About Trane and American Standard Heating and

Air Conditioning

Trane and American Standard create comfortable, energy

efficient indoor environments for residential applications.

For more information, please visit www.trane.com or

www.americanstandardair.com

The AHRI Certified mark indicates company participation in the

AHRI Certification program. For verification of individual certified

products, go to ahridirectory.org.

The manufacturer has a policy of continuous data improvement and it

reserves the right to change design and specifications without notice. We

are committed to using environmentally conscious print practices.

© 2020

18-BG04D1-12A-EN 29 May 2020

Supersedes 18-BG04D1-12-EN (June 2019)

Table 7. IGN LED Diagnostic Indicators

Status LEDs

IGN Board Diagnostic Codes

There are two LEDs on the IGN board that provide status and

diagnostic information. Refer to Table 7 for a description of the

LED codes.

SteadyOFF CheckPowerorFailedBoard 2Flashes

SystemLockout:Failedtodetector

sustain flame

SlowFlashRate Normal,NoCallforHeat 3Flashes

Pressureswitchproblemdetected

FastFlashRate Notused 4Flashes

HighLimitswitchprotectiondevice

open

SteadyON Normal,NoCallforHeat 5Flashes

Flamesensedandgasvalvenot

energizedorflamesensedandno"W"

signal

6Flashes

FlameRolloutSwitchopen

7Flashes

Thermostatmiswired;W1&W2

Fast Flash Rate:TheLEDwillflashonfor1/4second,andofffor1/4second

Slow Flash Rate:TheLEDwillflashonfor3/4second,thenofffor1/4second.

Thepausebetweengroupsoffastflashesis3seconds.

Status LED Liteport LED

IGN Diagnostic Indicators Flash Codes

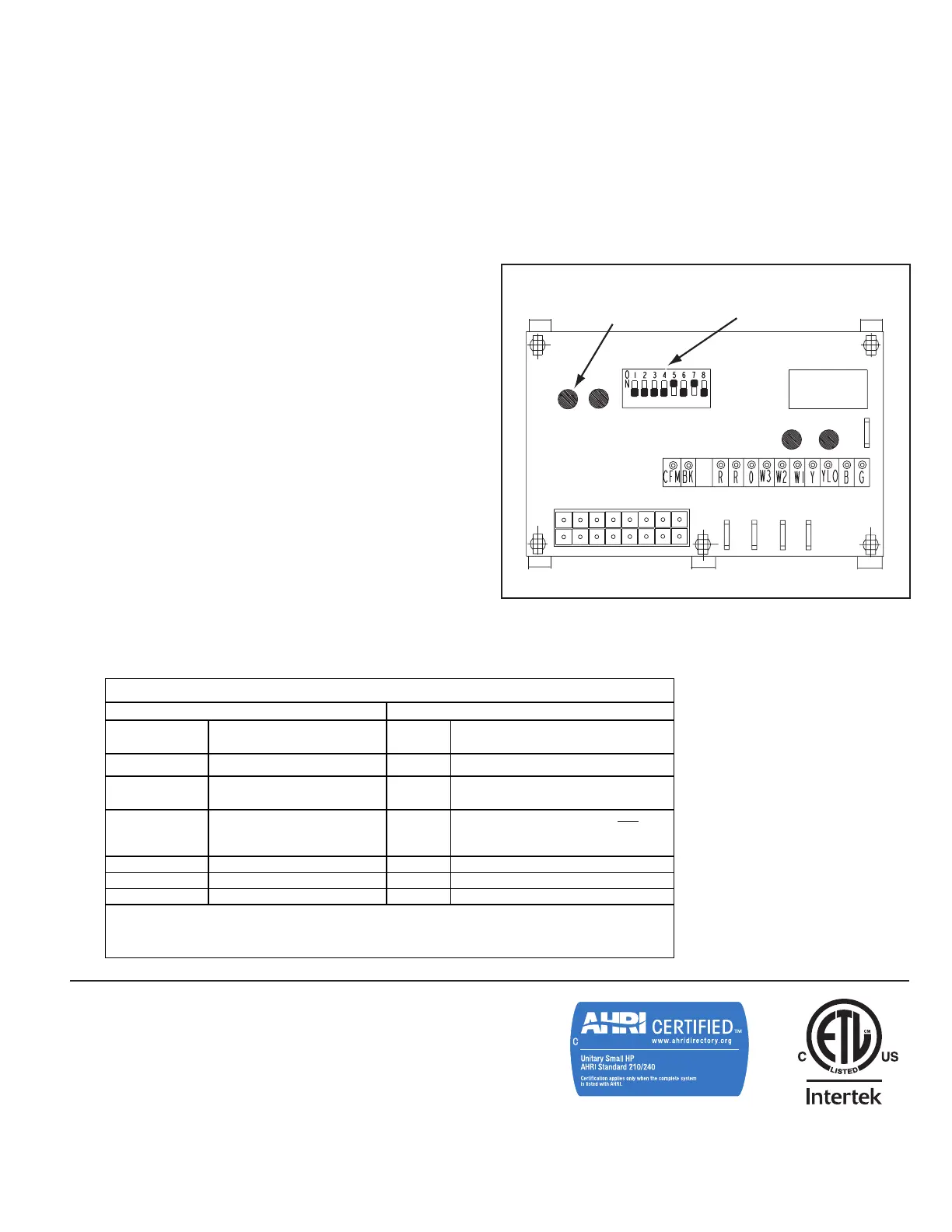

Figure 23. ECM Fan Control

ECM Fan Motor Adjustments

If the airflow needs to be increased or decreased, see the

Airflow Table in the SERVICE FACTS. Information on chang-

ing the speed of the blower motor is in the Blower Performance

Table. Blower speed changes are made on the ECM Fan Control

mounted in the control box. The ECM Fan Control controls the

variable speed motor. There is a bank of 8 dip switches, (See

Figure 23 below), located on the board. The dip switches work in

pairs to match the cooling/heat airflow (CFM/TON), Fan off-delay

options and electric heat airflow adjustment. The switches appear

as shown in the Figure below.

6. Remove the manifold retaining screws and pull the burner-

manifold assembly from the heat exchanger.

7. Remove the inlet turbulators being careful not to break or dam-

age them.

8. Wipe the flue box and flue baffles clean with a clean, dry cloth.

9. Never use combustible cleaning fluids on any part of the furnace.

10. Replace all gaskets with new ones.

11. Replace all damaged or broken turbulators with new ones.

12. Reassemble the unit by reversing Steps 2 through 7 above.

Take care that all gaskets seat properly.

13. Check all wires for correct installation by referring to the unit’s

electrical wiring diagram in the SERVICE FACTS.

14. Leak test all gas line connections with a soap and water solution

or the equivalent.

15. Re-install the CONTROL/HEAT access panels and the flue

hood.

16. Visually inspect the unit to ensure that the airflow opening for

combustion is not obstructed.

17. Follow the start-up procedure on page 21 to place the unit back

in service.

CFM

SELECTION

LIGHT

DIP

SWITCHES

CFM FAN

RW3 W2 W1

Y

Y LO

J

21C800796P01

CNT03600

Loading...

Loading...