PKG-SVP01B-EN 9

General

InformationProgramming

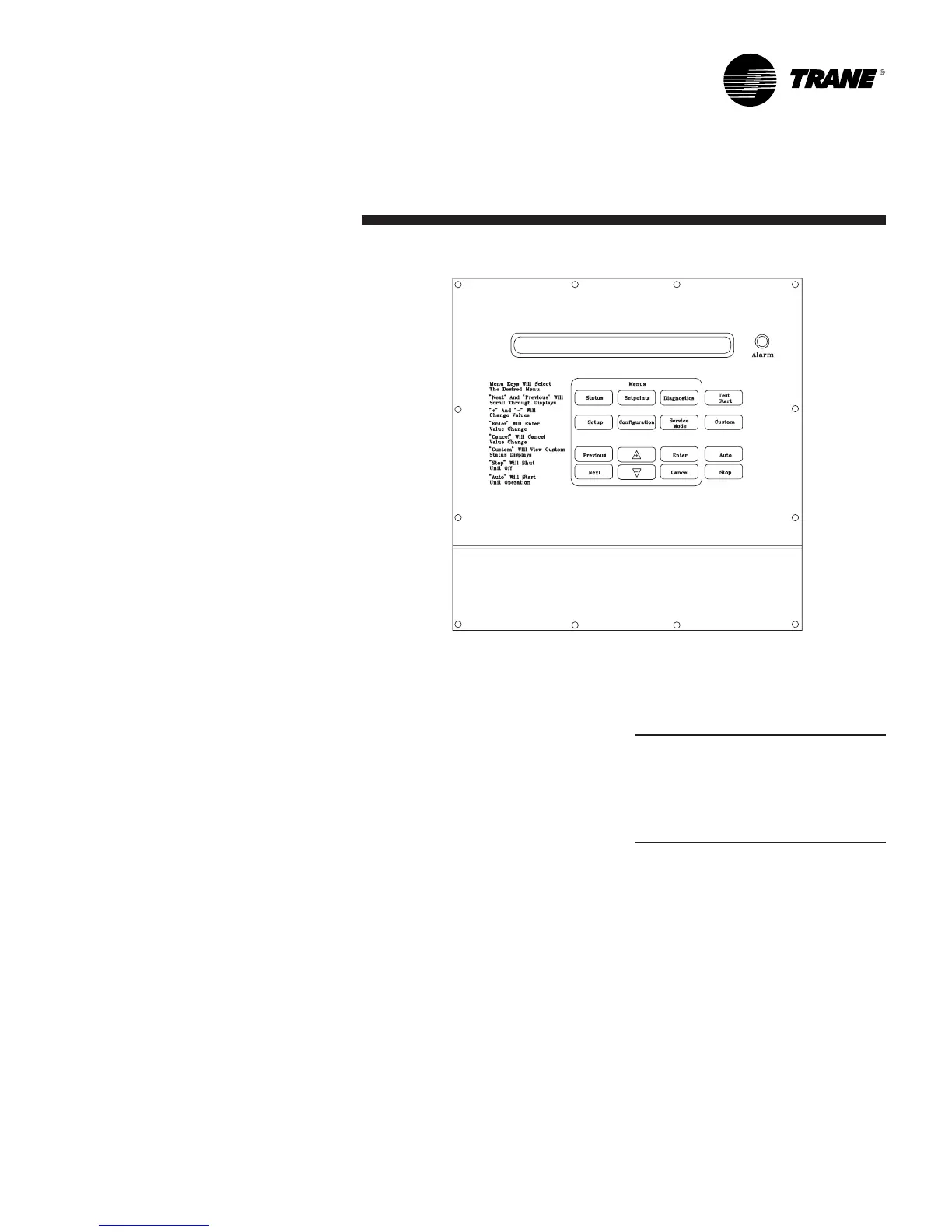

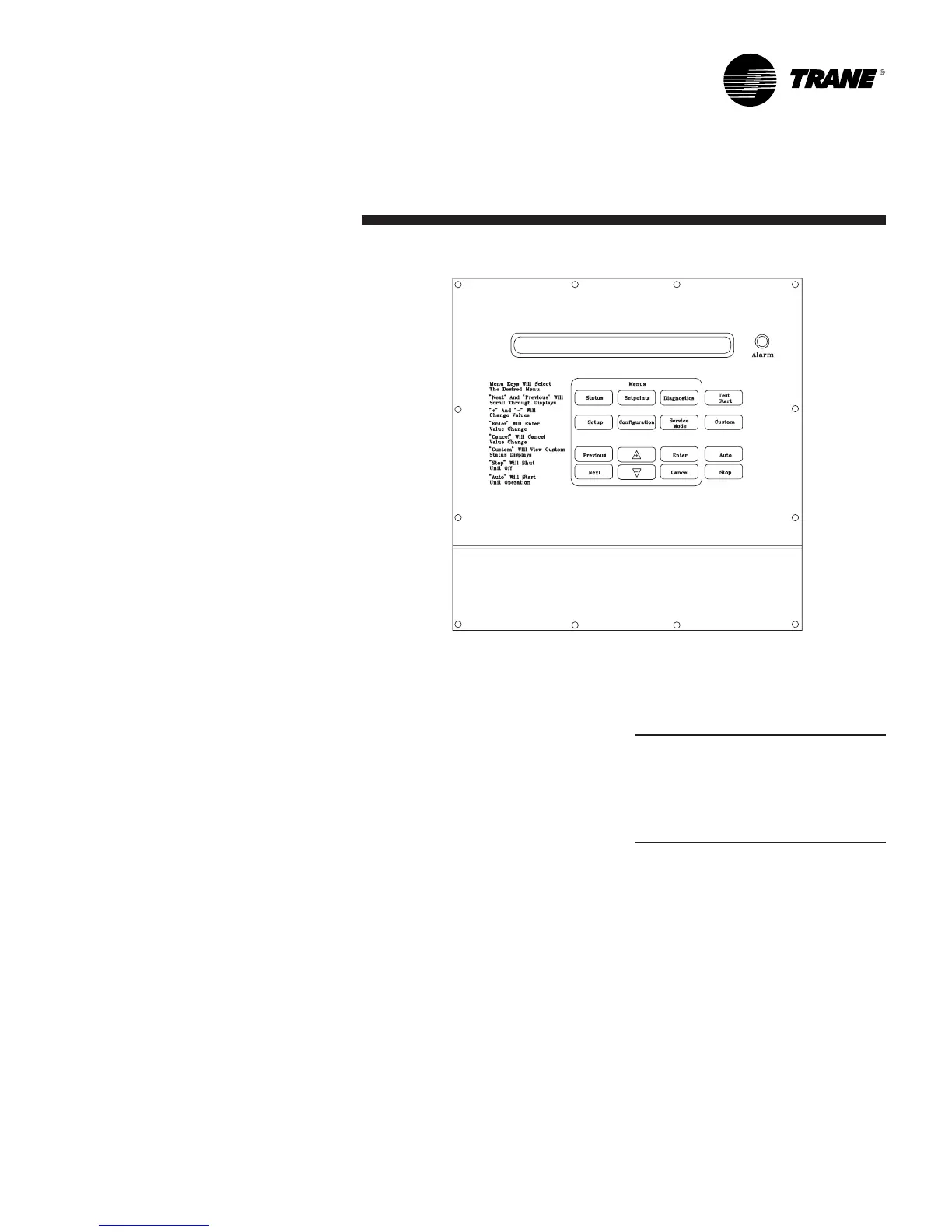

Figure P-GI-1. Human interface module.

Programming the Unit

The UCM must be programmed with

“job-specific”setup information for the

unit to operate and function properly. The

data necessary for unit operation will

vary depending on factors such as unit

size, type, and options.

This manual provides step by step

instructions for programming setup

information using the HI or RHI. It also

includes instructions for checking unit

operating status, accessing and clearing

diagnostics, and performing service tests.

Some of the displays in this manual may

not appear on the HI or RHI screen during

programming. Only applicable screens

for specific unit options and operating

parameters will display.

Any steps that do not apply to all unit

types are marked accordingly. Ignore any

steps that do not apply to your unit and/or

application. Continue this process until all

applicable screens are programmed with

the required information.

Menu Keys

Any references in this section to the HI

applies to both the HI and RHI, with the

exception of the SERVICE MODE key.

Reference Figure P-GI-2 for an illustration

of the six menu keys. The menu keys are:

STATUS, SETPOINTS, SETUP, CONFIGU-

RATION, DIAGNOSTICS, and SERVICE

MODE. These keys allow access to

various interactive menus so the user

can input and access unit operating data.

Pressing these keys will display the initial

menu screen designated by the key’s

name. The following information de-

scribes each key and its function.

If no key is pressed for 30 minutes while

the HI is displaying a menu screen, it will

revert back to the unit operating status

screen.

STATUS Key

Pressing the status key displays the

operating status screen: On, Unit Stop,

External Stop, Emergency Stop, or

Service Mode. Pressing the NEXT key

allows the operator to scroll to screens

that provide information such as air and

refrigerant temperatures, humidity

levels, fan operation, compressor

operation, heater operation, economizer

positioning, exhaust operation, and

heating, cooling, and compressor lockout

setpoints. Pressing the STATUS key while

viewing any of the data screens will

cause the HI to go back to the operating

status screen.

SETPOINTS Key

Pressing the SETPOINTS key displays the

first of the setpoint screens, allowing the

user to designate default temperatures

and pressure setpoints. While scrolling

through the setpoint screens, pressing

this key again will cause the LCD to

display the first setpoint screen.

DIAGNOSTICS Key

Pressing the DIAGNOSTICS key at any

time will allow the user to view any unit

function failures. The LCD screen will

display one of the diagnostic screens

(depending on which diagnostic, if any, is

present). If no key is pressed for 30

minutes while the screen is displaying

diagnostic information, it will revert back

to the operating status display.

CONFIGURATION Key

Pressing the CONFIGURATION key

displays the first of the configuration

screens. This allows the user to view or

designate unit configuration data such as

unit type, capacity, system control, etc

Pressing the configuration key at any

level in the configuration menu will

display the first configuration screen.

Note: Unit configuration information is

factory-programmed. Use this key only to

view current configuration data, or to

designate new data if the unit’s configura-

tion data is lost or if new options are added

in the field.

SETUP Key

Pressing the SETUP key displays screens

that designate various operating param-

eters such as temperature and pressure

ranges, limits, percentages, setpoint

source selections, and sensor input

definitions for the control of the unit’s

various operating modes. Pressing the

SETUP key at any level in the SETUP

menu will display the first SETUP screen.

SERVICE MODE Key

Pressing the SERVICE MODE key displays

the first of the service test mode screens

that allow the user to turn on or off

various unit components for a particular

test being performed. After designating

on/off status, a screen will display

requesting the user to designate the

TEST START time delay for each test.

Loading...

Loading...