90

CVHE-SVX005B-EN

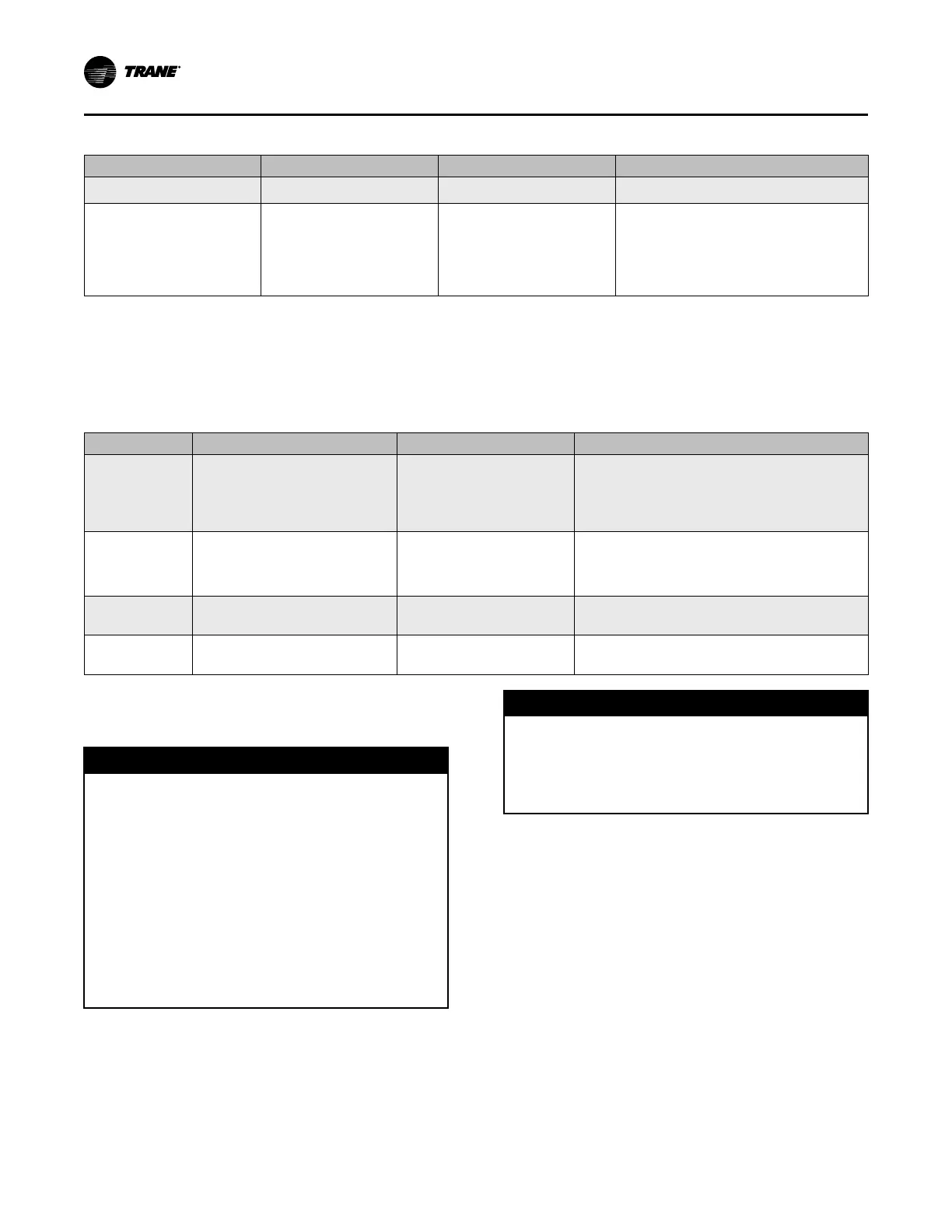

Table 21. Recommended maintenance (continued)

Daily Every 3 months Every 6 months Annually

(a)

,

(b)

Submit a sample of the compressor oil to a Trane-

qualified laboratory for comprehensive analysis.

Measure the compressor motor winding

resistance to ground; a qualified service

technician should conduct this check to ensure

that the findings are properly interpreted. Contact

a qualified service organization to leak-test the

chiller; this procedure is especially important if

the system requires frequent purging.

(a)

Every three years, use a non-destructive tube test to inspect the condenser and evaporator tubes. It may be desirable to perform tube tests on these

components at more frequent intervals depending upon chiller application. This is especially true of critical process equipment. Ask your Sales account

manager for a copy of engineering bulletin (CTV-PRB024*-EN) for clarification of the role of eddy current testing in chiller maintenance by providing

information about eddy current technology and heat exchanger tubing.

(b)

Contact a qualified service organization to determine when to conduct a complete examination of the unit to discern the condition of the compressor and

internal components. Check the following: chronic air leaks (which can cause acidic conditions in the compressor oil and result in premature bearing wear)

and evaporator or condenser water tube leaks (water mixed with the compressor oil can result in bearing pitting, corrosion, or excessive wear).

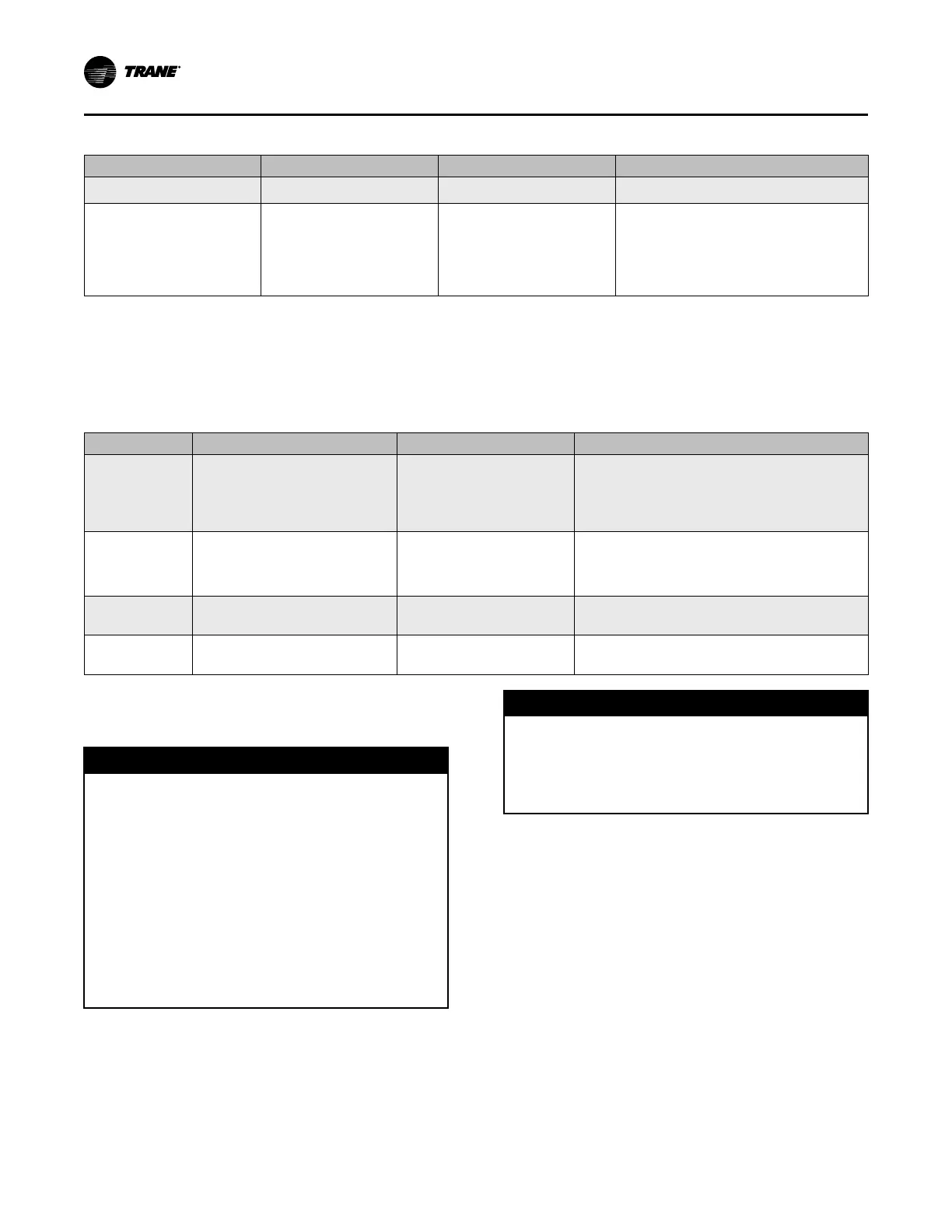

Table 22. Recommended maintenance of optional features

Feature

Every 3 months Every 6 months Annually

Waterbox Coatings

Inspect waterbox coatings within the

first 1–3 months to determine a

required maintenance schedule for your

job site. Refer to “Waterbox and

Tubesheet Protective Coatings,” p. 94

for more information.

Waterbox Anodes

Inspect waterbox anodes within the first

1–3 months to determine a required

maintenance schedule for your job site.

Refer to “Sacrificial Anodes,” p. 94 for

more information.

Gantries

Lubricate the gantries annually. Use ConocoPhillips

MegaPlex® XD3 (gray in color), LPS® MultiPlex Multi-

Purpose (blue in color), or equivalent.

Hinges

Lubricate the hinges annually. Use ConocoPhillips

MegaPlex® XD3 (gray in color), LPS® MultiPlex Multi-

Purpose (blue in color), or equivalent.

Recommended Compressor Oil

Change

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

MMiixxiinngg rreeffrriiggeerraannttss oorr ooiillss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee iinncclluuddiinngg bbeeaarriinngg ddaammaaggee,,

iinnttrroodduuccttiioonn ooff aacciiddss iinnttoo tthhee cchhiilllleerr,, oorr ccoonnttiinnuuoouuss

ppuurrggee ppuummpp--oouutt iinn hhiigghh--hheeaadd//hhiigghh aammbbiieenntt

aapppplliiccaattiioonnss..

CCeennTTrraaVVaacc™™ cchhiilllleerrss aarree mmaannuuffaaccttuurreedd wwiitthh

ddiiffffeerreenntt rreeffrriiggeerraanntt//ooiill ssyysstteemmss:: 11)) cchhiilllleerrss uussiinngg

RR--112233 rreeffrriiggeerraanntt aanndd OOIILL0000002222 ccoommpprreessssoorr ooiill,,

aanndd 22)) cchhiilllleerrss uussiinngg RR--551144AA rreeffrriiggeerraanntt aanndd

vvaarriioouuss TTrraannee PPOOEE--bbaasseedd ccoommpprreessssoorr ooiillss..

AAllwwaayyss vveerriiffyy pprrooppeerr rreeffrriiggeerraanntt aanndd ooiill ffoorr yyoouurr

cchhiilllleerr.. DDoo NNOOTT mmiixx rreeffrriiggeerraannttss aanndd ooiillss..

This Installation, Operation, and Maintenance manual

applies to CenTraVac™ chillers with two different

refrigerant and compressor oil systems:

• R-123 refrigerant and OIL00022 compressor oil.

• R-514A refrigerant and Trane OIL00379/OIL00380

compressor oil.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee..

FFoollllooww ooiill uussee iinnssttrruuccttiioonnss ffoorr ppoosstt--sseerrvviiccee

ccoommpprreessssoorr aaiirr--rruunn pprroocceedduurreess..

For post-service compressor air-run procedures on

CenTraVac™ chillers that use R-514A refrigerant and

POE oil:

1. Use Trane OIL00381/OIL00382 compressor oil for

the air-run procedure.

2. Upon completion of the air-run procedure, drain the

OIL00381/OIL00382 from the sump.

3. After unit final assembly and evacuation, refill the

sump with Trane OIL00379/OIL00380.

IImmppoorrttaanntt:: Verify proper refrigerant and compressor

oil for your chiller before proceeding!

After the first six months of accumulated operation or

after 1000 hours operation—whichever comes first—it

is recommended to change the oil and filter. After this

oil change, it is recommended to subscribe to the Trane

annual oil analysis program rather than automatically

change the oil as part of scheduled maintenance.

RReeccoommmmeennddeedd MMaaiinntteennaannccee

Loading...

Loading...