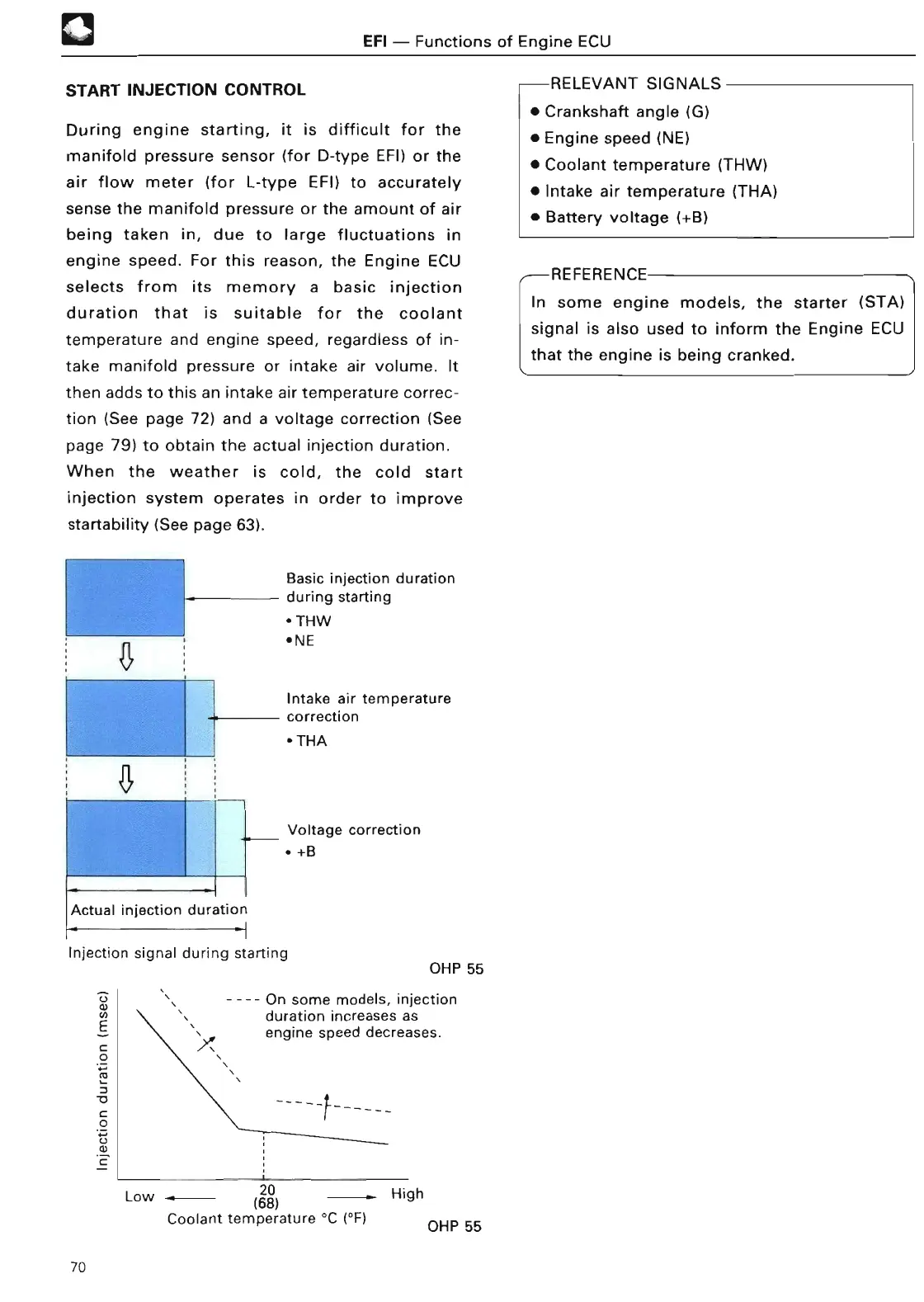

Basic injection duration

during sta

rt

in

g

• THW

OHP 5

5

Injection signal during sta

rt

in

g

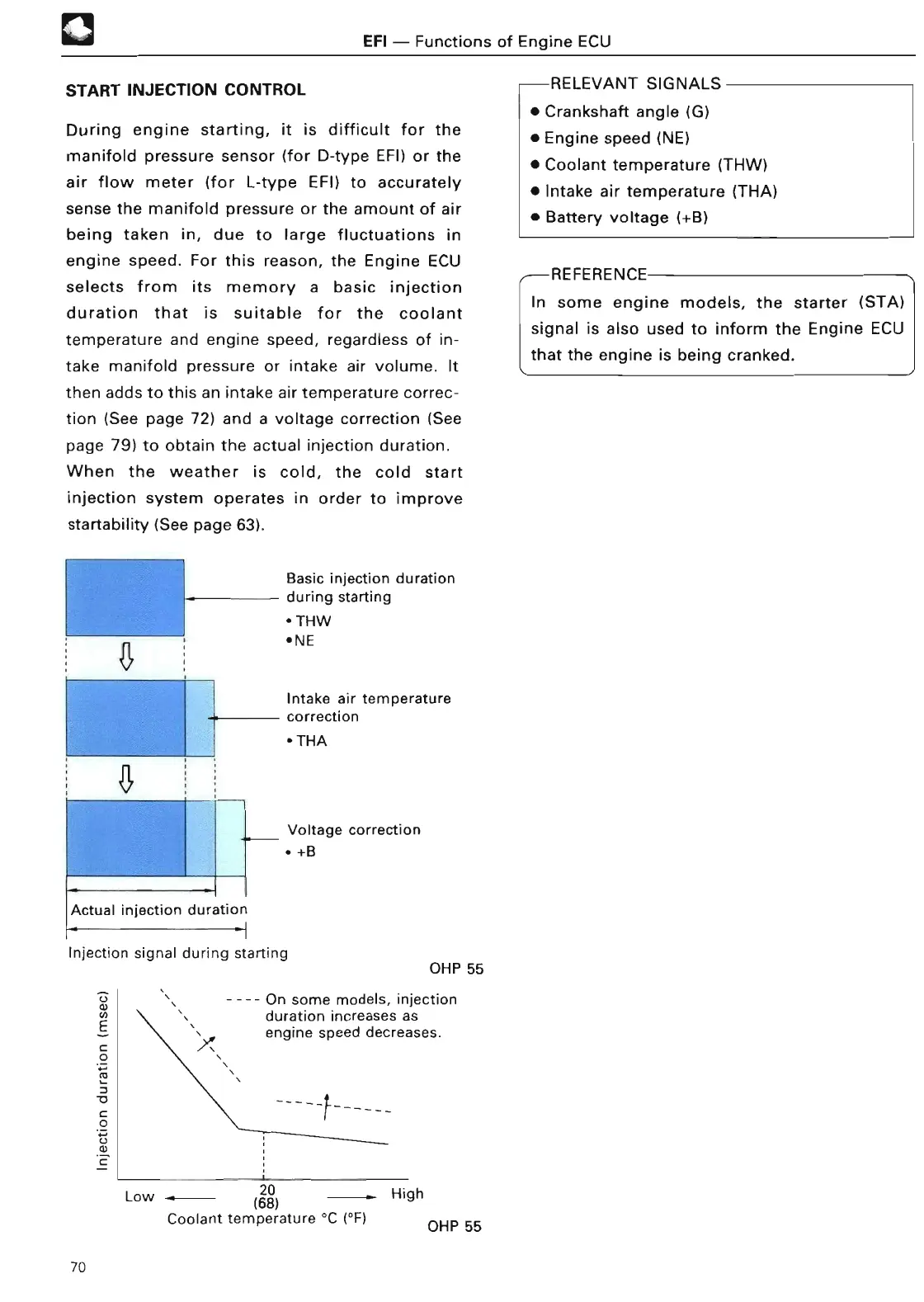

Low

---- On some models, injection

duration increases a

s

•N

E

Intake air temperature

correctio

n

•TH

A

Voltage correction

• +

B

20

(68

)

Coolant temperature °C (°F)

High

OHP 55

-RELEVANT SIGNALS

• Crankshaft angle (G)

• Engine speed (NE

)

• Coolant

temperature (THW)

• Intake air

temperature (THA)

• Battery voltage (+B

)

REFERENCE

In some engine models, the starter (STA)

signal is also used to inform the Engine ECU

that the engine is being cranked

.

70

Loading...

Loading...