18-AC128D1-1B-EN 15

STEP 9 - Record System Information for

reference.

Record system pressures and temperatures

after charging is complete.

Outdoor model number = _________________

Measured Outdoor Ambient = __________ º F

Measured Indoor Ambient = __________ º F

Measured Liquid Line Temp = __________ º F

Measured Suction Line Temp = __________ º F

Liquid Gage Pressure = __________ PSI

Suction Gage Pressure = __________ PSI

STEP 10 - If repairs must be made after system is charged, properly and safely remove and isolate refrigerant and

purge the section of the system needing repair with oxygen free nitrogen prior to opening the circuit.

The refrigerant charge should be recovered into the correctly marked recovery cylinders. Ensure that the correct

number of cylinders for holding the total system charge is available. Only use cylinders designated for the recovered

refrigerant and labelled for that refrigerant. Cylinders shall be complete with pressure-relief valve and associated

shut-off valves in good working order.

Ensure that the outlet for the vacuum pump is not close to any potential ignition sources and that ventilation is

available.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery cylinder. Do not mix

refrigerants.

If compressors or compressor oils are to be removed, ensure that they have been evacuated to an acceptable level

to make certain that FLAMMABLE REFRIGERANT does not remain within the lubricant.

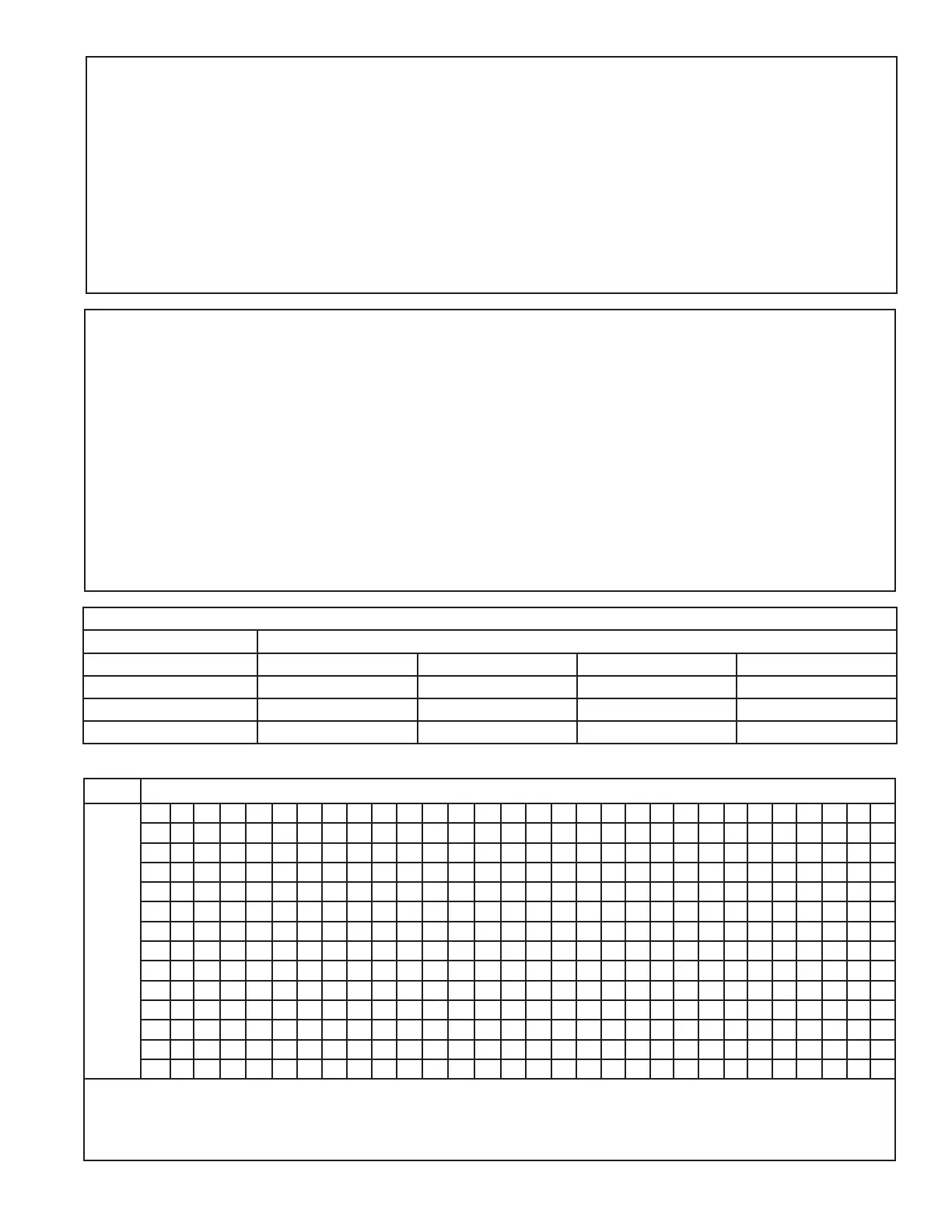

Indoor Wet Bulb Temp (F)

Outdoor

Dry

Bulb

Temp.

(F)

50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78

55 7 9 10 11 12 14 15 17 18 20 21 23 24 26 27 29 30

60 5 7 8 9 10 12 13 15 16 18 19 21 22 24 25 27 28 30 31

65 4 6 8 101113141617 18 19 2122242527282731

70 5 7 8 101113 14 16 1718192122242527283031

75 5 6 7 9 10 12 14 16 18 19 21 22 24 26 28 29 31 32

80 4 6 7 9 10 11 12 14 16 18 19 21 23 25 26 28 29 31 33

85 4 6 7 9 10 13 14 16 18 20 21 23 24 26 28 29 30 31 32

90 4 6 8 1011131416182022242527283031

95 4 6 8 1013141618202223 25 262829

100 6 8 10 12 13 16 18 20 21 23 25 27 29

105 4679111315182022242628

110 4 7 9 11 13 16 18 21 23 26 28

115 6 9 12 14 16 19 21 24 26

Using a digital psychrometer, measure the return air wet-bulb temperature at the unit just before the coil. Also measure the outdoor dry-bulb tem-

perature. Use these temperatures to locate the target superheat on the charging table. Do not attempt to charge the system if these conditions fall

outside of this charging table.

ADD refrigerant to DECREASE total superheat. REMOVE refrigerant to INCREASE total superheat. Always allow 10 to 15 minutes of operature

after any refrigerant or air flow change prior to determining the final superheat.

Fixed Orifice Superheat Charging Table

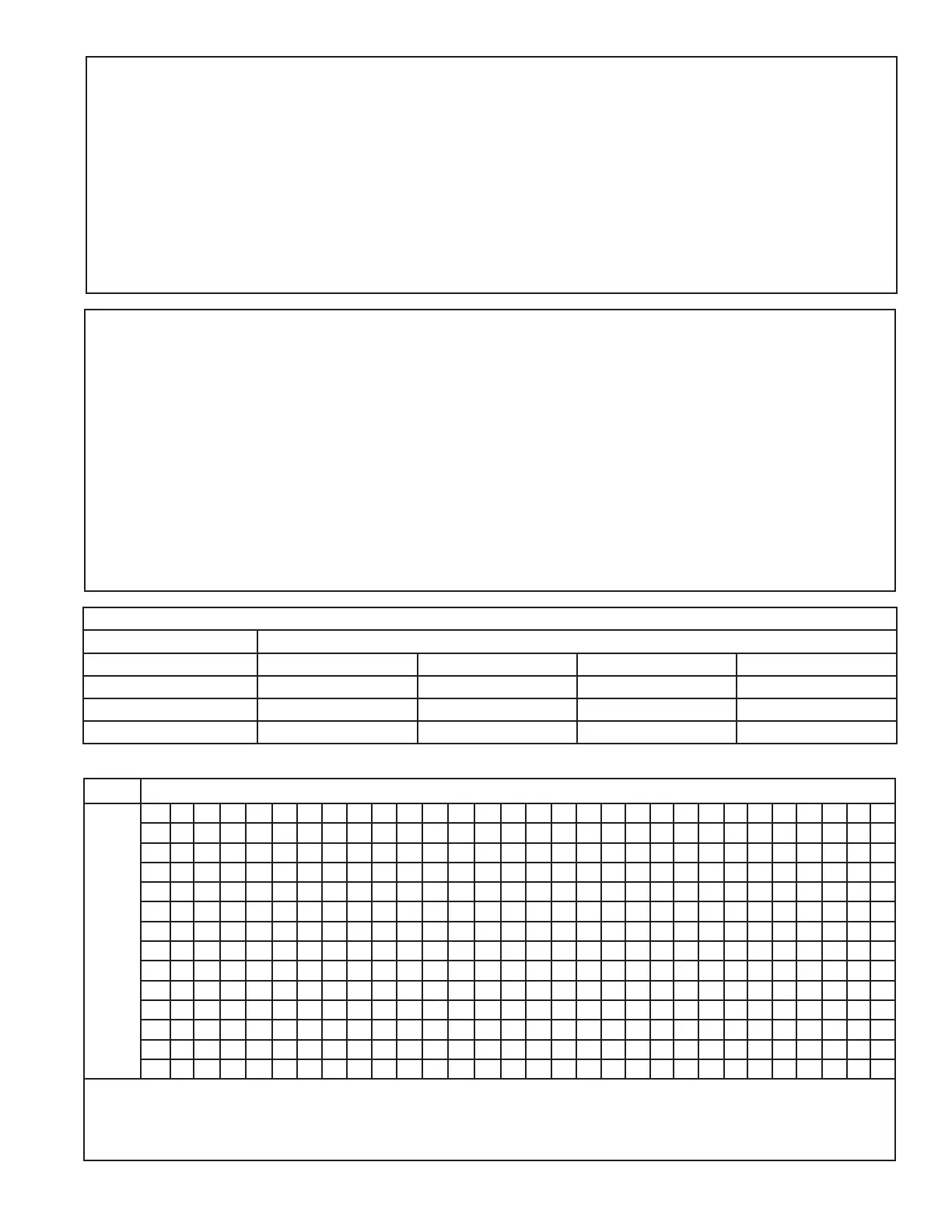

Nitrogen Purge Times

Flow Rate Lineset Length

CuFT/Hr < 50 feet < 100 feet < 150 feet < 200 feet

15 2 Minutes 4 Minutes 6 Minutes 8 Minutes

30 1 Minute 2 Minutes 3 Minutes 4 Minutes

60 1 Minute 1 Minute 2 Minutes 2 Minutes

Loading...

Loading...