8 18-BC117D1-1B-EN

3-4” from valv

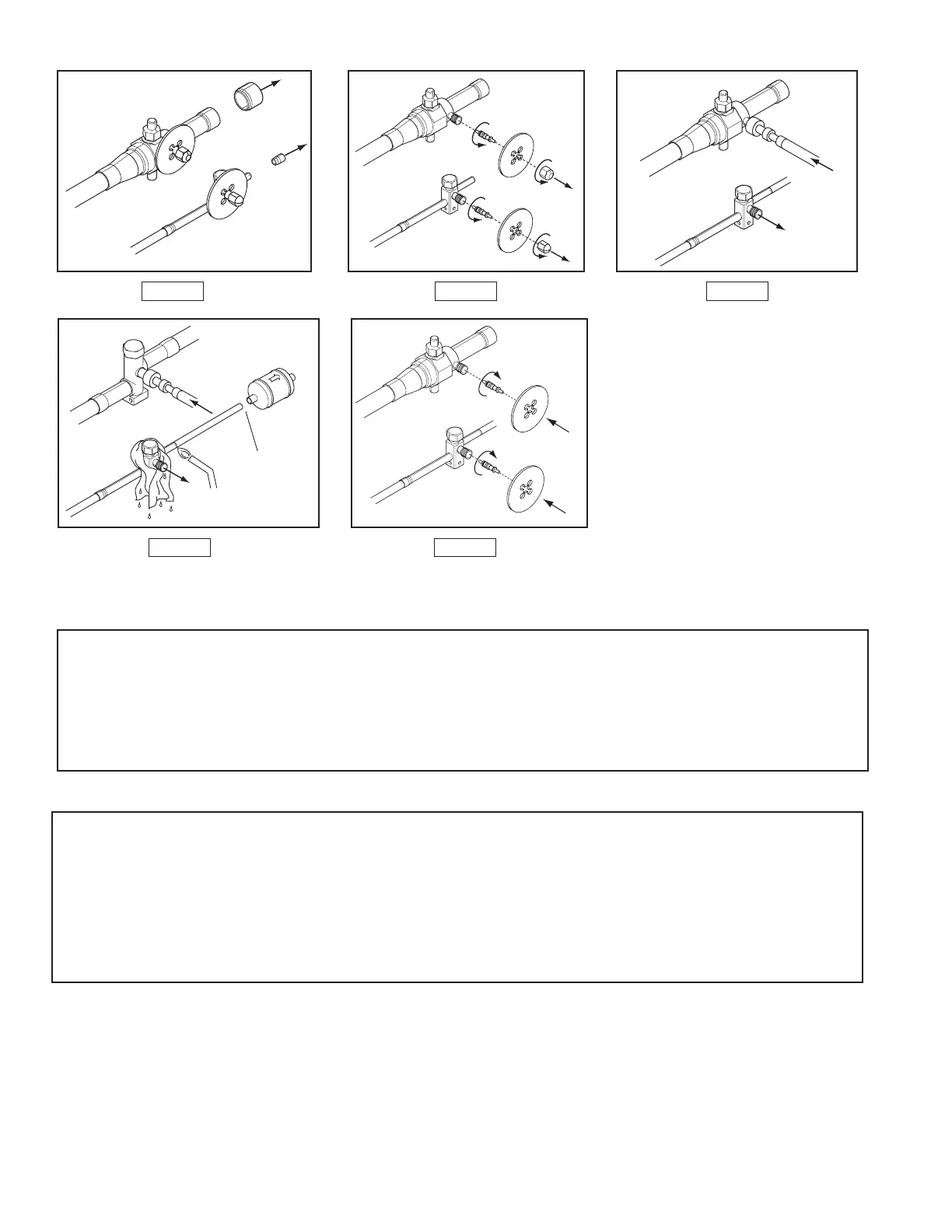

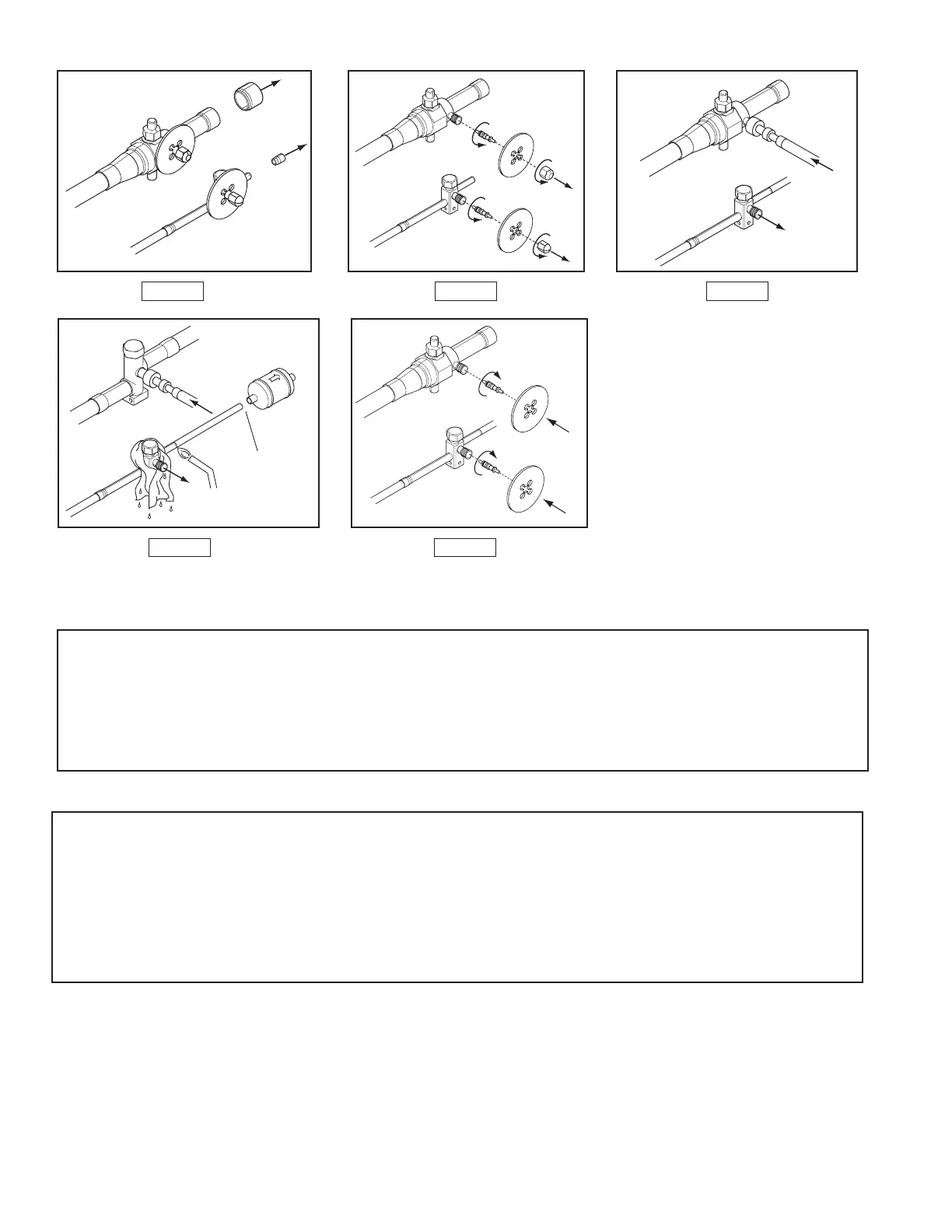

STEP 1 STEP 2 STEP 3

STEP 4 STEP 5

Section 8. Refrigerant Line Leak Check

After completion of eld piping for split systems, the eld pipework shall be pressure tested with nitrogen and then

vacuum tested prior to refrigerant charging.

Important: Under no circumstances shall potential sources of ignition be used in the searching for or detection of

refrigerant leaks.

Important: The following leak detection methods are deemed acceptable for all refrigerant systems:

• Electronic leak detectors calibrated for R-454B (with a sensitivity of 5 grams/year).

STEP 1 - Pressurize the refrigerant lines and evaporator coil to 150 PSIG using dry nitrogen.

STEP 2 - Check for leaks by using a soapy solution or bubbles at each brazed location.

NOTE: Remove nitrogen pressure and repair any leaks before continuing.

STEP 3 - Once the initial leak check is complete, complete a system pressure test. Pressurize the system to the

outdoor nameplate pressure for a minimum of 60 minutes. Do not add additional refrigerant or test gas after reach-

ing the design pressure. The system should show no loss of pressure once pressurized. Once the pressure test is

complete follow the steps for evacuation.

8.1 Check For Leaks

Loading...

Loading...