42

CVHE-SVX005B-EN

NNOOTTIICCEE

PPrrooppeerr RReeffrriiggeerraanntt VVeenntt LLiinnee

TTeerrmmiinnaattiioonn!!

FFaaiilluurree ttoo pprrooppeerrllyy tteerrmmiinnaattee aa rreeffrriiggeerraanntt vveenntt

lliinnee ccoouulldd rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee..

IImmpprrooppeerrllyy tteerrmmiinnaattiinngg aa rreeffrriiggeerraanntt vveenntt lliinnee

ccoouulldd aallllooww rraaiinn ttoo eenntteerr tthhee lliinnee.. AAccccuummuullaatteedd

rraaiinnwwaatteerr ccoouulldd ccaauussee tthhee rreelliieeff ddeevviiccee ttoo

mmaallffuunnccttiioonn;; oorr,, iinn tthhee ccaassee ooff aa rruuppttuurree ddiisskk,, tthhee

rraaiinnwwaatteerr pprreessssuurree ccoouulldd ccaauussee tthhee ddiisskk ttoo rruuppttuurree,,

aalllloowwiinngg wwaatteerr ttoo eenntteerr tthhee cchhiilllleerr..

• Route the vent-line piping so that it discharges

outdoors in an area that will not spray refrigerant

on anyone. Position the vent-line discharge at least

15 ft (4.6 m) above grade level and at least 20 ft

(6.1 m) from any building opening. Provide a vent-

line termination that cannot be blocked by debris or

accumulate rainwater.

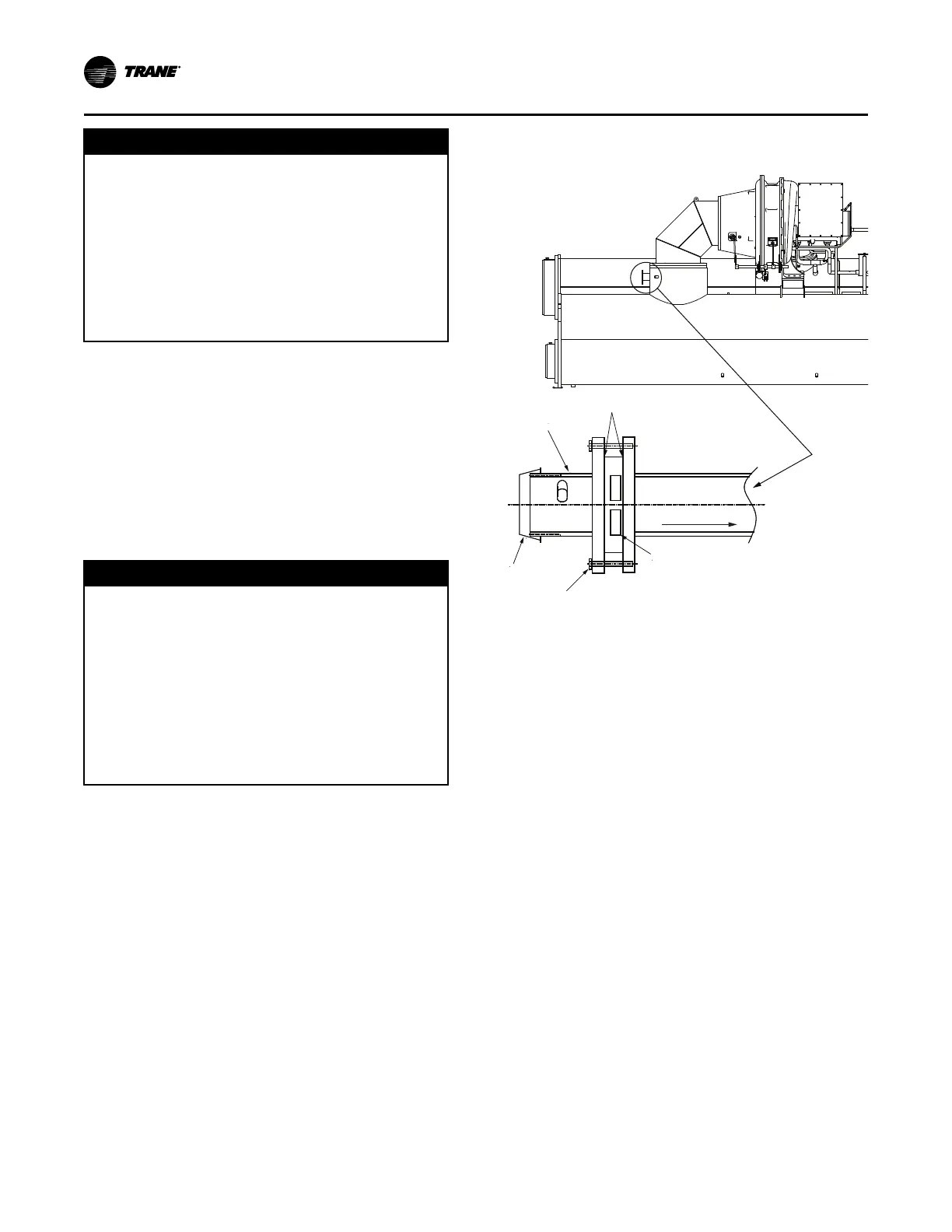

• Provide a drip leg on the vent line (refer to the

following figure [arrangement for rupture disk relief

piping]). Provide a standard 1/4-in. FL x 1/4-in. NPT,

capped refrigerant service valve to facilitate liquid

removal.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee..

AAllll vveenntt lliinneess mmuusstt bbee eeqquuiippppeedd wwiitthh aa ddrriipp lleegg ooff

ssuuffffiicciieenntt vvoolluummee ttoo hhoolldd tthhee eexxppeecctteedd

aaccccuummuullaattiioonn ooff wwaatteerr aanndd//oorr rreeffrriiggeerraanntt.. TThhee ddrriipp

lleegg mmuusstt bbee ddrraaiinneedd ppeerriiooddiiccaallllyy ttoo aassssuurree tthhaatt iitt

ddooeess nnoott oovveerrffllooww aanndd aallllooww fflluuiidd ttoo ffllooww iinnttoo tthhee

hhoorriizzoonnttaall ppoorrttiioonn ooff tthhee vveenntt lliinnee.. TTrraannee aassssuummeess

nnoo rreessppoonnssiibbiilliittyy ffoorr eeqquuiippmmeenntt ddaammaaggee ccaauusseedd bbyy

iinnssuuffffiicciieenntt ddrraaiinnaaggee ooff ddrriipp lleegg..

• Consult local regulations and codes for any

additional relief line requirements and refer to

appropriate refrigerant handling guidelines. For

chillers with R-123 refrigerant, refer to Installation,

Operation, and Maintenance: R-123 Low-Pressure

Refrigerant Handling Guidelines Conservation and

Safe Handling of R-123 Refrigerant in Trane Chillers

for Service Technicians (CTV-SVX05*-EN). For

chillers with R-514A refrigerant, refer to Installation,

Operation, and Maintenance: R-514A Low-Pressure

Refrigerant Handling Guidelines Conservation and

Safe Handling of R-514A Refrigerant in Trane

Chillers for Service Technicians (CTV-SVX008*-EN).

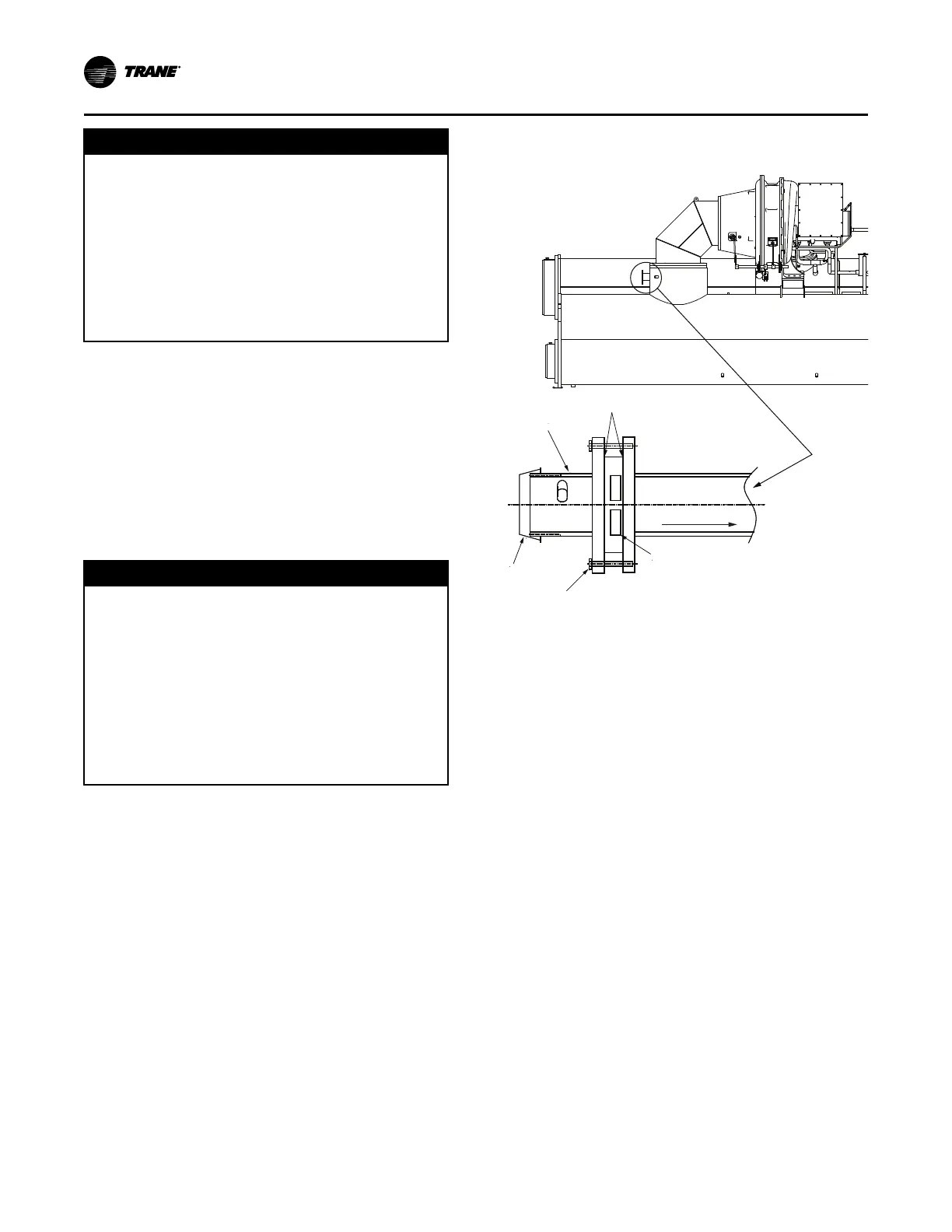

Figure 24. Rupture disk location and cross section of

rupture disk

Outside pipe

assembly

Gasket

Cap

Bolt

Rupture disk

Suction connection

NNoottee:: Pipe connection is 3 in. (76.2 mm) NPT, except

250E evaporator/250L condenser units with heat

recovery which have a 4 in. (101.6 mm) NPT pipe

connection.

VVeenntt PPiippiinngg

Loading...

Loading...