18-AC128D1-1B-EN 13

LIFT

STEP 1 - Use the refrigerant line total length

and lift measurements from Section 5.3.

Total Line Length = __________ Ft.

Vertical Change (Lift) = __________ Ft.

14.2 Subcooling Charging in Cooling (Above 55º F Outdoor Temp.)

Design Subcooling Value = __________º F

(from nameplate or Service Facts)

Final Subcooling Target = __________º F

Subcooling Correction = __________º F

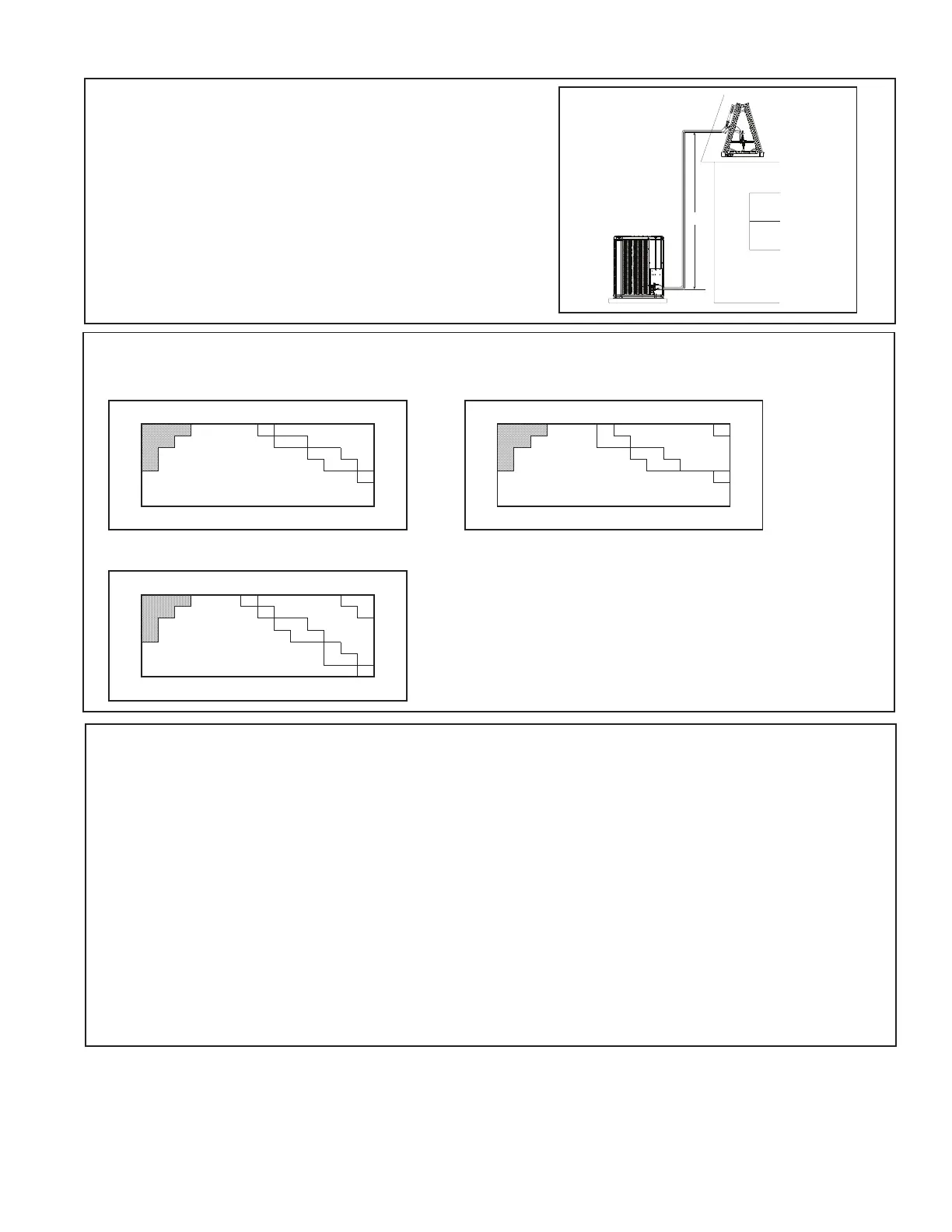

STEP 2 -

Determine the final subcooling target using total Line Length and Lift measured in STEP 1 and the charts below.

018 & 030 Models

50

1°

40

30

25

Use Design Subcooling

15

1°

10

0

20 30 40 50 60 70 80 90 100 110 120 130 140 150

Add 1°

REFRIGERANT LINE LIFT (FT)

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

TOTAL REFRIGERANT LINE LENGTH (FT) - [ includes lift ]

Add 2°

Add 1°

048 & 060 Models

50

1°

40

1°

30

25

Use Design Subcooling

15

10

0

1°

20 30 40 50 60 70 80 90 100 110 120 130 140 150

Add 4°

Add 2°

Add 1°

Add 1°

REFRIGERANT LINE LIFT (FT)

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

TOTAL REFRIGERANT LINE LENGTH (FT) - [ includes lift ]

024, 036 & 042 Models

50

4°

40

30

25

Use Design Subcooling

15

1°

10

0

20 30 40 50 60 70 80 90 100 110 120 130 140 150

Add 1°

Add 2°

REFRIGERANT LINE LIFT (FT)

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

TOTAL REFRIGERANT LINE LENGTH (FT) - [ includes lift ]

Add 1°

STEP 3 - Stabilize the system by operating for a minimum of 20 minutes whenever charge is removed or added

before accurate measurements can be made.

STEP 4 - Measure the liquid line temperature and pressure at the outdoor unit’s service valve.

Measured Liquid Line Temp = __________ º F

Liquid Gage Pressure = __________ PSI

Final Subcooling Target = __________ º F

STEP 5 - Use the final subcooling target, refrigerant temperature and pressure from STEP 4, to determine the

proper liquid gage pressure using Table 14.2.

Example: Assume a 12º F Final Subcooling Target and liquid temp of 90º F.

1. Locate 12º F Final Subcooling in Table 14.2.

2. Locate the Liquid Temperarature (90º F) in the left column.

3. The Liquid Gage Pressure should be approximately 327 PSI. (This is the shown as the intersection of the

Final Subcooling column and the Liquid Temperature row).

Loading...

Loading...